Ternary precursor in multiple crystal forms and preparation method of ternary precursor

A polycrystalline, precursor technology, applied in chemical instruments and methods, electrical components, structural parts, etc., can solve the problems of low magnification, low cycle, low capacity, etc., to improve comprehensive performance, simple and convenient operation, no equipment requirements. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

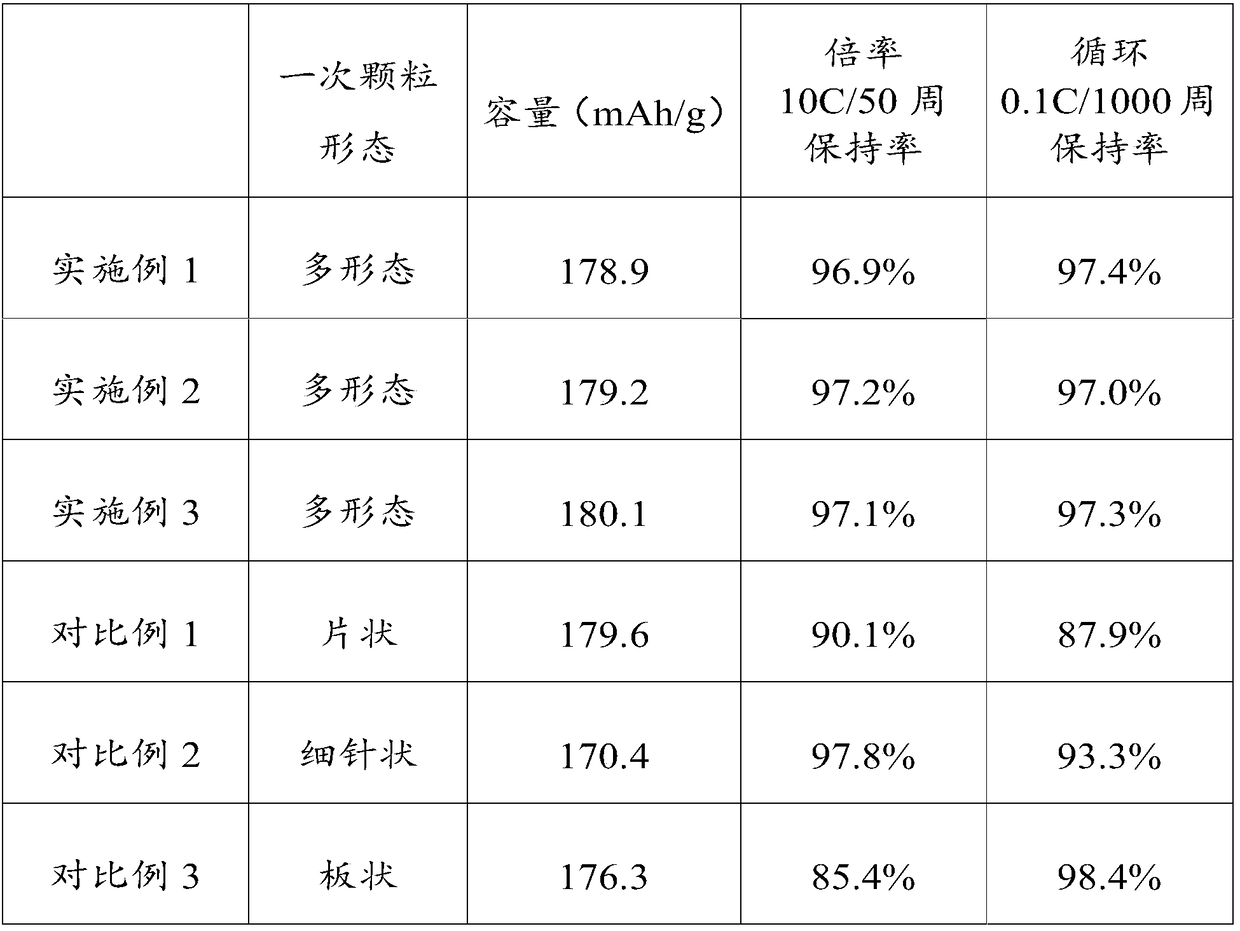

Examples

preparation example Construction

[0017] The embodiment of the present invention provides a method for preparing a ternary precursor in polycrystalline form, which includes:

[0018] Pass the metal salt solution containing nickel ion, cobalt ion and manganese ion together with liquid caustic soda solution and ammonia solution into the reaction kettle for mixed reaction;

[0019] Wherein, the reaction kettle has a plurality of liquid inlet pipes for introducing the metal salt solution, and the flow rates of the metal salt solutions through the plurality of liquid inlet pipes are different.

[0020] In the prior art, the precursor of the positive electrode material of the ternary battery is usually a powdery spherical particle with a D50 of 2-25 μm, which is called a secondary particle in the industry. The secondary particle is formed by the accumulation of several nano-scale primary particles. The length of the primary particle is 10-1000nm. Flake, rod, flower, etc. Different primary particle shapes show a cl...

Embodiment 1

[0033] The embodiment of the present invention provides a ternary precursor in polycrystalline form, and its preparation method includes:

[0034] S1. Dissolving nickel nitrate, cobalt nitrate and manganese nitrate in pure water according to the metal molar ratio of 92:6:2 and mixing to obtain a metal salt solution. Wherein, the metal ion concentration of the metal salt solution is 80 g / L.

[0035] Dissolve aluminum nitrate, magnesium nitrate and zirconium nitrate in water to make doping ion solution. Wherein, the concentration of doped metal ions is 0.5 g / L.

[0036] Prepare a 10% ammonia solution.

[0037] Prepare a 35% sodium hydroxide solution.

[0038] S2. In clean 10m 3 The above-mentioned ammonia solution, sodium hydroxide solution and pure water are quantitatively added into the reactor through the automatic PLC control system as the bottom liquid, and the final liquid level reaches the overflow port. The ammonia concentration is controlled at 15±0.5g / L, and the pH i...

Embodiment 2

[0042] The embodiment of the present invention provides a ternary precursor in polycrystalline form, and its preparation method includes:

[0043] S1. Dissolving nickel chloride, cobalt sulfate and manganese sulfate in pure water according to the metal molar ratio of 90:6:4 and mixing to obtain a metal salt solution. Wherein, the metal ion concentration of the metal salt solution is 100 g / L.

[0044] Dissolve aluminum nitrate, magnesium nitrate and titanium chloride in water to make doping ion solution. Wherein, the concentration of doped metal ions is 50 g / L.

[0045] Prepare a 30% ammonia solution.

[0046] Prepare a potassium hydroxide solution with a concentration of 21%.

[0047] S2. In clean 10m 3 The above-mentioned ammonia solution, sodium hydroxide solution and pure water are quantitatively added into the reactor through the automatic PLC control system as the bottom liquid, and the final liquid level reaches the overflow port. The ammonia concentration is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com