Device and method for automatically detecting superheat degree and electrolysis temperature of aluminum electrolyte

A technology of aluminum electrolyte and aluminum electrolysis, which is applied in the direction of measuring devices, electric devices, thermometer parts, etc., can solve the problems that the measurement results cannot be entered into the control system in real time, the aluminum electrolysis control information is incomplete, and the manual input data lags, etc., to achieve Improve the level of intelligent control, improve labor productivity, and improve the effect of technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

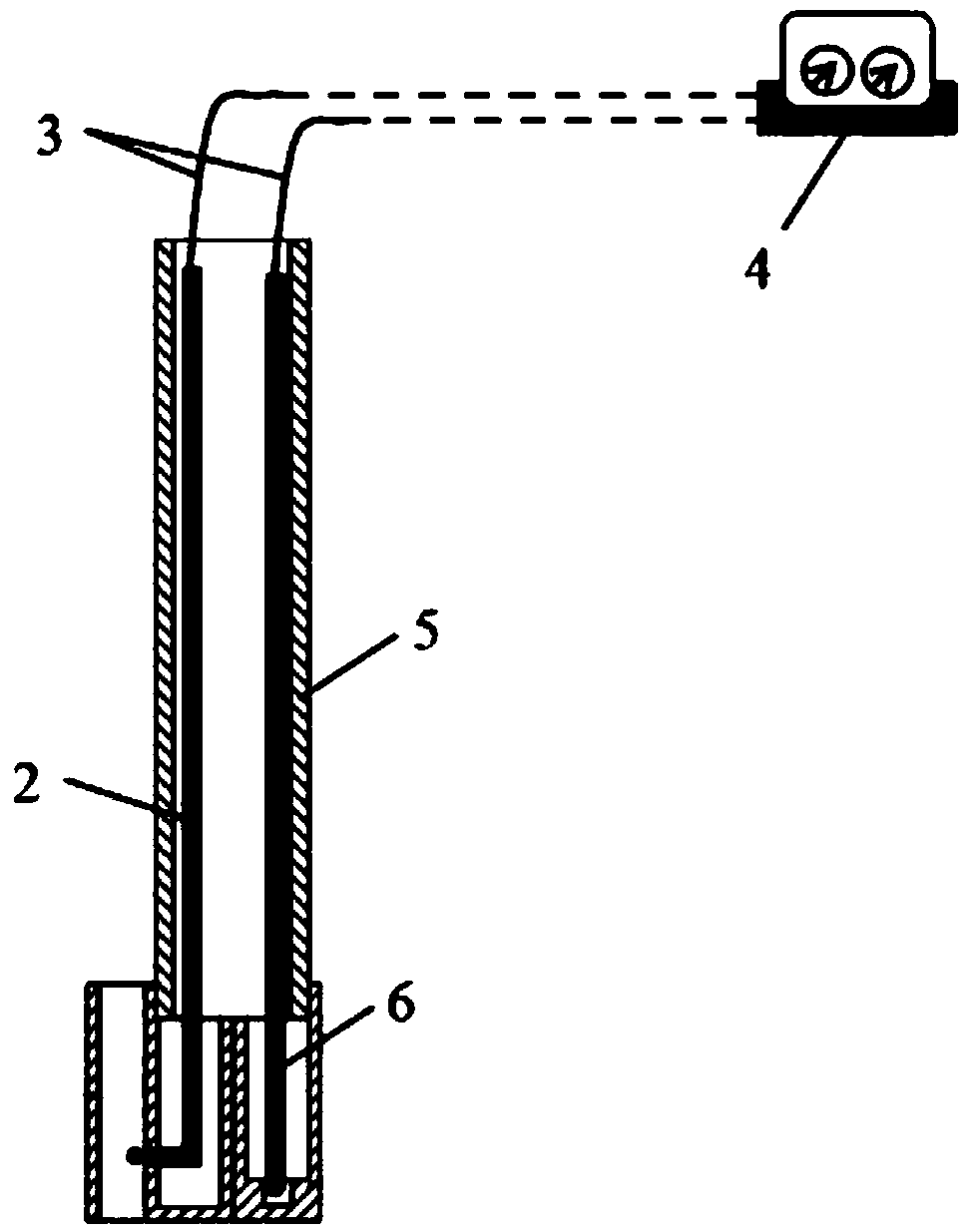

[0036] like figure 1 Shown is a schematic diagram of the device for automatically detecting the superheat of the aluminum electrolyte and the electrolysis temperature in the present invention, the device includes a first temperature sensor 2, a second temperature sensor 6, a data transmission system, a data analysis system 4 and an aluminum electrolysis multifunctional day car. The data transmission system includes a compensation line 3 . The aluminum electrolysis multifunctional crane is manually operated to drive the first temperature sensor 2 and the second temperature sensor 6 into and out of the aluminum electrolyte through a preset program.

[0037] The first temperature sensor 2 and the second temperature sensor 6 are fixed in the protective sleeve 5 and installed on the automatic lifting device of the aluminum electrolysis multi-function crane. The top ends of the first temperature sensor 2 and the second temperature sensor 6 are connected with a compensation wire 3 ...

Embodiment 2

[0047]In the test of a 300KA series electrolytic cell in an aluminum plant, the temperature of the electrolyte in the electrolytic cell was measured to be 942°C, the initial crystal temperature of the electrolyte was 933°C, and the degree of superheat was 9°C by using the device in Example 1 of the present invention. The measured electrolyte temperature is consistent with the electrolysis temperature displayed by the tank control box.

[0048] Part of the electrolyte was sampled from the electrolytic cell, and the primary crystal temperature of the electrolyte was measured by the step cooling curve method to be 933.4°C, that is, the superheat of the electrolytic cell was 8.6°C. The test results obtained by using the device for automatically detecting the superheat of the aluminum electrolyte and the electrolysis temperature are similar to those obtained by traditional experimental techniques, and the measurement error is within the error range of the galvanic couple.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com