A kind of preparation technology of composite polymer diaphragm for lithium battery

A composite polymer and preparation process technology, which is applied in the field of preparation of composite polymer separators for lithium batteries, can solve the problems of uneven pore size distribution on the surface of composite membranes, high temperature melting damage, battery performance effects, etc. Uniform distribution of high temperature and strength, the effect of improving high temperature resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific preparation process of high-strength super-hydrophilic polyurethane is as follows:

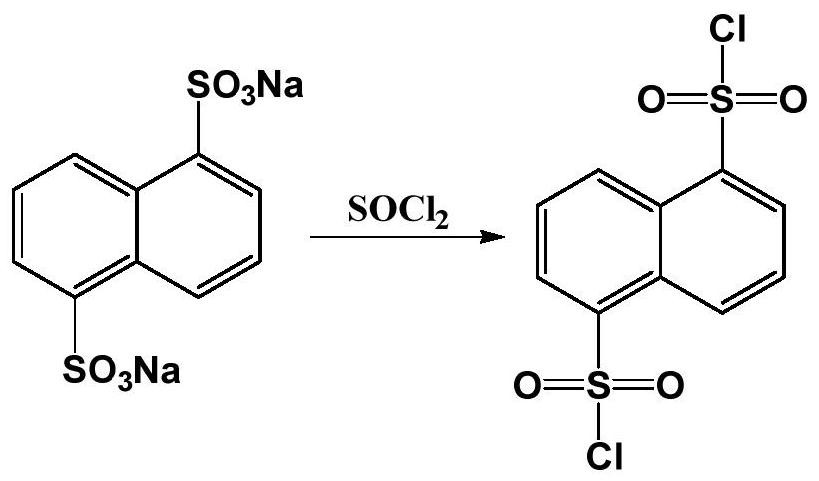

[0031] ① Weigh 1kg of 1,5-naphthalene disulfonate and dissolve it in 7L of water. When the temperature rises to 80°C, add 2.9kg of thionyl chloride to it, and after reflux reaction for 5 hours, keep the water phase after liquid separation, and carry out the water phase Evaporated and crystallized to obtain 1,5-naphthalene disulfonyl chloride;

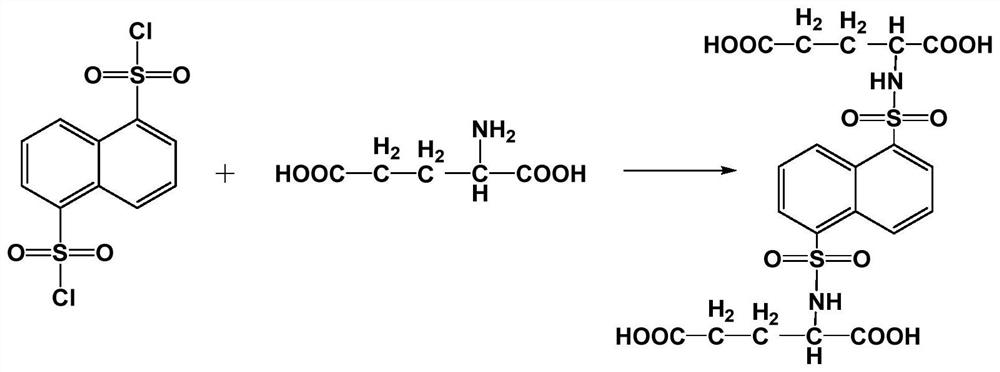

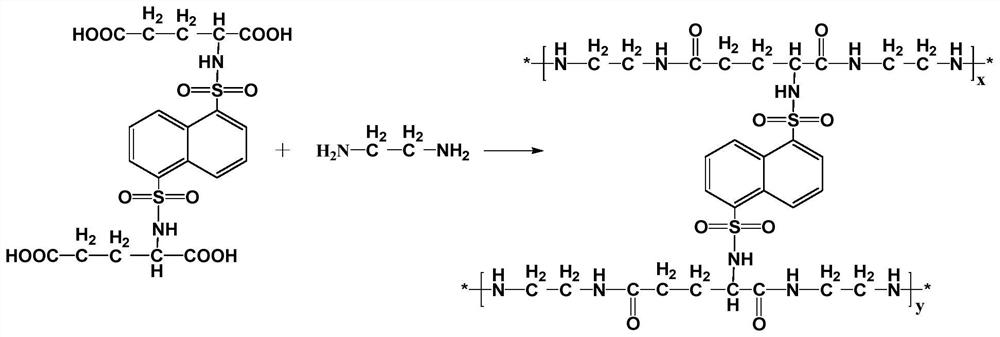

[0032] ②Weigh 1 kg of glutamic acid and dissolve it in 15L of dilute hydrochloric acid with a mass fraction of 1% to form a glutamic acid solution, add the prepared glutamic acid solution into the reaction vessel, raise the temperature to 70°C, and simultaneously add 0.73 kg of 1,5-naphthalene disulfonyl chloride prepared in step ①, reacted at constant temperature for 3 hours, then evaporated and crystallized, and at the same time washed the crystal with acetone solution, and then dried to obtain a cross-linked dicarboxylic polymer m...

Embodiment 2

[0036] The specific preparation process of high-strength super-hydrophilic polyurethane is as follows:

[0037] ① Weigh 1 kg of 1,5-naphthalene disulfonate and dissolve it in 8 L of water. When the temperature rises to 80 ° C, add 3 kg of thionyl chloride to it, and after reflux reaction for 5 hours, keep the water phase after liquid separation, and evaporate the water phase Crystallization to obtain 1,5-naphthalene disulfonyl chloride;

[0038] ②Weigh 1 kg of glutamic acid and dissolve it in 15L of dilute hydrochloric acid with a mass fraction of 1% to form a glutamic acid solution, add the prepared glutamic acid solution into the reaction vessel, raise the temperature to 70°C, and simultaneously add 0.75 kg of 1,5-naphthalene disulfonyl chloride prepared in step ①, reacted at constant temperature for 3 hours, then evaporated and crystallized, and at the same time washed the crystal with acetone solution, and then dried to obtain the cross-linked dicarboxylic polymer monomer;...

Embodiment 3

[0042] A preparation process for a composite polymer diaphragm for a lithium battery, comprising the following preparation process:

[0043] In the first step, the high-strength super-hydrophilic polyurethane prepared in Example 1 is added to the extruder and extruded after being melted at 150°C, then stretched to make it a parallel-arranged lamellar crystal structure, and then heat-treated and again Stretching separates the sheets to form narrow and long micropores, and finally heat-setting to obtain high-strength microporous polyurethane membranes;

[0044] In the second step, 0.215 kg of the surface aminated nano-ceramic powder prepared in Example 1 was dissolved in 1.505 L of water, and the ultrasonic dispersion was uniform, and then 100 g of the high-strength microporous polyurethane membrane prepared in the first step was soaked in water, and ultrasonically oscillated 30min, then drop 0.136kg of hexamethylene diisocyanate into it, and ultrasonicate while dropping, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com