Hafnium diboride-zirconium diboride-based high-temperature solar energy absorbing coating and preparation method thereof

A solar energy absorption, hafnium diboride technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve problems such as unfavorable industrial production, cumbersome preparation method of solar energy absorption coating, etc., to shorten the production cycle , broad practical value and application prospects, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

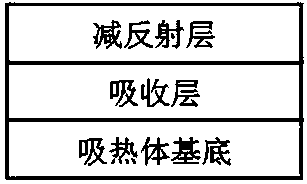

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a hafnium diboride-zirconium diboride-based high-temperature solar energy absorbing coating, specifically according to the following steps:

[0025] Step 1: Preparation of the absorbing layer: use hafnium diboride and zirconium diboride with a purity of 99.99% as sputtering targets, and pre-evacuate the vacuum chamber to a background vacuum of 1.5×10 -6 Torr. Hafnium diboride adopts DC magnetron sputtering technology, and zirconium diboride adopts radio frequency magnetron sputtering technology. Adjust the sputtering power density of the hafnium diboride target to 2 W / cm -2 , the sputtering power density of zirconium diboride is 3W / cm -2 . During the sputtering deposition, the intake of argon gas was 20 sccm, and the absorption layer was deposited on the stainless steel substrate (roughness 4 nm) by double-target co-sputtering technology, with a thickness of 40 nm; during the sputtering process, the substrate temperature was 100 o c.

[002...

Embodiment 2

[0030] A method for preparing a hafnium diboride-zirconium diboride-based high-temperature solar energy absorbing coating, specifically according to the following steps:

[0031] Step 1: Preparation of the absorbing layer: use hafnium diboride and zirconium diboride with a purity of 99.99% as sputtering targets, and pre-evacuate the vacuum chamber to a background vacuum of 6.0×10 -6 Torr. Hafnium diboride adopts DC magnetron sputtering technology, and zirconium diboride adopts radio frequency magnetron sputtering technology. Adjust the sputtering power density of the hafnium diboride target to 5 W / cm -2 , the sputtering power density of zirconium diboride is 7W / cm -2 . During the sputtering deposition, the intake of argon gas was 80 sccm, and the absorption layer was deposited on the nickel-based alloy substrate (roughness 8 nm) by double-target co-sputtering technology, with a thickness of 120 nm; during the sputtering process, the substrate temperature for 250 o c.

...

Embodiment 3

[0036] A method for preparing a hafnium diboride-zirconium diboride-based high-temperature solar energy absorbing coating, specifically according to the following steps:

[0037] Step 1: Preparation of the absorbing layer: use hafnium diboride and zirconium diboride with a purity of 99.99% as sputtering targets, and pre-evacuate the vacuum chamber to a background vacuum of 4.5×10 -6 Torr. Hafnium diboride adopts DC magnetron sputtering technology, and zirconium diboride adopts radio frequency magnetron sputtering technology. Adjust the sputtering power density of hafnium diboride target to 3.8 W / cm -2 , the sputtering power density of zirconium diboride is 4.9 W / cm -2 . The argon intake during sputtering deposition was 35 sccm, and the absorption layer was deposited on a stainless steel substrate (roughness 5 nm) by double-target co-sputtering technology, with a thickness of 75 nm; during the sputtering process, the substrate temperature was 200 o c.

[0038] Step 2: Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com