Positive electrode active material and preparation method thereof, all-solid lithium battery

A positive electrode active material and a positive electrode technology are applied in the fields of all-solid-state lithium batteries, positive-electrode active materials and their preparation, and can solve the problem of decreasing the ion conductivity of all-solid-state lithium batteries, reducing the reversibility of all-solid-state lithium batteries, and reducing the capacity of all-solid-state lithium batteries. and other problems, to achieve the effect of improving the specific capacity and cycle stability of the battery, improving the cycle stability and specific capacity, and improving the cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to a second aspect of the present invention, the present invention provides a method for preparing a positive electrode active material, comprising the steps of:

[0041] Mixing nano-ferrous sulfide and carbon-containing high polymer to obtain nano-ferrous sulfide coated with carbon-containing high polymer, and sintering to obtain positive electrode active material;

[0042] Wherein, the positive electrode active material includes nano ferrous sulfide and a carbon layer covering the nano ferrous sulfide.

[0043] The preparation method of the positive electrode material of the all-solid-state lithium battery provided by the invention has simple process, convenient operation, can carry out large-scale industrial production, improves production efficiency, and reduces preparation cost.

[0044] In a preferred embodiment of the present invention, the carbon-containing high polymer includes but not limited to one or more of polyvinylpyrrolidone, polyethylene glyco...

Embodiment 1

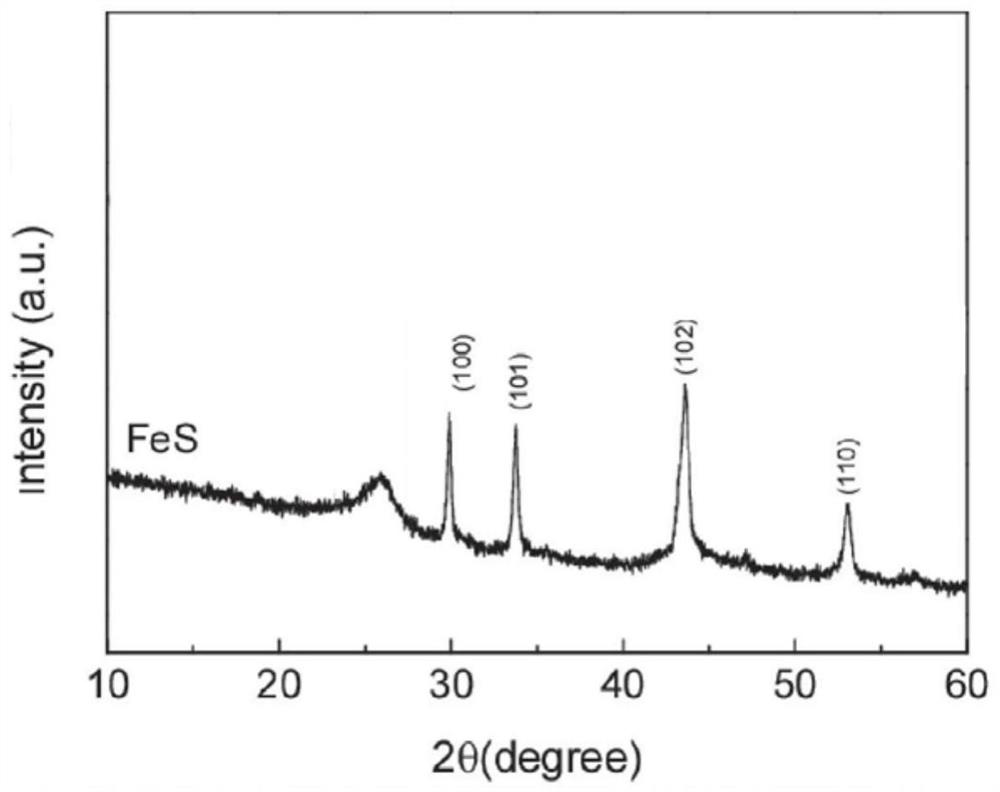

[0070] This embodiment provides a positive electrode material for an all-solid-state lithium battery, including nano-ferrous sulfide and a carbon layer coated with nano-ferrous sulfide, which is prepared according to the following steps:

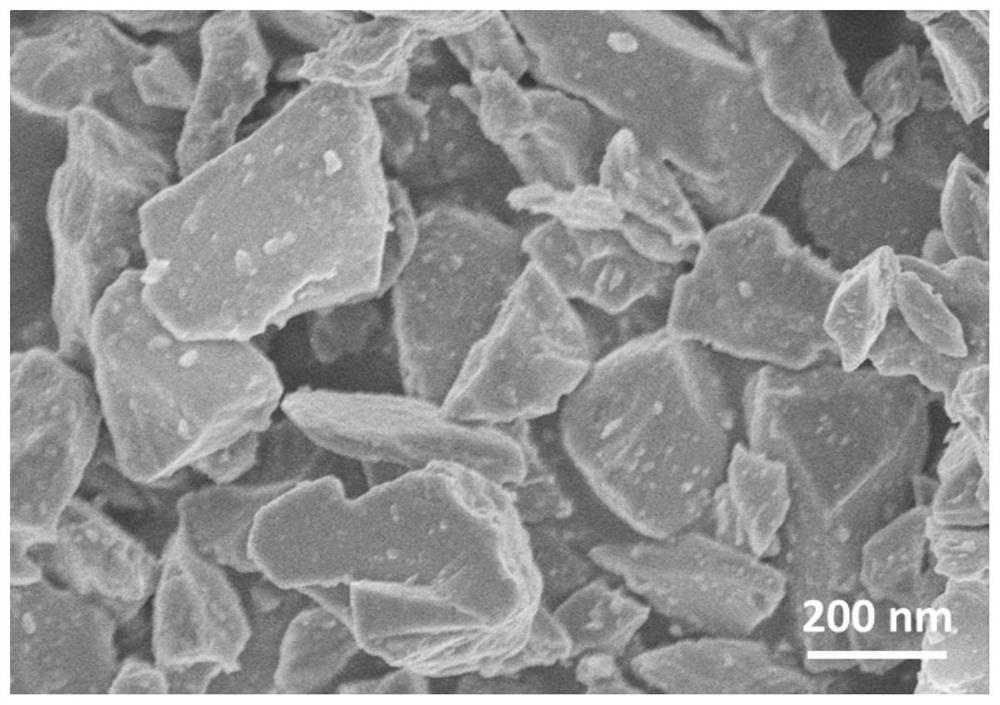

[0071] (1) Place commercialized ferrous sulfide with a particle size of more than 10 microns in a zirconia ball mill tank under the protection of argon, and ball mill it for 32 hours at a speed of 700 rpm to obtain nanometer ferrous sulfide particles with a particle size of 100-500 nm ;

[0072] (2) Dissolve polyvinylpyrrolidone (PVP) in N,N dimethylformamide (DMF) and disperse evenly, then add nano ferrous sulfide particles, stir magnetically for 6 hours, and distill under reduced pressure to remove DMF to obtain PVP coated nano The precursor particle of ferrous sulfide; Wherein, the mass ratio of nano ferrous sulfide and PVP is 95:5;

[0073] (3) The precursor particles were heated at 400° C. for 1 hour, and then sintered at 800° C. for 1...

Embodiment 2

[0075] This embodiment provides a positive electrode active material, including nano-ferrous sulfide and a carbon layer coated with nano-ferrous sulfide. The difference between its preparation method and Example 1 is that in step (1), a 10-micron The above ferrous sulfide is ball milled into nano ferrous sulfide with a particle size of 50-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com