Fluorinated nano-aluminum powder containing energy storage fuel

A technology of nano-aluminum powder and fluorinated nano-technology, which is applied in the field of energy storage fuels containing fluorinated nano-aluminum powder, can solve the problems of reducing the special properties of nano-powders, reducing fuel combustion efficiency, affecting fuel energy performance, etc., and achieving anti-settling Excellent performance, less residue, stable long-term storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

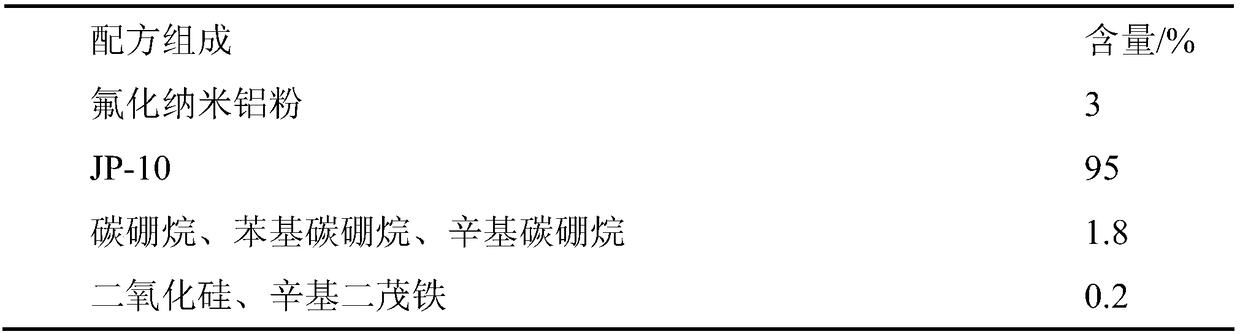

[0041] (1) Composition of fuel composition

[0042]

[0043] (2) Propellant performance

[0044]

[0045] Can know from embodiment 1, measured volume calorific value=41.7MJ L -1 (greater than 41MJ·L -1 ), density = 0.951g cm -3 (ρ20℃>0.9g·cm -3 ), combustion efficiency = 99.5%, capable of rapid ignition and high-efficiency combustion; residue amount = 0%, and has the advantage of no residue in combustion products.

Embodiment 2

[0047] (1) Composition of fuel composition

[0048]

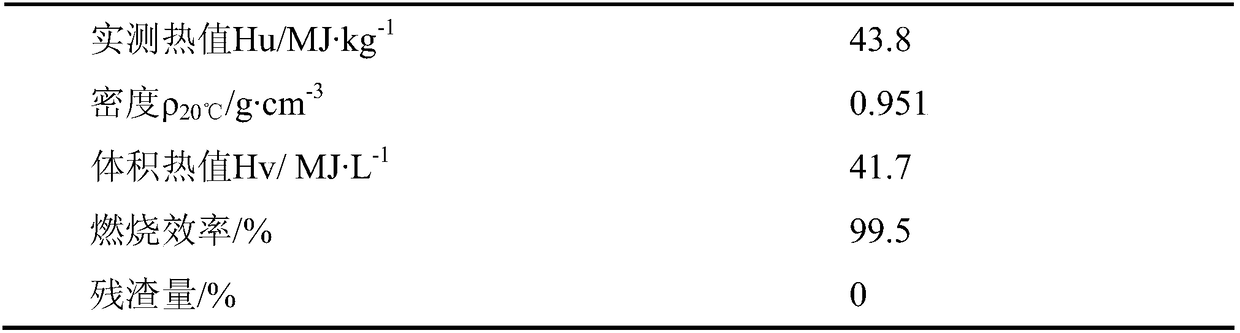

[0049] (2) Propellant performance

[0050]

[0051]

[0052] It can be known from Example 2 that when the liquid hydrocarbon fuel content in the fuel formula is 0, the measured volume calorific value=46.55MJ L -1 (greater than 41MJ·L -1 ), density = 0.931g cm -3 (ρ20℃>0.9g·cm -3 ), combustion efficiency = 98.5%, capable of rapid ignition and high-efficiency combustion; residue amount = 0.1%, and has the advantage of low residue in combustion products.

Embodiment 3

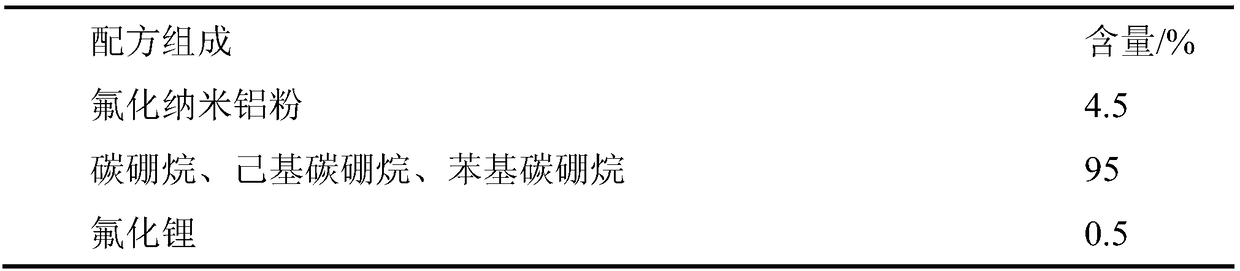

[0054] (1) Composition of fuel composition

[0055]

[0056] (2) Propellant performance

[0057]

[0058] As can be known from Example 3, when the carborane content in the fuel formulation was 0, the measured calorific value=43.7

[0059] MJ L -1 (greater than 41MJ·L -1 ), density=1.058g cm -3 (ρ20℃>0.9g·cm 3 ), combustion efficiency = 99.5%, capable of rapid ignition and high-efficiency combustion; residue amount = 0%, and has the advantage of no residue in combustion products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com