Method for preparing ethanol by using tobacco stems as biorefinery raw materials

A biorefining and raw material technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, biofuels, etc., can solve the problems of low biotransformation efficiency and achieve high-efficiency biorefinery, cost saving, and production cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

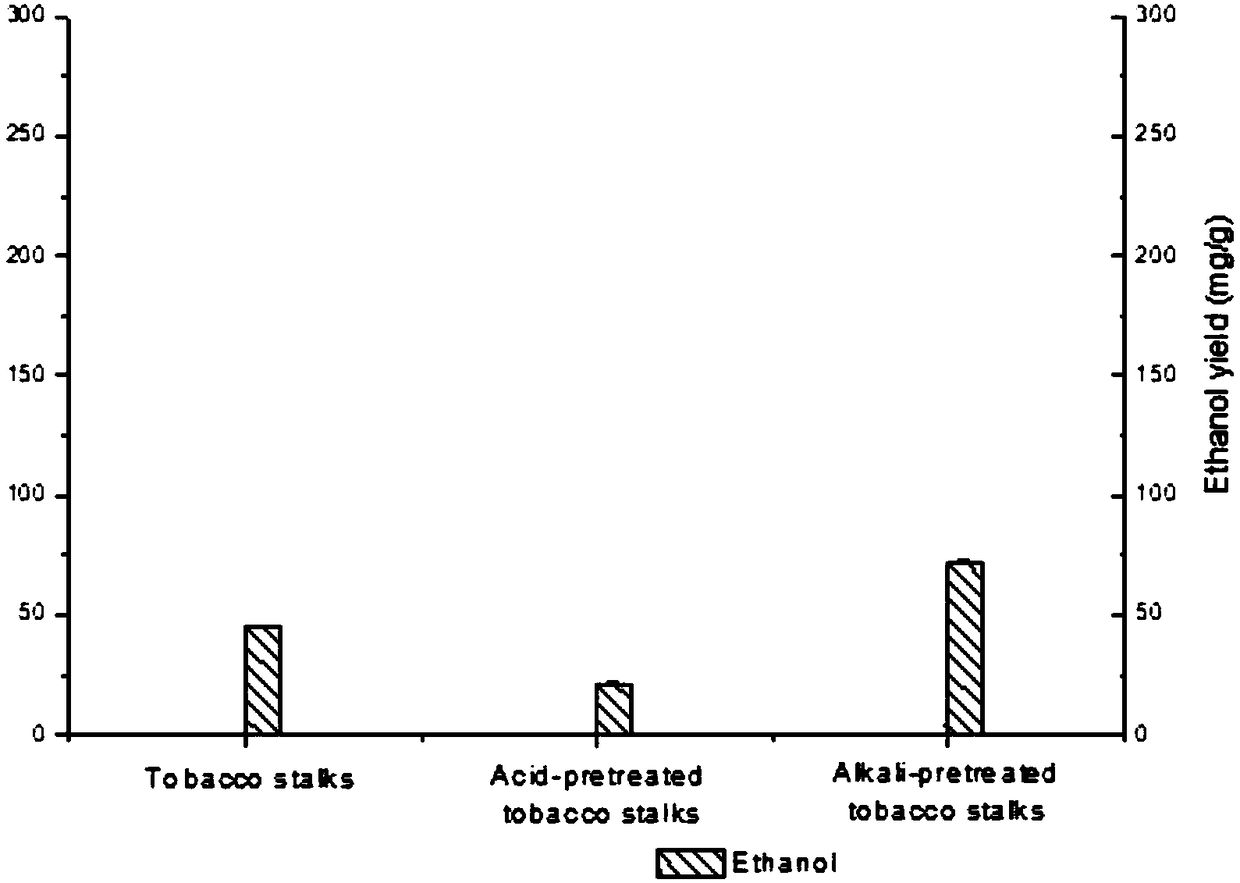

Problems solved by technology

Method used

Image

Examples

Embodiment 1

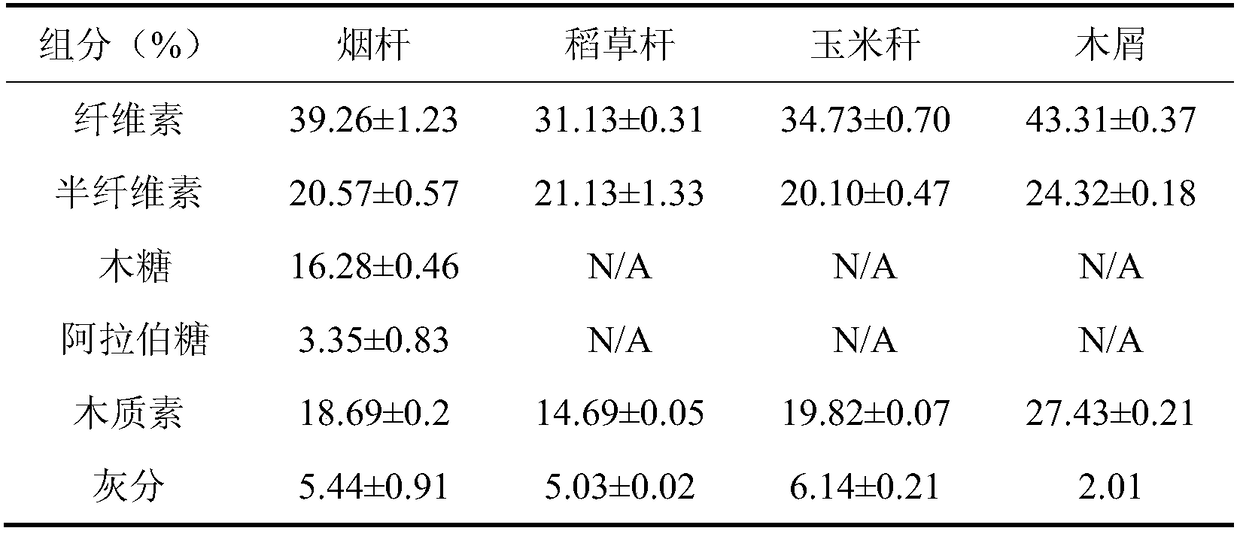

[0029] A method for producing reducing sugar by biorefining of tobacco rods described in Example 1 is characterized in that the specific steps are as follows:

[0030] (1) Pretreatment of tobacco rod raw materials:

[0031] a. Take fresh tobacco rods and wash off the floating dust and impurities on the surface with natural water. After 10 days of natural drying outdoors, bake them in an oven at 50°C for 2 days, then take them out and cool them to room temperature, and grind them with a pulverizer. Chopped into small pieces of 0.5-5cm in length, put them into a 5L reactor, and add NaOH solution with a concentration of 4% according to the ratio of solid-to-liquid ratio of 1:5;

[0032] b. Soak the solid-liquid mixture in step (1) at a constant temperature of 40-75°C for 3 hours, then heat it to 80°C for pretreatment for 70 minutes, and transfer the heat-treated solid-liquid mixture to a suction filter for suction filtration After the suction filtration is completed, add distill...

Embodiment 2

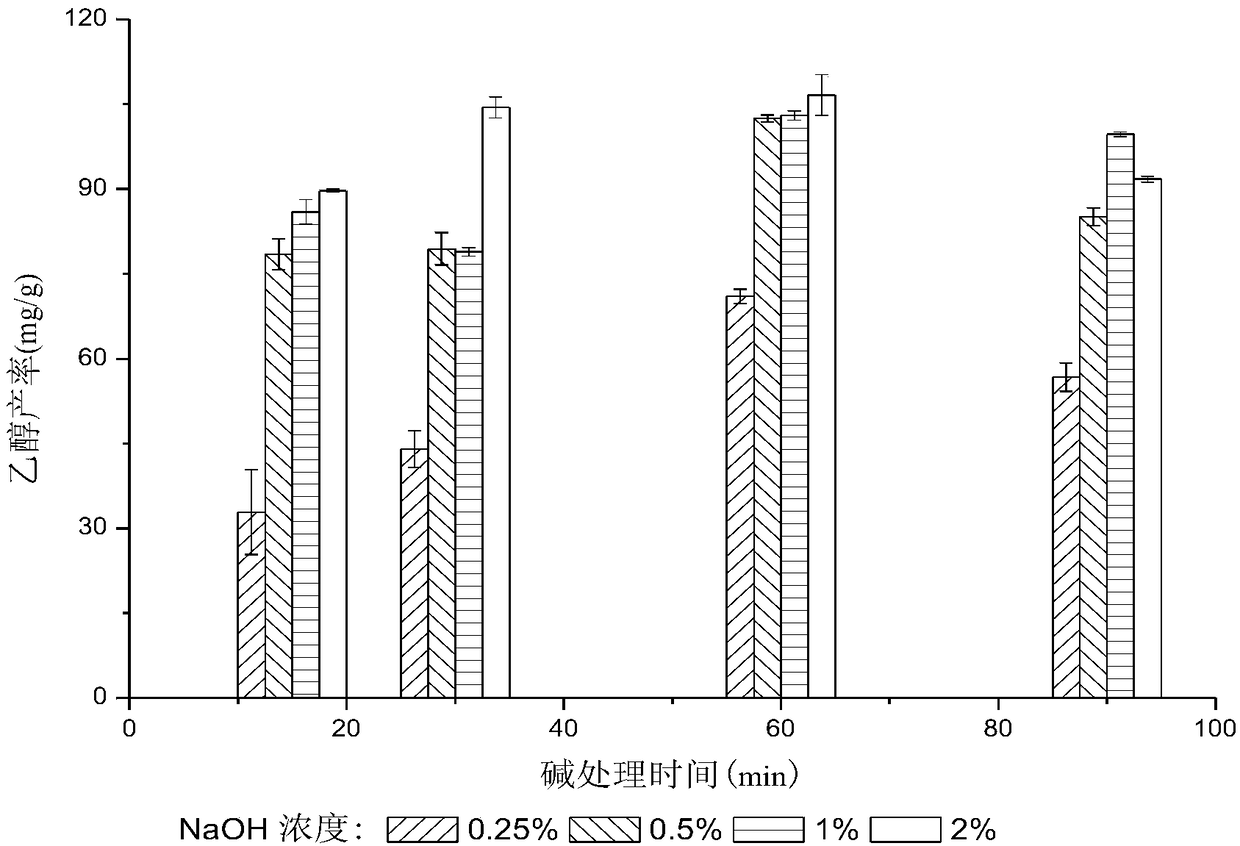

[0036] Embodiment 2: a kind of pretreatment method that improves tobacco rod biotransformation efficiency, is characterized in that concrete steps are as follows:

[0037] (1) Pretreatment of tobacco rod raw materials:

[0038] a. Take fresh tobacco rods and wash off the floating dust and impurities on the surface with natural water. After 20 days of natural drying outdoors, bake them in an oven at 55°C for 2 days, then take them out and cool them to room temperature, and grind them with a pulverizer. Chopped into 0.5-5cm long pieces and put them into a 10L reactor, add 2% NaOH solution according to the solid-to-liquid ratio of 1:10;

[0039] b. Treat the solid-liquid mixture in step (1) in a water bath at 90°C for 60 minutes, wash with water and filter until neutral, collect the treated fibrous residue and dry it at 50-60°C to obtain the pretreated Tobacco rod raw material B.

[0040] (2) Add 10 g of Saccharomyces cerevisiae dry powder preparation into 120 mL of 3% glucose ...

Embodiment 3

[0043] Embodiment 3: a kind of pretreatment method that improves tobacco rod biotransformation efficiency, is characterized in that concrete steps are as follows:

[0044] (1) Pretreatment of tobacco rod raw materials:

[0045] a. First clean the fresh tobacco rods with natural water to remove the floating dust and impurities on the surface, and then dry them outdoors for 30 days, then bake them in an oven at 60°C for 1 day, then take them out and cool them to room temperature, and use a grinder to grind them It is chopped into small pieces with a length of 0.5 to 5 cm and put into an 8L reactor, and a NaOH solution with a concentration of 0.5% is added according to the ratio of solid to liquid ratio of 1:20;

[0046] b. Soak the solid-liquid mixture in step (1) at a constant temperature of 40°C for 0.5 hours, heat it to 90°C in a water bath for 60 minutes, and transfer the heat-treated solid-liquid mixture to a suction filter for suction filtration After the suction filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com