A kind of sn-bi series low-silver lead-free solder alloy and preparation method thereof

A lead-free solder and alloy technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem of reducing the shear strength of solder joints and the life of anti-drop impact, the safety hazards of electronic product service reliability, and the lubrication of solder. Wet spreadability, reduced mechanical properties, etc., to achieve the effects of excellent wet spreadability, solidification segregation inhibition, and high microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

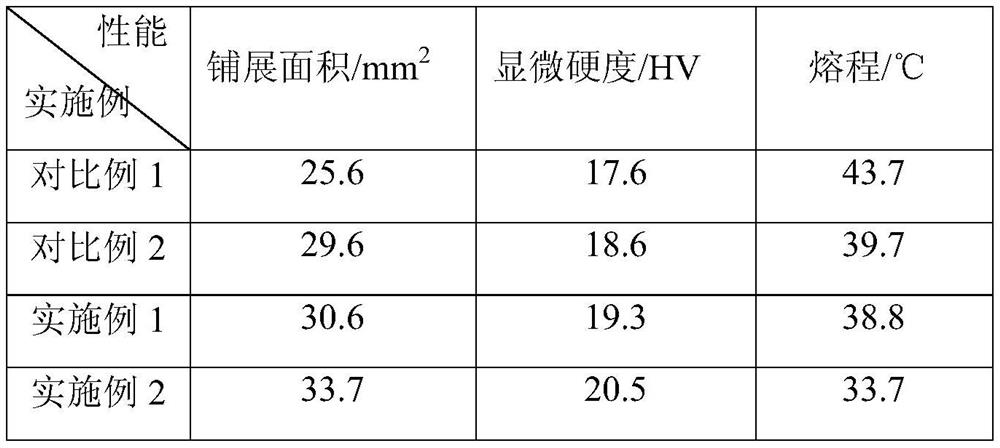

Examples

Embodiment 1

[0031] Take by weighing pure Sn (99.95%) and pure Bi (99.9%) and Sn-20Ag, Sn-20Cu alloy according to the proportion that the bismuth content is 40%, the silver content is 0.5%, the copper content is 0.5%, and the remainder is tin. Melted in a crucible in a resistance furnace. The feeding sequence during smelting is as follows: first put pure Sn into the crucible, then put pure Bi particles into the crucible after complete melting, and finally put Sn-20Ag and Sn-20Cu alloys. Configure 100g of each solder alloy according to the composition in Table 1, the melting temperature is 350°C, stir evenly after all the raw materials are melted, keep warm for 30 minutes, stir once every 10 minutes during the heat preservation process, add a small amount of rosin to the solder solution before casting, and remove the scale The residue was finally cast to obtain the solder alloy of this embodiment.

Embodiment 2

[0033] Take by weighing pure Sn (99.95%) and pure Bi (99.9%) and Sn-20Ag, Sn-20Cu alloy according to the proportion that the bismuth content is 40%, the silver content is 0.5%, the copper content is 1.5%, and the remainder is tin. Melted in a crucible in a resistance furnace. The feeding sequence during smelting is as follows: first put pure Sn into the crucible, then put pure Bi particles into the crucible after complete melting, and finally put Sn-20Ag and Sn-20Cu alloys. Configure 100g of each solder alloy according to the composition in Table 1, the melting temperature is 350°C, stir evenly after all the raw materials are melted, keep warm for 30 minutes, stir once every 10 minutes during the heat preservation process, add a small amount of rosin to the solder solution before casting, and remove the scale The residue was finally cast to obtain the solder alloy of this embodiment.

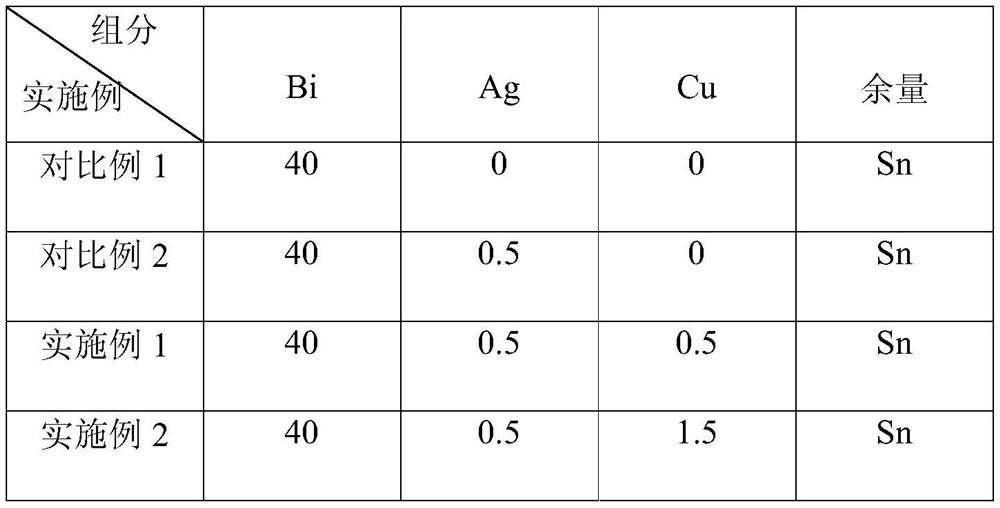

[0034] Table 1 Solder alloy chemical composition (wt.%)

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com