Heavy metallic mineral thermosetting resin coated sand, preparation method and application thereof

A technology of resin coating and mineralization, which is applied in chemical instruments and methods, earthwork drilling, and drilling compositions, etc., can solve problems such as casing corrosion, affecting casing strength, and shortening the effective period of sand control. The effect of good temperature and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

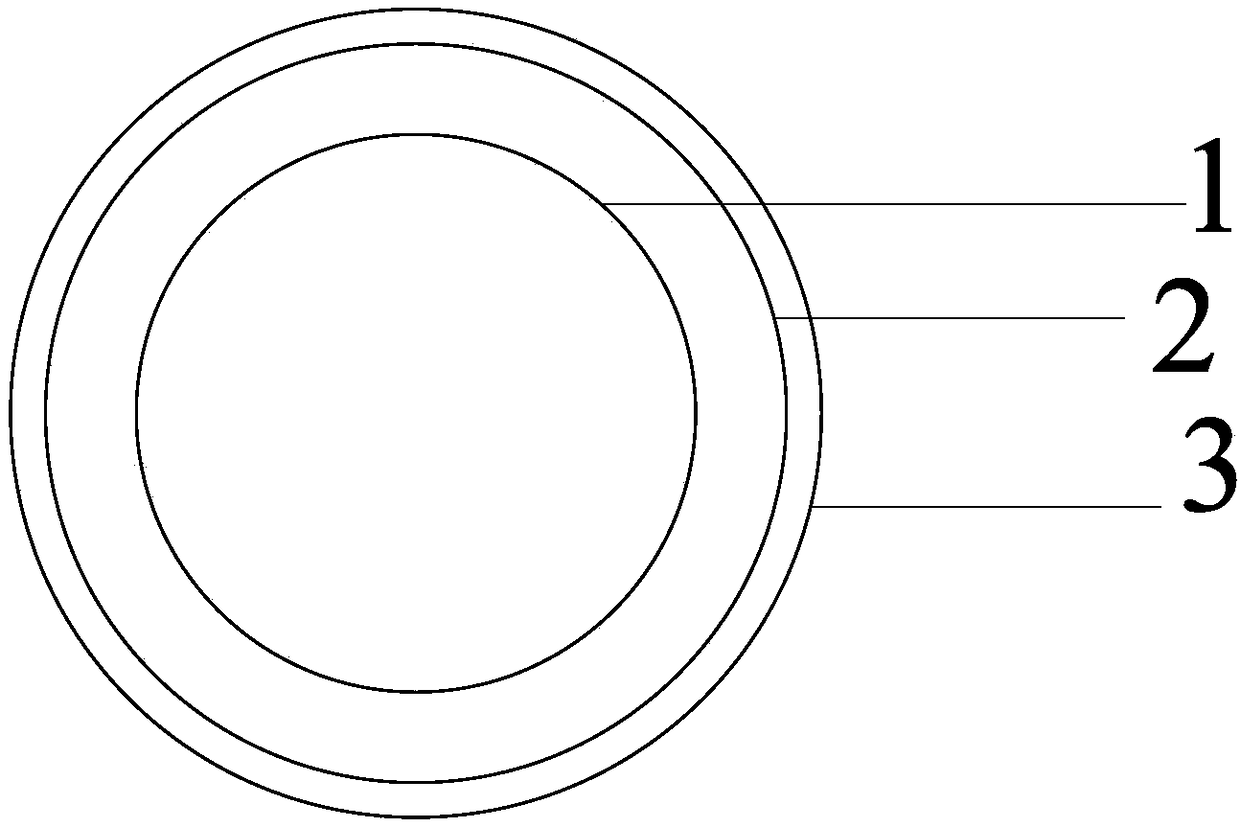

[0082] This embodiment provides a kind of heavy metal mineralization thermosetting resin coated sand, which is prepared by the following steps:

[0083] 1. Preparation of heavy metal mineralization particles

[0084] After crushing the raw material of heavy metal mineralization, sieve the raw material of 30 meshes; then dry it at 150°C for 5 hours; when drying, pass air into the oven to remove dust, control the content of fine powder below 0.3wt%, and obtain heavy metal mineralization particles. A slag rich in copper oxide and silicon carbide;

[0085] Wherein, the slag is slag resistant to steam corrosion, and the slag is black particles with a particle size range of 0.4-1.25mm and a bulk density of 1.50-1.75g / cm 3 , sphericity ≥ 0.5, roundness ≥ 0.5, alkali solubility ≤ 5%;

[0086] Based on the total weight of the slag as 100%, the content of the copper oxide is 50-60wt%, and the content of the silicon carbide is 20-30wt%;

[0087] 2. Preparation of thermosetting resin ...

Embodiment 2

[0100] This embodiment provides a kind of heavy metal mineralization thermosetting resin coated sand, which is prepared by the following steps:

[0101] 1. Preparation of heavy metal mineralization particles

[0102] After crushing the raw material of heavy metal mineralization, sieve the raw material of 30 meshes; then dry it at 150°C for 5 hours; when drying, pass air into the oven to remove dust, control the content of fine powder below 0.3wt%, and obtain heavy metal mineralization particles. A slag rich in copper oxide and silicon carbide;

[0103] Wherein, the slag is slag resistant to steam corrosion, and the slag is black particles with a particle size range of 0.4-1.25mm and a bulk density of 1.50-1.75g / cm 3 , sphericity ≥ 0.5, roundness ≥ 0.5, alkali solubility ≤ 5%;

[0104] Based on the total weight of the slag as 100%, the content of the copper oxide is 50-60wt%, and the content of the silicon carbide is 20-30wt%;

[0105] 2. Preparation of thermosetting resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap