Refining method of atorvastatin parent nucleus M4

A technology of refining atorvastatin, which is applied in the refining field of atorvastatin core M4, which can solve the problems of low qualified rate of product refining at one time, affect production efficiency, increase product cost, etc., achieve large production capacity and increase production and good productivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

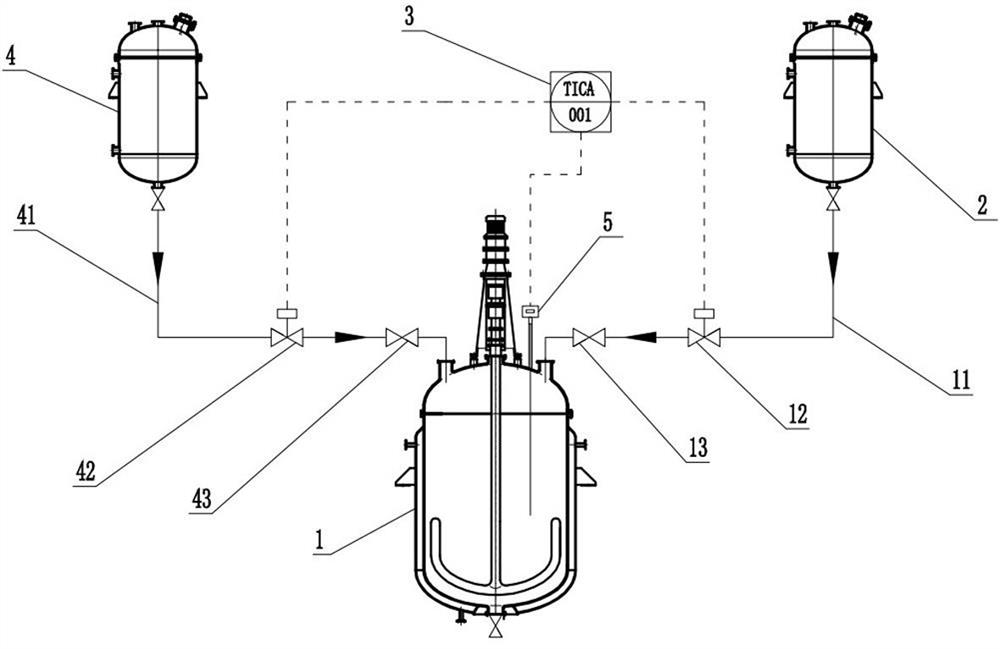

[0052] In the process of refining the crude atorvastatin core M4, it is necessary to add hydrochloric acid or glacial acetic acid to adjust the pH value of the reaction system, and it is necessary to precisely control the amount of hydrochloric acid or glacial acetic acid added. In this example, a DCS that can regulate the pH value is used. Reactor systems to regulate pH, such as figure 1 As shown, the DCS reactor system capable of regulating the pH value includes a reactor 1, a first adding tank 2, a second adding tank 4 and DCS control equipment;

[0053] The first adding tank 2 contains hydrochloric acid, and the second adding tank 4 contains glacial acetic acid;

[0054] The reactor 1 is provided with a stirring shaft and a stirring paddle, and the top cover of the reactor 1 is provided with a first feed port and a second feed port, and the output end of the first feed tank 2 is connected to the top of the reactor 1 through the first feed pipe 11. The first feeding port o...

Embodiment 2

[0070] A method for refining atorvastatin core M4, the specific steps are as follows;

[0071] (1) Add 1600kg of atorvastatin core M4 (i.e. compound VI) crude product 1 to the reactor with a volume of 5000L, then add 4800kg of water, stir and mix, and add dropwise hydrochloric acid to adjust the pH value. The DCS that regulates the pH value controls the reaction kettle system to control the dripping amount of hydrochloric acid, and sets the pH value range to 5.60-6.40. When the pH value is greater than the range value, open the first electric control valve 12 for hydrochloric acid dripping. When the pH value is 5.95, close the first electric control valve 12, stop dripping;

[0072] Then beat at room temperature for 2 hours, centrifuge, dry under reduced pressure, and control the moisture to ≤1%, to obtain 1486kg of atorvastatin mother nucleus M4 crude product 2, which was detected by HPLC, and the content of atorvastatin mother nucleus M4 in crude product 2 was 98.95% %, moi...

Embodiment 3

[0077] A method for refining atorvastatin core M4, the specific steps are as follows;

[0078] (1) Add 1600kg of atorvastatin core M4 (i.e. compound VI) crude product 1 to the reactor with a volume of 5000L, then add 4800kg of water, stir and mix, and add dropwise hydrochloric acid to adjust the pH value. The DCS that regulates the pH value controls the reaction kettle system to control the dripping amount of hydrochloric acid, and sets the pH value range to 5.60-6.40. When the pH value is greater than the range value, open the first electric control valve 12 for hydrochloric acid dripping. When the pH value is 6.10, close the first electric control valve 12, stop dripping;

[0079] Then beat at room temperature for 2 hours, centrifuge, dry under reduced pressure, and control the moisture to ≤1%, to obtain 1481 kg of atorvastatin mother nucleus M4 crude product 2, which was detected by HPLC, and the content of atorvastatin mother nucleus M4 in crude product 2 was 99.15% %, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com