Nitrogen-doped super-stable porous polymer composite material and preparation method thereof

A technology of porous polymer and composite material, which is applied in the field of nitrogen-doped ultra-stable porous polymer composite material and its preparation, can solve problems such as poor electrical conductivity, and achieve improved surface wettability, excellent performance, and excellent electrochemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

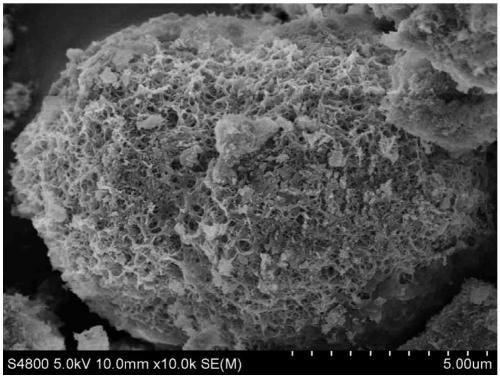

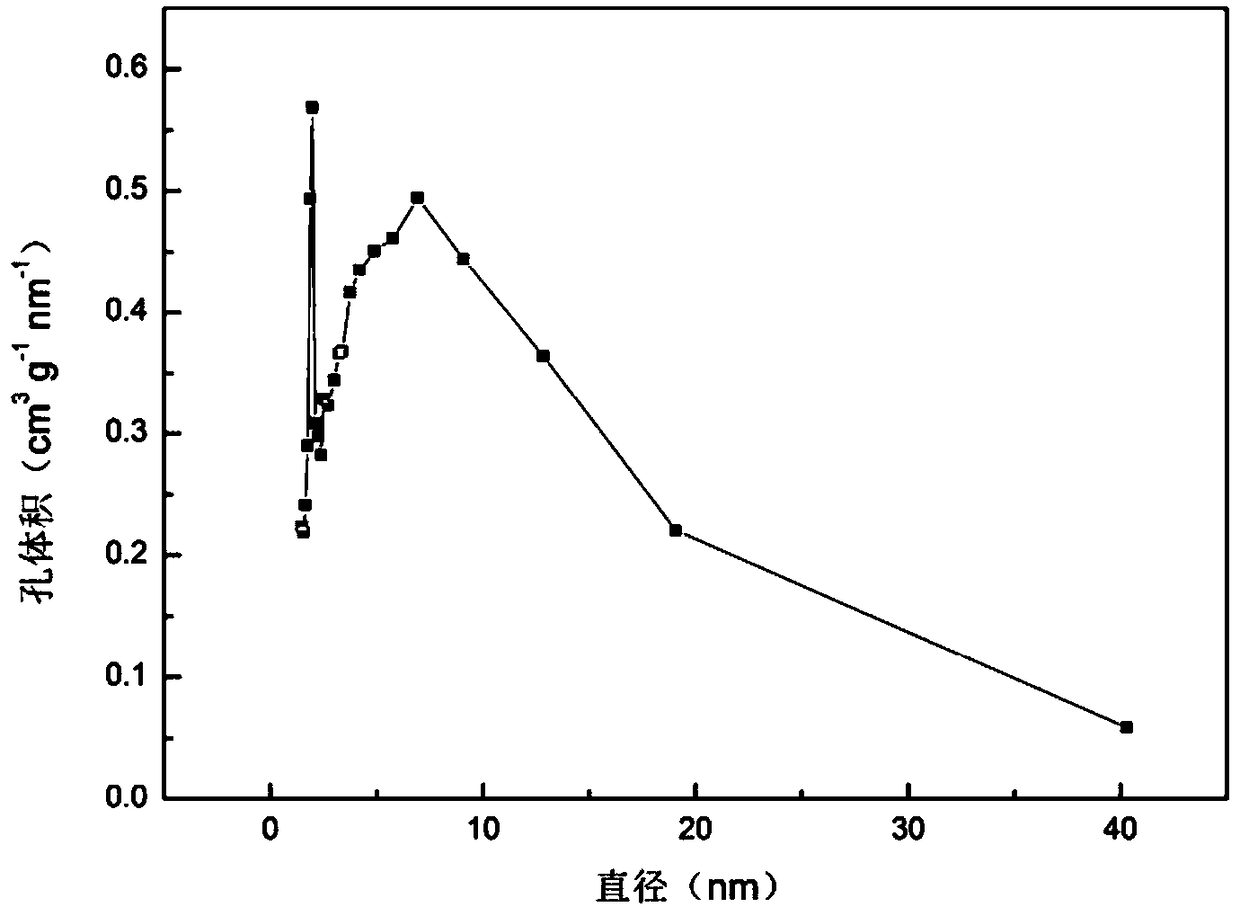

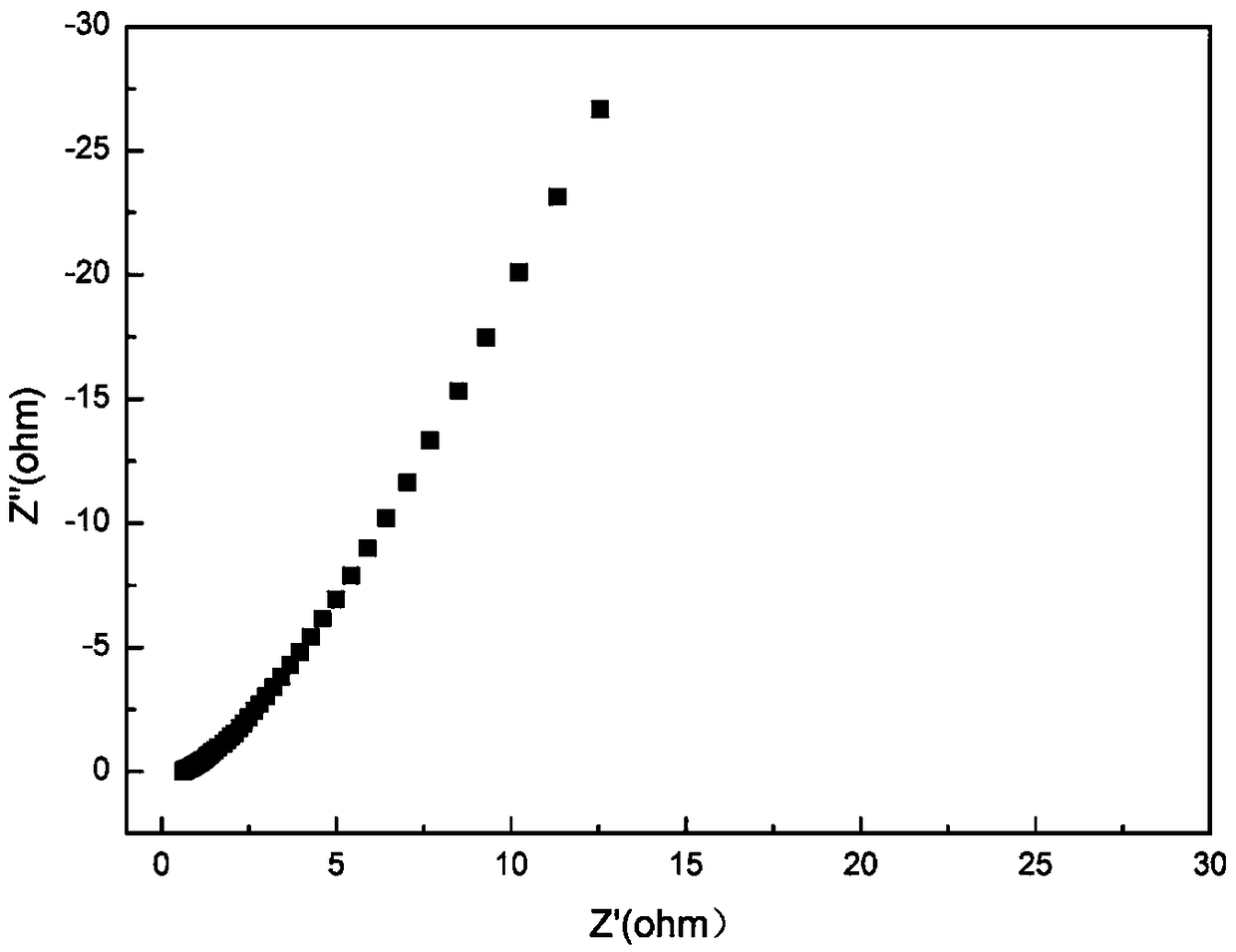

Embodiment 1

[0025] First prepare the organic ligand, weigh 0.6306g melamine and 2.2501g p-aldehyde benzoic acid and react in 40ml o-xylene at 150°C for 10h. The white product was obtained by suction filtration and purified with water and ethanol 1:1. Vacuum-dried at 80°C for 8 hours, ready for use. Then take 0.2613g organic ligand and 0.2910 cobalt nitrate hexahydrate into the reaction kettle, the solvent is DMF:EtOH=2:1, respectively react at 80°C for 60h, then naturally cool and filter to obtain the product, and dry it at 80°C to obtain Co-PCPs-80 material. Electrochemical performance tests were performed on it, and the charge transfer resistance (Rct) of the composite material was 0.5737Ω., and it had a low equivalent series resistance value and excellent diffusion properties. The cyclic voltammetry curves are rectangular-like with weaker redox peaks, indicating the fast charge propagation capability of both electric double layer capacitance and pseudocapacitance. Calculated from th...

Embodiment 2

[0027] First prepare the organic ligand, weigh 0.6306g melamine and 2.2501g p-aldehyde benzoic acid and react in 40ml o-xylene at 150°C for 9h. The white product was obtained by suction filtration and purified with water and ethanol 1:1. Vacuum-dried at 80°C for 8 hours, ready for use. Then take 0.2613g of organic ligand and 0.2910g of cobalt nitrate hexahydrate into the reaction kettle, the solvent is DMF:EtOH=2:1, respectively react at 100°C for 60h, then naturally cool and filter to obtain the product, and dry it at 80°C to obtain Co-PCPs-100 material. Electrochemical performance tests were carried out on it. The charge transfer resistance (Rct) of the composite material was 0.6319Ω., and it had a low equivalent series resistance value and excellent diffusion performance. The cyclic voltammetry curves are rectangular-like with weaker redox peaks, indicating the fast charge propagation capability of both electric double layer capacitance and pseudocapacitance. Calculated ...

Embodiment 3

[0029] First prepare the organic ligand, weigh 0.6306g melamine and 2.2501g p-aldehyde benzoic acid and react in 50ml o-xylene at 155°C for 10h. The white product was obtained by suction filtration and purified with water and ethanol 1:1. Vacuum-dried at 80°C for 8 hours, ready for use. Then take 0.2613g organic ligand and 0.2910 cobalt nitrate hexahydrate into the reaction kettle, the solvent is DMF:EtOH=1:1, respectively react at 120°C for 50h, then naturally cool and filter to obtain the product, and dry it at 80°C to obtain Co-PCPs-120 material. The electrochemical performance test shows that the charge transfer resistance (Rct) of the composite material is 0.562Ω., and has a low equivalent series resistance value and excellent diffusion performance. The cyclic voltammetry curves are rectangular-like with weaker redox peaks, indicating the fast charge propagation capability of both electric double layer capacitance and pseudocapacitance. Calculated from the charge-disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com