Welding line strength control method for magnesium alloy multilayer and multichannel laser overlaying

A multi-layer, multi-channel, laser surfacing welding technology, which is applied in the direction of laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as no instructions or reports found, no data collected, etc., to achieve repair welding Weld strength and uniformity, compact structure, and good temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

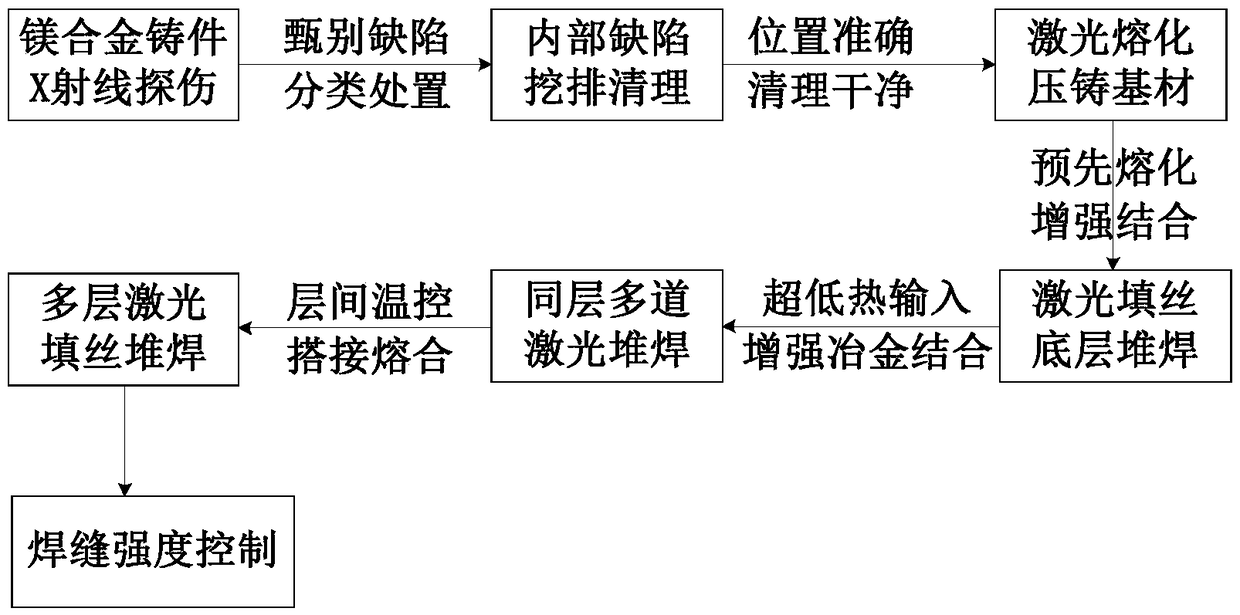

[0054] as attachedfigure 1 As shown, a method for controlling the weld strength of magnesium alloy multi-layer multi-pass laser surfacing welding comprises the following steps:

[0055] Step 1. According to the X-ray flaw detection results of magnesium alloy castings, identify the types of internal defects in the castings, clarify the distribution of defects, and completely remove the defects by machining. After cleaning, the inclination angle of the side wall of the pit is ≥ 15°, which meets the requirements for subsequent side wall welding, melting and bonding. ;

[0056] Step 2. Using the laser self-melting welding method with precise control of laser power, the laser beam melts the bottom of the substrate and the melting layer on the side wall to a depth of 2 to 4 mm, and releases the saturated gas on the surface of the die-casting substrate through the flow of the welding molten pool, eliminating the contact between the die-casting substrate and the surface of the die-cast...

Embodiment 2

[0066] According to the strength control requirements of multi-layer and multi-pass welds of magnesium alloy die-casting structural parts, the strength control method of magnesium alloy laser surfacing welding is adopted, and the method of low heat input laser surfacing welding is carried out to carry out multi-layer and multi-pass repair welding with strict control of interlayer temperature. Realize the weld strength and uniformity control of the repair welding layer. The aerospace magnesium alloy die-casting structure is complex, and it is difficult to avoid internal casting defects such as pores, inclusions, and looseness. This method uses magnesium alloy welding wire with matching strength, and uses a laser beam to melt the die-casting base material and filler wire synchronously. The mixed molten pool solidifies to form a metallurgical bond, and By controlling the interlayer temperature in the welding process, the strength control of the magnesium alloy multi-layer and mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com