Preparation method for standard sample of polycyclic aromatic hydrocarbons in PP (Polypropylene) plastic

A standard sample, polycyclic aromatic hydrocarbon technology, applied in the field of preparation of polycyclic aromatic hydrocarbon standard samples, can solve problems such as large error and uneven mixing, and achieve the effects of reducing errors, ensuring uniformity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

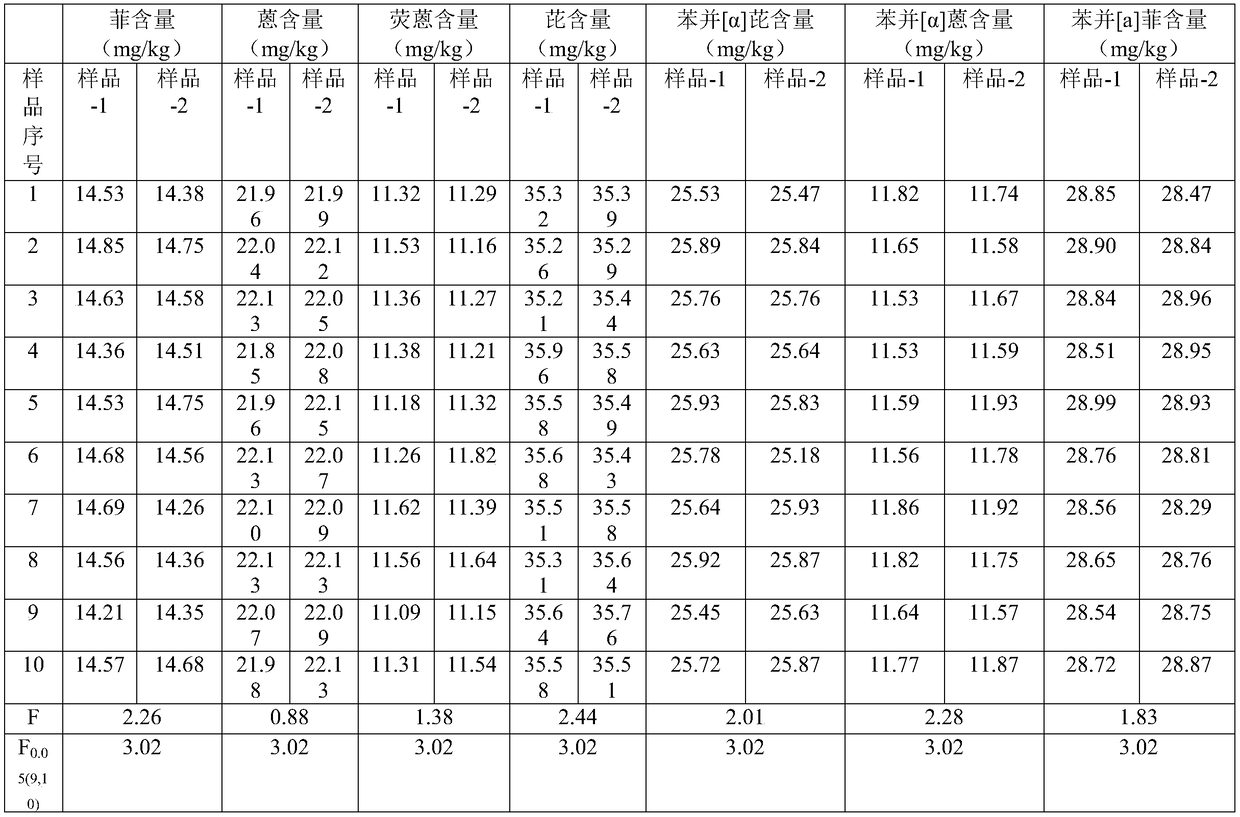

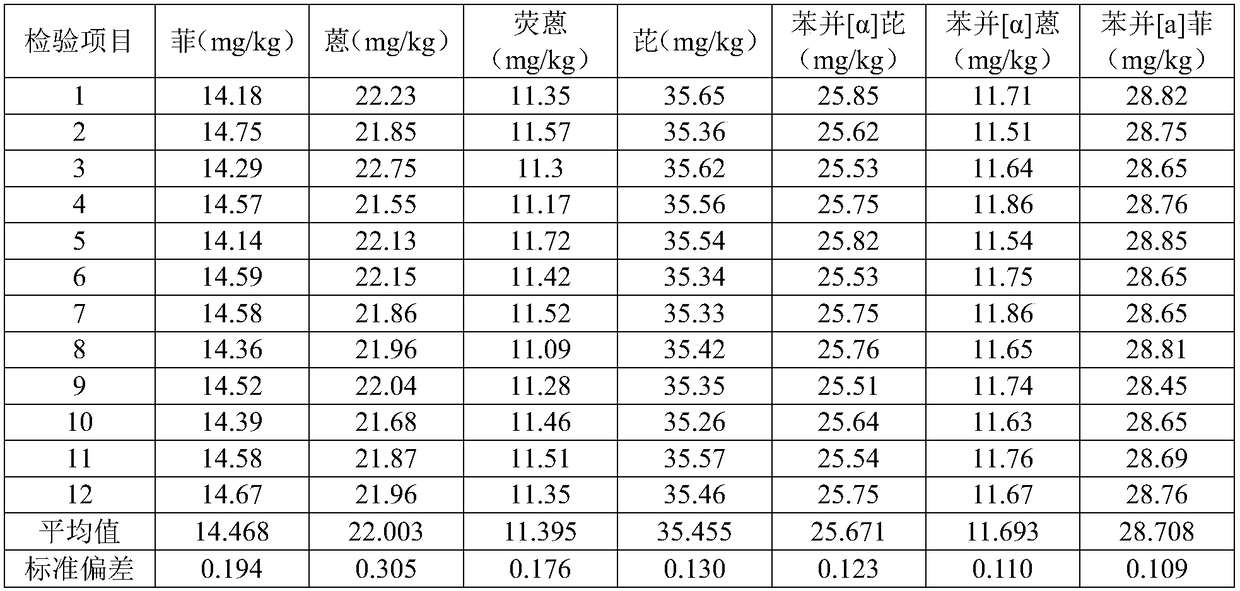

Embodiment 1

[0036] The content of phenanthrene is 15mg / kg, the content of anthracene is 21mg / kg, the content of fluoranthene is 12mg / kg, the content of pyrene is 33mg / kg, the content of benzo[α]pyrene is 25mg / kg, and the content of benzo[α]anthracene is 12mg / kg, benzo[a]phenanthrene content is the preparation process of PP-based standard substance of 28mg / kg:

[0037] 1. Preparation of blank standard samples

[0038] 1.1 Take PP resin (HP500) 4465g; PP powder (150 powder) 500g, stabilizer A (X-001) 5g, stabilizer B (X-002) 10g, lubricant (O-W01) 20g, add to the high mixer medium, stir.

[0039] 1.2 Heat and melt the mixture at a temperature of 200°C, extrude the mixture with an extruder and pelletize it in a pelletizer.

[0040] 2. Preparation of Concentrated Masterbatch (PP-MA)

[0041] 2.1 Weigh 0.975g of target phenanthrene, 1.365g of anthracene, 0.78g of fluorescein, 2.145g of pyrene, 1.625g of benzo[α]pyrene, 0.78g of benzo[α]anthracene, 1.82g of benzo[a]phenanthrene and use Sol...

Embodiment 2

[0060] The preparation process of the PP-based standard substance whose content is 65mg / kg of naphthalene, phenanthrene, anthracene, fluoranthene and pyrene:

[0061] 1. Preparation of blank standard samples

[0062] 1.1 Take PP resin (HP500) 4465g; PP powder (150 powder) 500g, stabilizer A (X-001) 5g, stabilizer B (X-002) 10g, lubricant (O-W01) 20g, add to the high mixer medium, stir.

[0063] 1.2 Heat and melt the mixture at a temperature of 200°C, extrude the mixture with an extruder and pelletize it in a pelletizer.

[0064] 2. Preparation of Concentrated Masterbatch (PP-MA)

[0065] 2.1 Weigh 6.5g of target substances (naphthalene, phenanthrene, anthracene, fluoranthene, pyrene) and dissolve them in 50-100ml of solvent (organic solvents such as toluene and acetone) to prepare a mixed solution;

[0066] 2.2 Weigh 500g of PP powder, 5g of stabilizer A (X-001), 10g of stabilizer B (X-002), 20g of lubricant (O-W01), and mix well;

[0067] 2.3 Mix the mixture of 2.1 and 2....

Embodiment 3

[0085] The preparation process of the PP-based standard substance whose content is 100mg / kg of naphthalene, phenanthrene, anthracene, fluoranthene and pyrene:

[0086] 1. Preparation of blank standard samples

[0087] 1.1 Take PP resin (HP500) 4465g; PP powder (150 powder) 500g, stabilizer A (X-001) 5g, stabilizer B (X-002) 10g, lubricant (O-W01) 20g, add to the high mixer medium, stir.

[0088] 1.2 Heat and melt the mixture at a temperature of 200°C, extrude the mixture with an extruder and pelletize it in a pelletizer.

[0089] 2. Preparation of Concentrated Masterbatch (PP-MA)

[0090] 2.1 Weigh 10.0g of the target substance (naphthalene, phenanthrene, anthracene, fluoranthene, pyrene) and dissolve them in 50-100ml of solvent (toluene, acetone and other organic solvents) to prepare a mixed solution;

[0091] 2.2 Weigh 500g of PP powder, 5g of stabilizer A (X-001), 10g of stabilizer B (X-002), 20g of lubricant (O-W01), and mix well;

[0092] 2.3 Mix the mixture of 2.1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com