High-thermal-conductivity boron nitride/natural rubber composite and preparation method thereof

A natural rubber and composite material technology, applied in the field of polymers, can solve the problems of harsh preparation conditions, complicated preparation process, and decreased elongation at break, and achieve improved dispersion performance, low dielectric constant, thermal conductivity, and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 2.8g of catechol and 1.6g of tetra(ethylenediyl)pentamine to 100ml of deionized water, adjust the pH of the aqueous solution to 8 with tris (Tris), then add 50g of nitrogen boron, at room temperature, the reaction was stirred at a stirring rate of 400r / min for 6h.

[0024] (2) Raise the temperature of the water bath to 70°C, add 0.5g of silane coupling agent KH560, stir at a stirring speed of 400r / min for 5h, wash with deionized water to neutral after the reaction stops, filter with suction, and dry in vacuum to obtain modification Boron nitride nanosheets.

[0025] (3) 100 parts by mass of natural rubber is plasticized at room temperature on an open mill, and 50 parts by mass of modified boron nitride nanosheets prepared by step (2) are gradually added to the natural rubber, and then 3 parts by mass of sulfur are gradually added, Knead with a knife and pack into triangles to make it evenly mixed.

[0026] (4) After kneading and parking for 24 hours, set a pre...

Embodiment 2

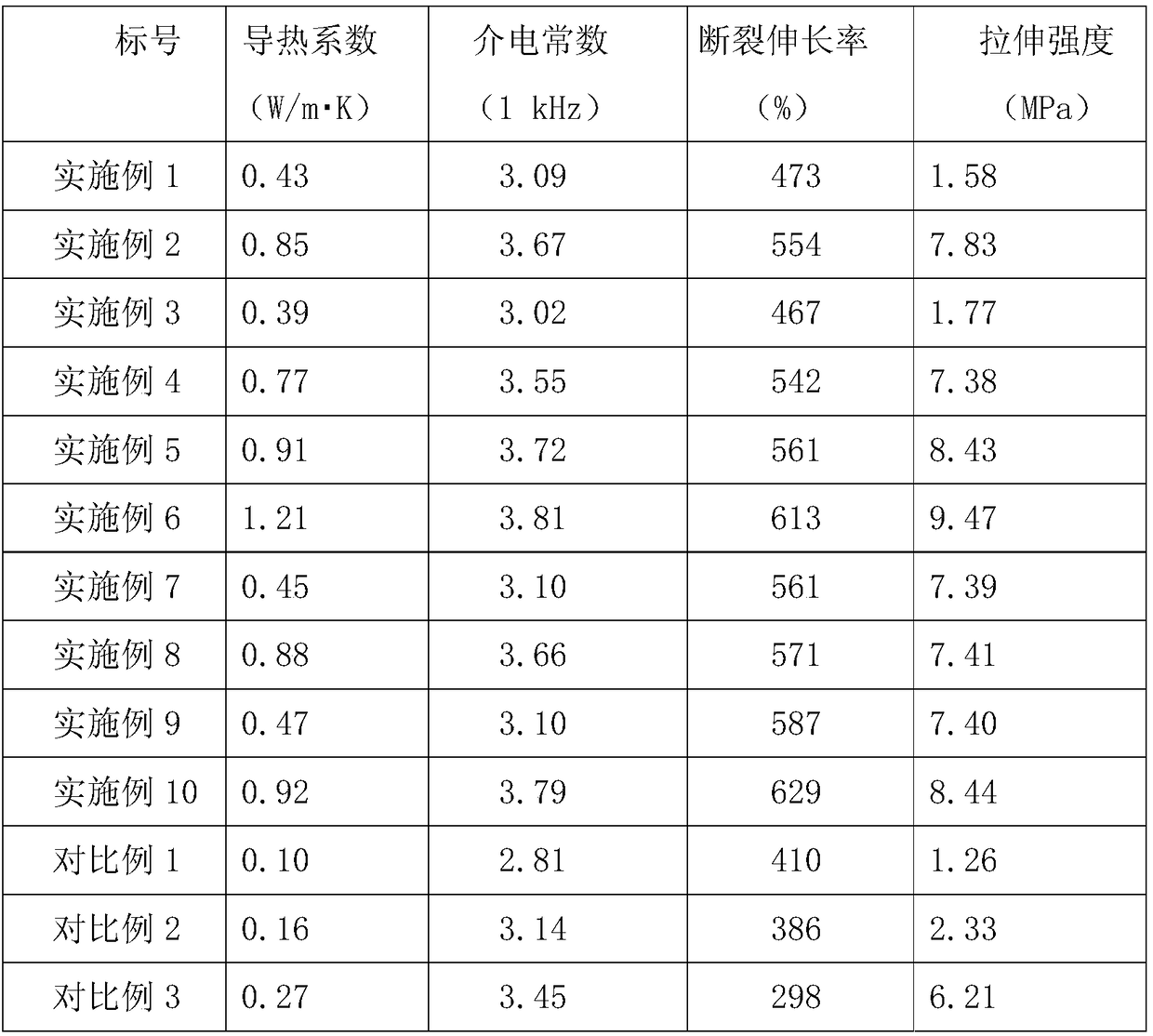

[0029] The preparation method is the same as in Example 1, except that the amount of modified boron nitride nanosheets is 200 parts by mass. The test results are shown in Table 1.

Embodiment 3

[0031] The preparation method is the same as in Example 1, except that the tetra(ethylenediyl)pentamine in the modifier is changed to pentaerythramine, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com