Single-layer porous NiFe hydrotalcite-based electrocatalytic oxygen evolution electrode as well as preparation method and application thereof

A technology of oxygen evolution electrode and porous nickel, which is applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of high energy consumption, complicated process, unfriendly environment, etc., achieve improved catalytic activity, wide range of raw material sources, increase The effect of distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

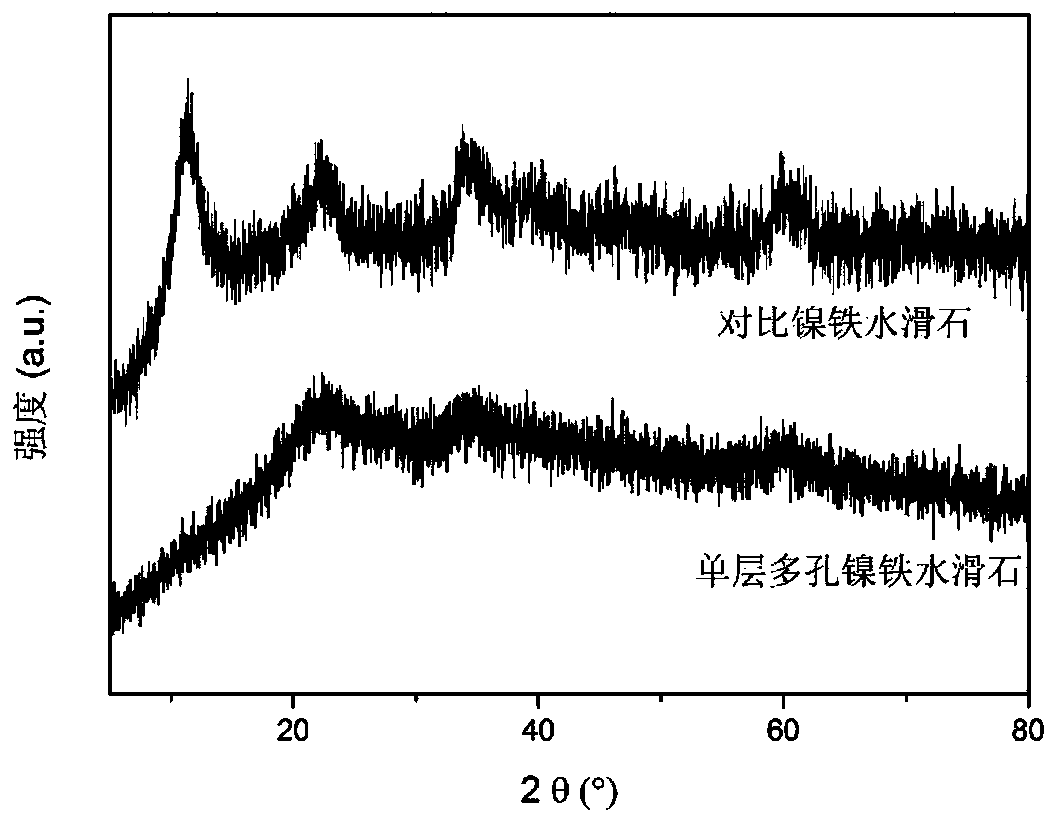

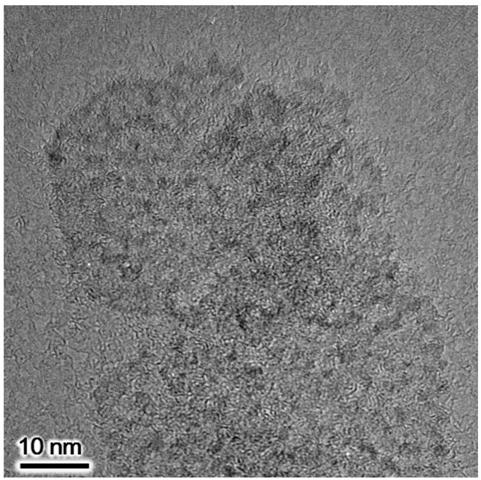

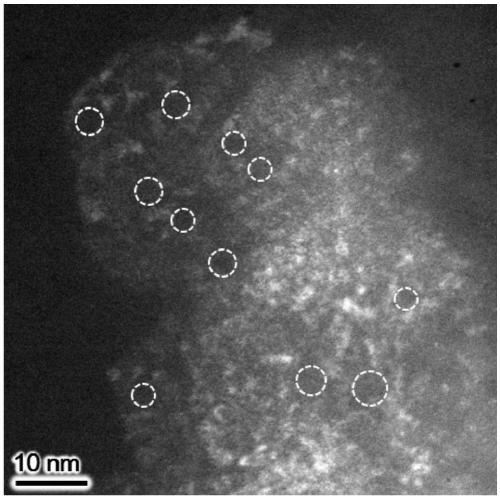

[0047] Preparation of single-layer porous nickel-iron hydrotalcite

[0048] 1) Prepare an aqueous formamide solution (volume fraction of formamide is 23%), and take 20 mL of the aqueous formamide solution. Add 2.5 mol / L NaOH aqueous solution dropwise into the formamide aqueous solution, adjust its pH value to 10, and heat the solution to 80°C.

[0049] 2) Add 20 mL of an aqueous solution containing 0.375 mol / L nickel nitrate and 0.125 mol / L ferric nitrate dropwise into the aqueous formamide solution in step 1). At the same time, 20 mL of 2.5 mol / L NaOH aqueous solution was added dropwise to keep the pH of the solution at 10. During the dropwise addition of nickel nitrate, ferric nitrate mixed aqueous solution and NaOH aqueous solution, floc products gradually appeared in the formamide aqueous solution.

[0050] 3) The floc product obtained in step 2) is centrifuged, and an aqueous solution is used for centrifugal cleaning, and after drying at 60° C. for 6 hours, it becomes a...

Embodiment 2

[0077] Different from Example 1, in the preparation process of the preparation of single-layer porous nickel-iron hydrotalcite, nickel nitrate and ferric nitrate are replaced by nickel chloride and ferric chloride respectively, and the nickel chloride solution and ferric chloride solution The concentrations are 0.375mol / L and 0.125mol / L respectively.

[0078] The single-layer porous nickel-iron hydrotalcite-based electrocatalytic oxygen evolution electrode prepared in this way, its electrocatalytic oxygen evolution performance test shows that the current density j reaches 10mA cm -2 , the required overpotential is 233mV, and the Tafel slope is 48mV dec -1 .

Embodiment 3

[0080] Different from Example 1, in the preparation process of the preparation of single-layer porous nickel-iron hydrotalcite, nickel nitrate and ferric nitrate are replaced by nickel chloride and ferric chloride respectively, and the nickel chloride solution and ferric chloride solution The concentrations are 0.75mol / L and 0.25mol / L respectively.

[0081] The single-layer porous nickel-iron hydrotalcite-based electrocatalytic oxygen evolution electrode prepared in this way, its electrocatalytic oxygen evolution performance test shows that the current density j reaches 10mA cm -2 When the overpotential is 241mV, the Tafel slope is 50mV dec -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com