A kind of ti-zr-cu-ni-co-mo amorphous solder and preparation method thereof

A technology of ti-zr-cu-ni-co-mo and brazing filler metal, which is applied in the field of Ti-Zr-Cu-Ni-Co-Mo amorphous brazing filler metal and its preparation, can solve the problem of increasing the dissolution degree of base metal and brazing filler metal High welding temperature, difficult to meet the problems of brazing, etc., to achieve the effect of increasing wettability, high connection strength, and reducing the difficulty of brazing assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

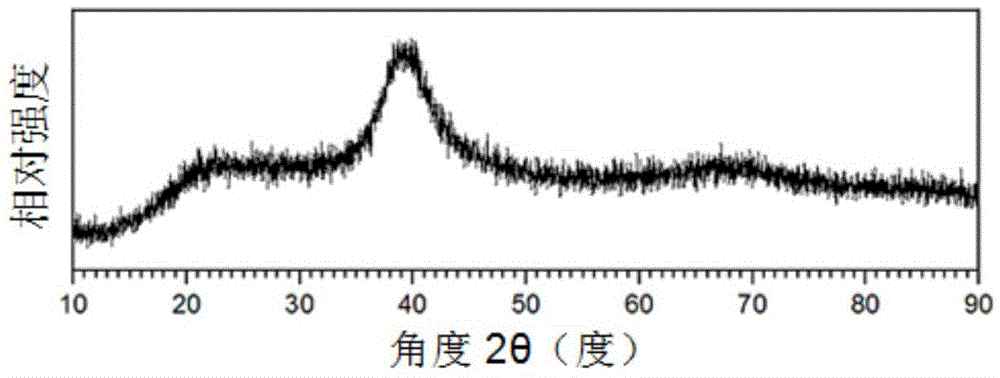

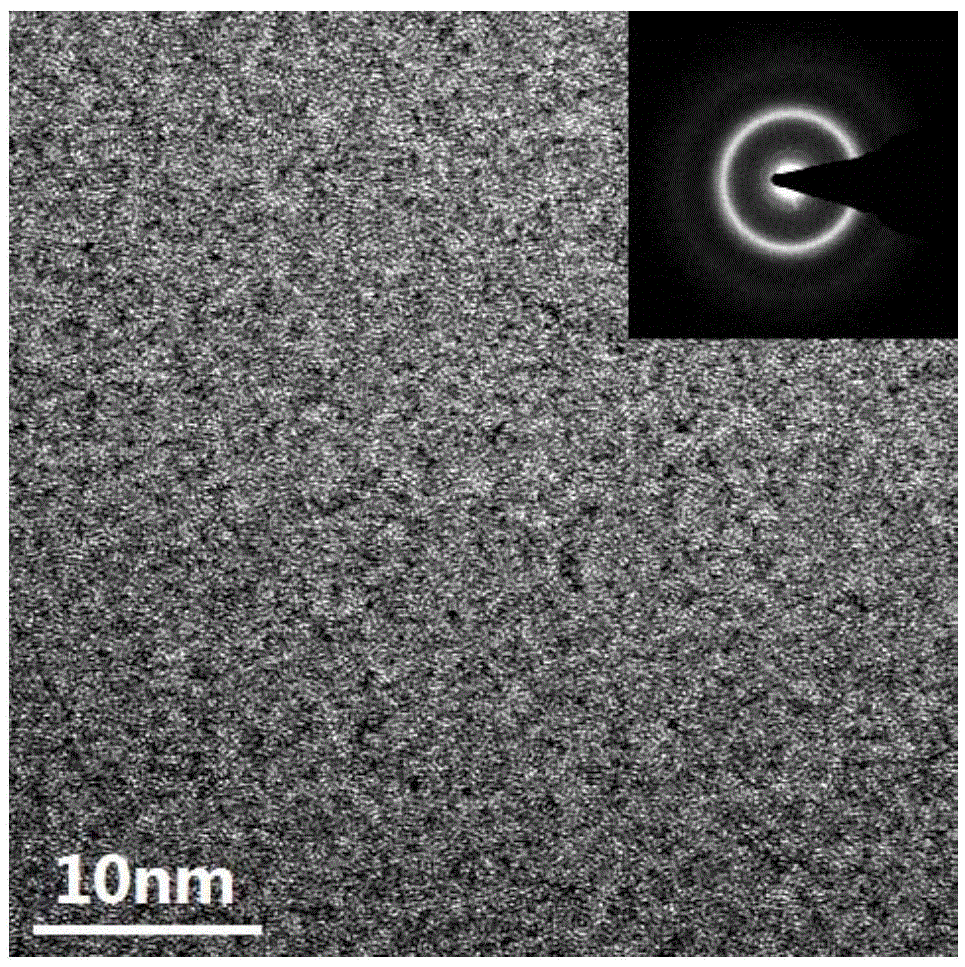

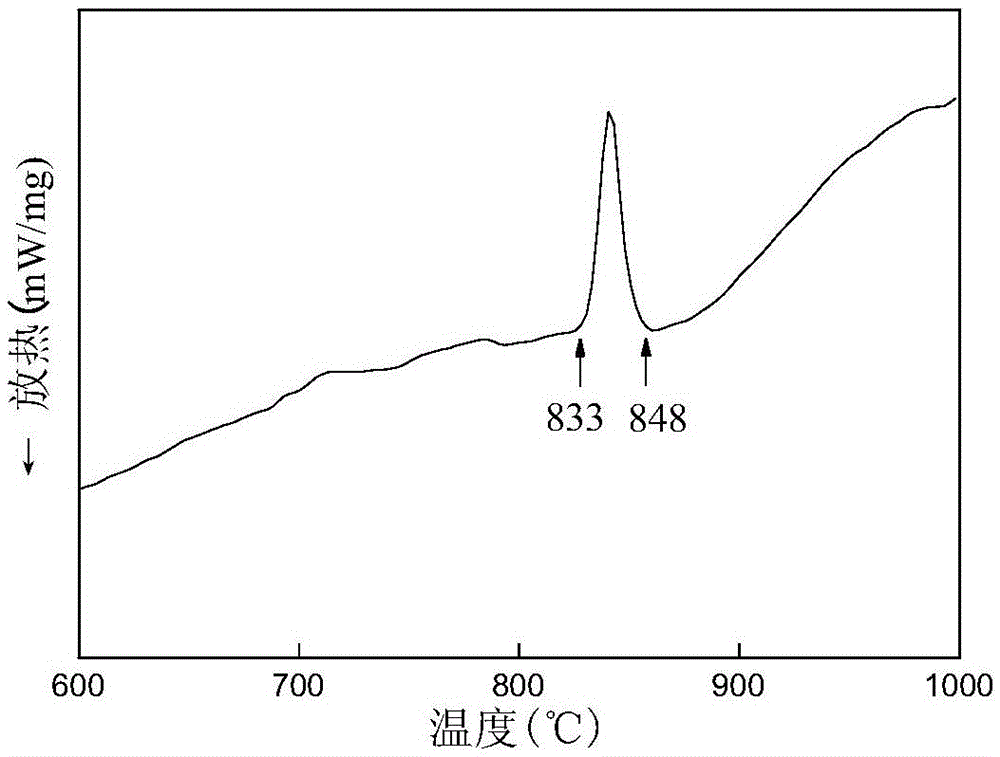

Image

Examples

Embodiment 1

[0031] (1) Ingredients: Ti, Zr, Cu, Ni, Co, Mo metal particles are used as raw materials, the purity of each raw material is ≥99.9%, and the content by mass percentage is Ti44.6%, Zr26.2%, Cu13. 6%, Ni12.6%, Co1.8%, Mo1.2% to prepare the charge, and remove the oxide film and impurities on the particle surface before batching, that is, use 1.5% HF-2.5% HNO 3 -5%HCl-91%H 2 O (Vol%) was first pickled, then soaked in 2mol / L NaOH solution for 5 minutes, then rinsed with absolute ethanol, dried, and finally ultrasonically cleaned in acetone for 10 minutes and then dried;

[0032] (2) Melting solder alloy: put the charge prepared in step (1) into the water-cooled copper crucible of the WS-4 non-consumable vacuum electric arc furnace, and first pump the vacuum in the furnace chamber to 4.5×10 -3 Fill Pa again with argon gas to 0.06MPa, repeat the operation for 3 times, and then use the current size of 150A tungsten arc melting for 5 times under the atmosphere of argon protection to o...

Embodiment 2

[0036] (1) Ingredients: Ti, Zr, Cu, Ni, Co, Mo metal particles are used as raw materials, the purity of each raw material is ≥99.9%, and the content by mass percentage is Ti43.7%, Zr25.65%, Cu13. 3%, Ni12.35%, Co3%, Mo2% to prepare the charge, and remove the oxide film and impurities on the particle surface before batching, that is, use 1.5% HF-2.5% HNO 3 -5%HCl-91%H 2 O (Vol%) was first pickled, then soaked in 2mol / L NaOH solution for 5 minutes, then rinsed with absolute ethanol, dried, and finally ultrasonically cleaned in acetone for 10 minutes and then dried;

[0037] (2) Melting solder alloy: put the furnace material prepared in step (1) into the water-cooled copper crucible of the WS-4 non-consumable vacuum electric arc furnace, and first pump the vacuum in the furnace chamber to 4×10 -3 Fill Pa again with argon gas to 0.055MPa, repeat the operation 4 times, and then use the current size of 140A tungsten arc melting 6 times under the atmosphere of argon protection to ob...

Embodiment 3

[0041] (1) Ingredients: Ti, Zr, Cu, Ni, Co, Mo metal particles are used as raw materials, the purity of each raw material is ≥99.9%, and the content by mass percentage is Ti42.8%, Zr25.1%, Cu13. 0%, Ni12.1%, Co4.2%, Mo2.8% to prepare the charge, and remove the oxide film and impurities on the particle surface before batching, that is, use 1.5% HF-2.5% HNO 3 -5%HCl-91%H 2 O (Vol%) was first pickled, then soaked in 2mol / L NaOH solution for 5 minutes, then rinsed with absolute ethanol, dried, and finally ultrasonically cleaned in acetone for 10 minutes and then dried;

[0042] (2) Melting solder alloy: put the furnace material prepared in step (1) into the water-cooled copper crucible of the WS-4 non-consumable vacuum electric arc furnace, and first pump the vacuum in the furnace chamber to 4×10 -3 Fill Pa again with argon to 0.065MPa, repeat the operation 5 times, and then use tungsten arc melting with a current size of 130A 6 times under the atmosphere of argon protection to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com