Control system and method for preparation and drying process of high volatile pulverized coal

A technology with high volatile content and drying process, applied in the direction of block/powder fuel preparation, combustion method, drying solid materials, etc., can solve the problems of high ignition point, fluctuation of production drying load, non-automatic control, etc., and achieve high efficiency in the control process , Reduce exhaust emissions and avoid heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

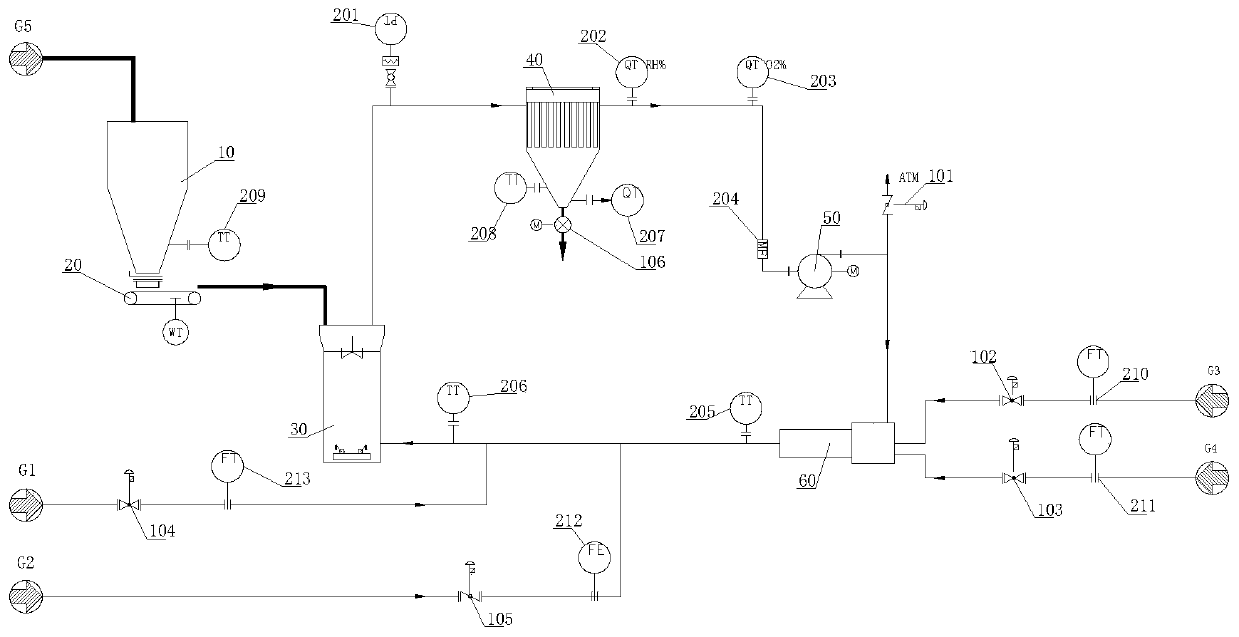

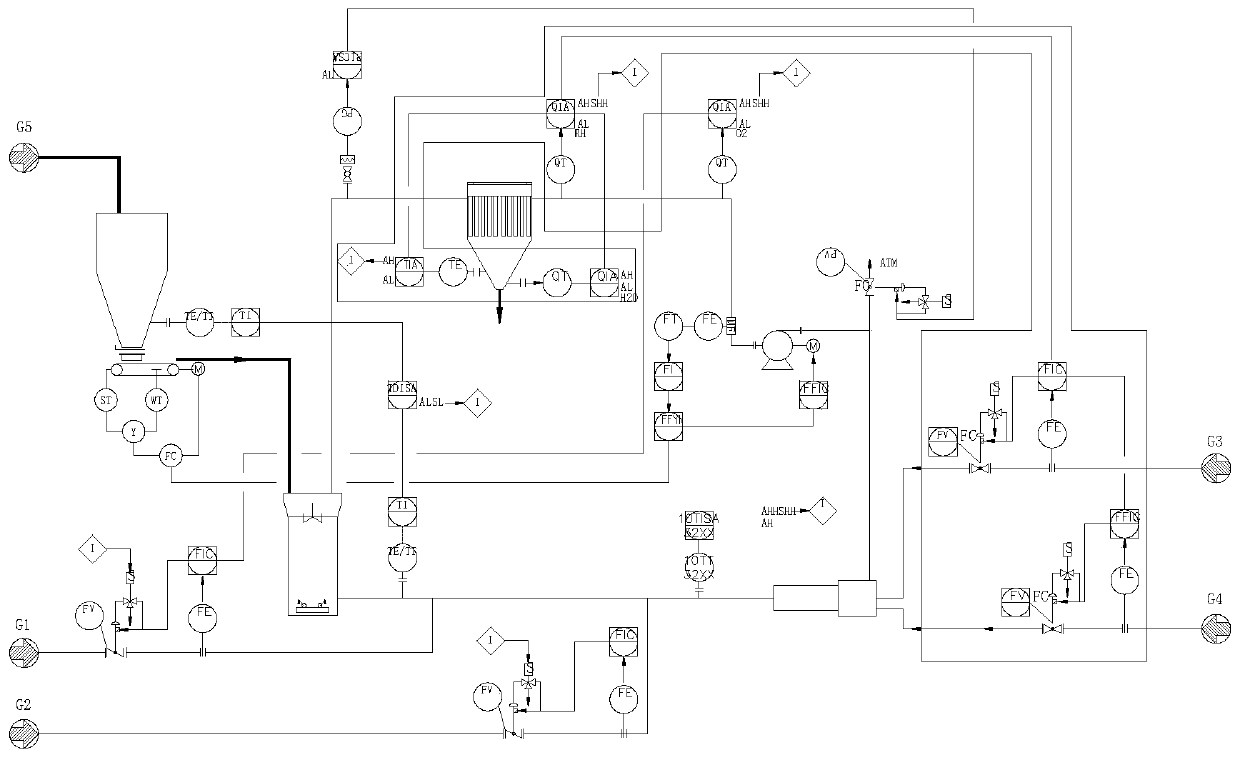

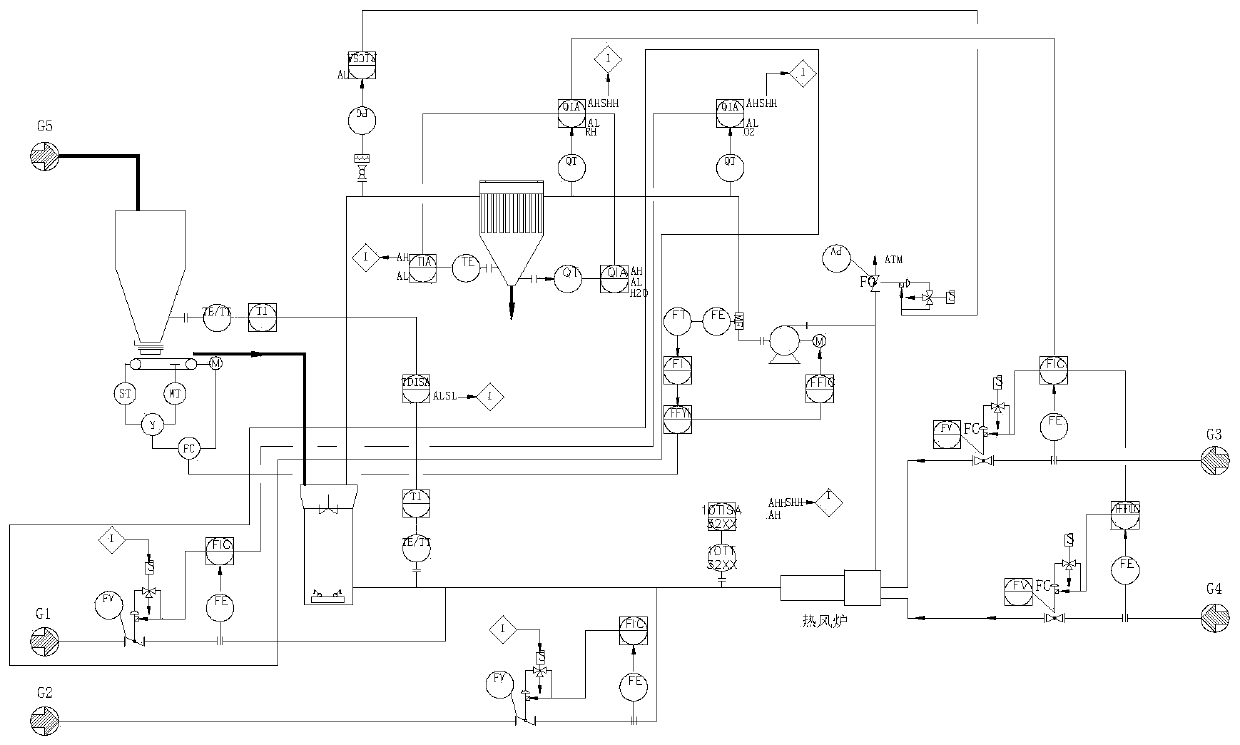

Image

Examples

Embodiment 1

[0066] A 400t / d dry pulverized coal gasification plant, wherein the high volatile pulverized coal preparation and drying control system of the present invention provides pulverized coal with qualified particle size and moisture for the gasification unit in the plant. The raw coal is lignite coal, dry basis The volatile matter is 42.3%, the moisture content is 28.3%, and the moisture content of the pulverized coal is controlled at 2% after drying.

[0067] The specific pulverized coal preparation and drying steps are as follows:

[0068] (1) After coal pulverization, drying and feeding test run, through the online monitoring of the thermometer I value of the finished coal powder in the ash hopper of the coal powder collector, and real-time monitoring of the temperature value, the inert gas at the outlet of the coal powder collector is relatively online The relative humidity value of the humidity analyzer (RH%); when the value of the online relative humidity analyzer > the prese...

Embodiment 2

[0076] A 700t / d dry pulverized coal gasification plant, wherein the high volatile pulverized coal preparation and drying control system of the present invention provides pulverized coal with qualified particle size and moisture for the gasification unit in the plant. The raw coal is bituminous coal, dry basis The volatile matter is 7.27%, the moisture content is 6.1%, and the moisture content of pulverized coal is controlled to 2% after drying.

[0077] The specific pulverized coal preparation and drying steps are as follows:

[0078] (1) After coal pulverization, drying and feeding test run, through the on-line monitoring of the thermometer I value of the temperature of the finished coal powder in the ash hopper of the coal powder collector, and real-time monitoring of the temperature value, the outlet of the coal powder collector circulates inert gas The relative humidity value of the online relative humidity analyzer (RH%); when the value of the online relative humidity ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com