Highly flame-retardant and highly wear-resistant plastic particle and preparation method thereof

A technology of plastic particles and high flame retardancy, which is applied in the field of plastic particles, can solve the problems of reduced mechanical properties and wear resistance of plastic particles, hidden dangers of product surface pollution and environmental protection, poor flame retardant effect of flame retardants, etc., to achieve excellent toughness, High reactivity and binding capacity, stable and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

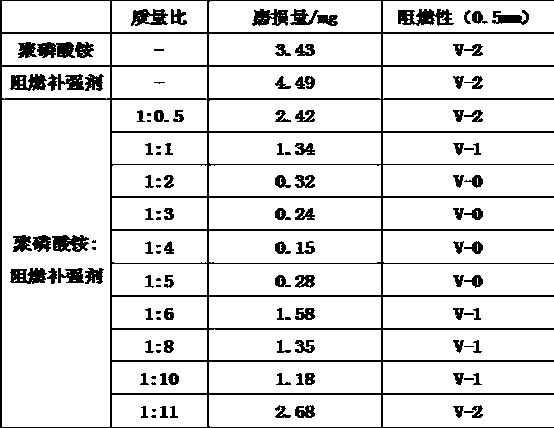

[0024] A high flame-retardant and high-abrasion-resistant plastic particle proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of nylon, 30 parts of polyether ether ketone, 18 parts of polyphenylenepyridyldiimidazole fiber, 1 part of ammonium polyphosphate, 2 parts of flame retardant reinforcing agent, 3 parts of butyl octadecenoate, 1 part of silane coupling agent, 1 part of antioxidant;

[0025] The silane coupling agent is a compounding agent of isobutyltriethoxysilane and polymethyltriethoxysilane with a mass ratio of 1:3;

[0026] Described flame retardant reinforcing agent is made by following method:

[0027] S1. Prepare raw materials according to the weight parts: 8 parts of tin dioxide, 30 parts of 30% sodium hydroxide solution, 20 parts of hydrogen peroxide, 1 part of isooctyl palmitate, 5 parts of fluorinated silicon oil, and 2 parts of cobalt powder;

[0028] S2. Add 30% sodium hydroxide solution into the reaction k...

Embodiment 2

[0036] A high flame-retardant and high-abrasion-resistant plastic particle proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of nylon, 35 parts of polyether ether ketone, 22 parts of polyphenylene pyridodiimidazole fiber, 1.5 parts of ammonium polyphosphate, 6 parts of flame retardant reinforcing agent, 5 parts of butyl octadecenoate, 2 parts of silane coupling agent, 2 parts of antioxidant;

[0037] The silane coupling agent is a compounding agent of isobutyltriethoxysilane and polymethyltriethoxysilane with a mass ratio of 1:1;

[0038] Described flame retardant reinforcing agent is made by following method:

[0039] S1, prepare raw materials according to the weight parts: 12 parts of tin dioxide, 35 parts of 30% sodium hydroxide solution, 30 parts of hydrogen peroxide, 2 parts of isooctyl palmitate, 8 parts of fluorinated silicon oil, 3.5 parts of cobalt powder;

[0040] S2. Add 30% sodium hydroxide solution into the react...

Embodiment 3

[0048] A high flame-retardant and high-abrasion-resistant plastic particle proposed by the present invention comprises the following raw materials in parts by weight: 70 parts of nylon, 40 parts of polyether ether ketone, 25 parts of polyphenylenepyridimidazole fiber, 2 parts of ammonium polyphosphate, 10 parts of flame retardant reinforcing agent, 8 parts of butyl octadecenoate, 3 parts of silane coupling agent, 3 parts of antioxidant;

[0049] The silane coupling agent is a compounding agent of isobutyltriethoxysilane and polymethyltriethoxysilane with a mass ratio of 3:1;

[0050] Described flame retardant reinforcing agent is made by following method:

[0051] S1. Prepare raw materials according to the weight parts: 15 parts of tin dioxide, 40 parts of 30% sodium hydroxide solution, 40 parts of hydrogen peroxide, 3 parts of isooctyl palmitate, 10 parts of fluorinated silicon oil, and 5 parts of cobalt powder;

[0052] S2. Add 30% sodium hydroxide solution into the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear coefficient | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com