Preparation method for Itraconazole composite particles

A technology of itraconazole and composite particles, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, and pharmaceutical formulas, can solve problems such as unfavorable production scale-up, and achieves favorable dispersion and safe formulation. Stable and effective, easy to produce and scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] prescription:

[0019] Material composition

Prescription ratio (%)

Itraconazole

35

50

polyethylene glycol 6000

15

[0020] Preparation:

[0021] 1) Preparation of mixed solution: Accurately weigh the mixture of 1.75g itraconazole, 2.50g hypromellose and 0.75g polyethylene glycol 6000 into a 500mL conical flask, add 200mL ethanol and dichloromethane Mix solvents (volume ratio 1:2) to dissolve completely;

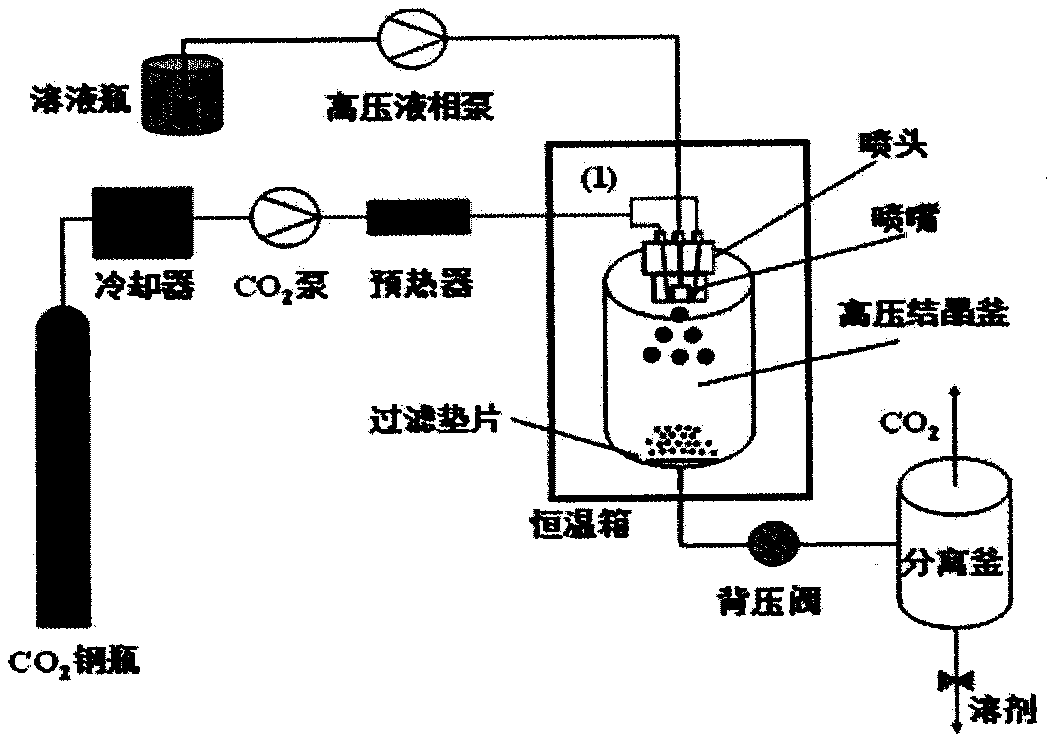

[0022] 2) CO2 feed: such as figure 1 As shown, open the valve of the CO2 cylinder, and the liquefied CO2 is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (60° from the middle solution channel) by the high-pressure pump, and the flow rate is controlled at 50mL / min;

[0023] 3) Control temperature and pressure: by regulating figure 1 The back pressure valve shown in t...

Embodiment 2

[0028] prescription:

[0029] Material composition

Prescription ratio (%)

Itraconazole

40

50

polyethylene glycol 6000

10

[0030] Preparation method: 1) Preparation of mixed solution: Accurately weigh the mixture of 1.6g itraconazole, 2.0g hypromellose and 0.4g polyethylene glycol 6000 into a 500mL conical flask, add 200mL ethanol and two A mixed solvent of methyl chloride (volume ratio 1: 1) to completely dissolve;

[0031] 2) CO 2 Feed: as figure 1 shown, open the CO 2 Cylinder valve, liquefied CO 2 The high-pressure pump is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (at 45° to the intermediate solution channel), and the flow rate is controlled at 75mL / min;

[0032] 3) Control temperature and pressure: by regulating figure 1 The back pressure valve shown controls the p...

Embodiment 3

[0037] prescription:

[0038] Material composition

Prescription ratio (%)

Itraconazole

40

hypromellose

40

polyethylene glycol 6000

20

[0039]Preparation method: 1) Preparation of mixed solution: Accurately weigh the mixture of 2.0g itraconazole, 2.0g hypromellose and 1.0g polyethylene glycol 6000 into a 500mL conical flask, add 200mL ethanol and two A mixed solvent of methyl chloride (volume ratio 1: 1) to completely dissolve;

[0040] 2) CO 2 Feed: as figure 1 shown, open the CO 2 Cylinder valve, liquefied CO 2 The high-pressure pump is continuously introduced into the high-pressure crystallization kettle of the supercritical fluid crystallization equipment system through the two symmetrical channels of the kettle head (60° to the intermediate solution channel), and the flow rate is controlled at 75mL / min;

[0041] 3) Control temperature and pressure: by regulating figure 1 The back pressure valve shown controls the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com