Manufacturing method of trench Schottky

A manufacturing method and trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulties in epitaxial layers, and achieve the effects of improving device performance, reducing resistance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

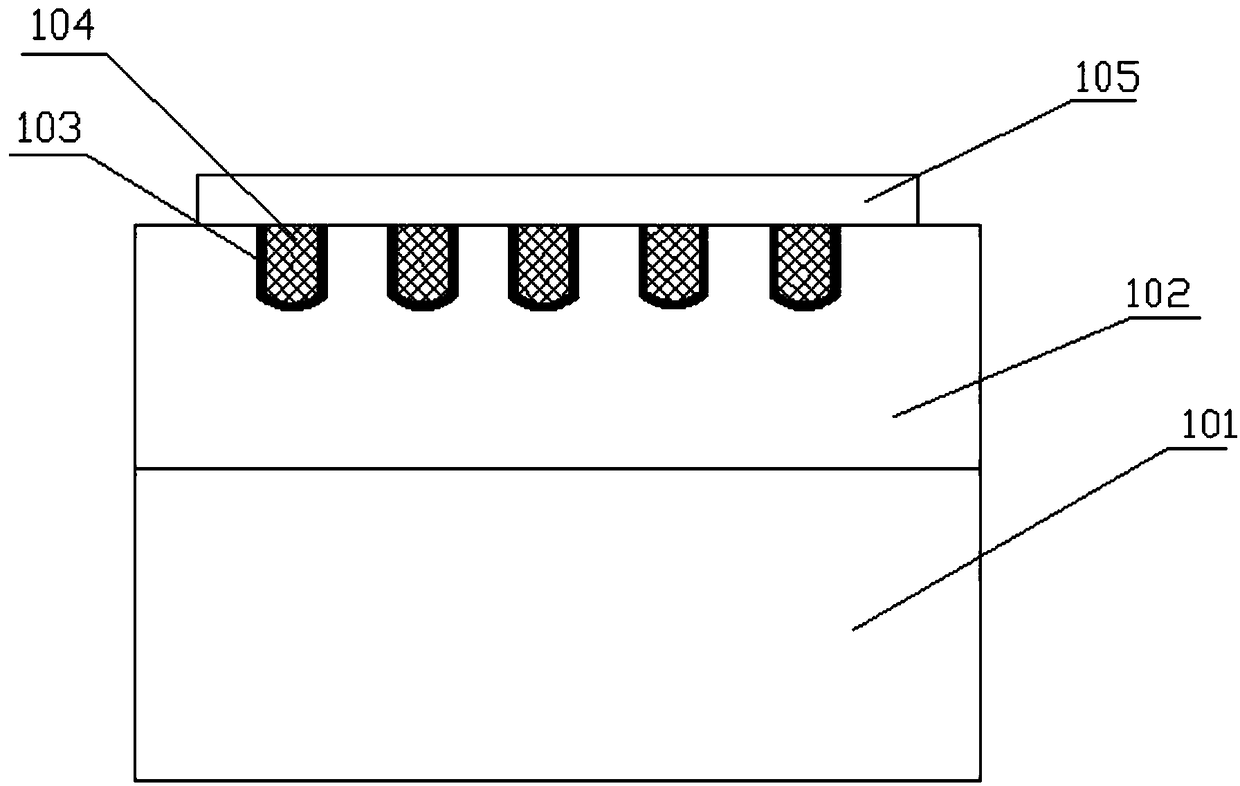

[0023] Step 1: First epitaxially layer a buffer layer on the N+ heavily doped silicon substrate, N: resistivity 0.1-20Ω.cm, thickness 1-20um, the epitaxial N of this layer mainly plays a role in ensuring the withstand voltage of the device The purpose of further reducing the forward voltage drop of the device and reducing the resistance of the drift region;

[0024] Step 2: Epitaxially layer a lightly doped layer on the buffer layer. Compared with the upper buffer layer, the doping concentration is reduced. N-: resistivity 0.3-30Ω.cm, thickness 1-20um, epitaxy N- is mainly effective Reduce the reverse leakage of the device, and optimize the withstand voltage between the barrier region and the trench by optimizing the resistivity of this layer. Both steps 1 and 2 are carried out at a temperature of 800-1150°C. The epitaxial buffer layer and the lightly doped layer are grown by the chemical vapor deposition process. The above-mentioned process is used to epitaxially buffer the l...

Embodiment 2

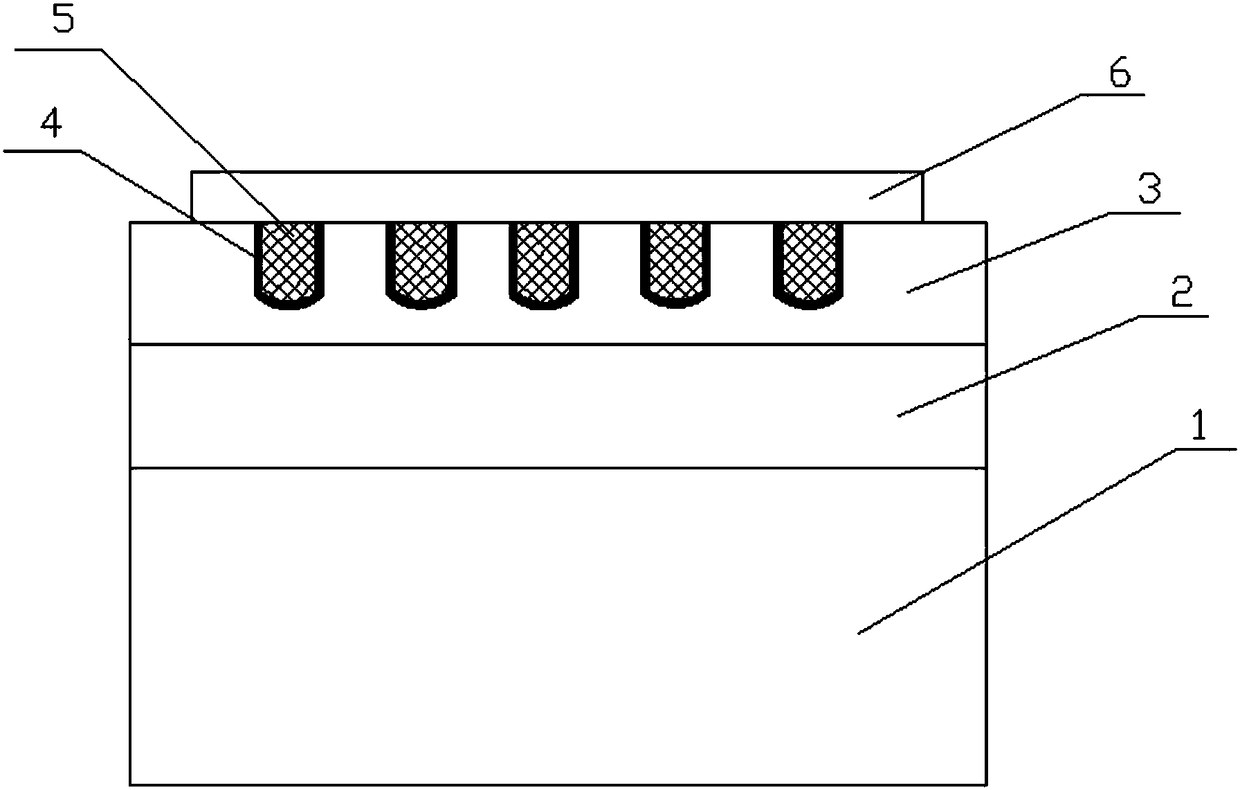

[0029] According to the different withstand voltage of the device, the number of epitaxial N-lightly doped layers in step 2 is not limited to one layer, but can be a multi-layer structure. Generally, the method of gradually reducing the doping concentration is adopted to gradually increase the resistivity of each epitaxial layer. That is, the doping concentration of each lightly doped layer gradually decreases from bottom to top, and the resistivity gradually increases accordingly. Of course, targeted optimization can also be carried out for individual layers.

[0030] Example 2 Change the epitaxial one lightly doped layer in Step 2 of Example 1 to epitaxially two lightly doped layers. The resistivity of the upper lightly doped layer is higher than that of the lower lightly doped layer, but the resistivity and thickness of each layer are still within the specified requirements. , N-: Resistivity 0.3~30Ω.cm, thickness 1~20um. Other steps are with embodiment 1.

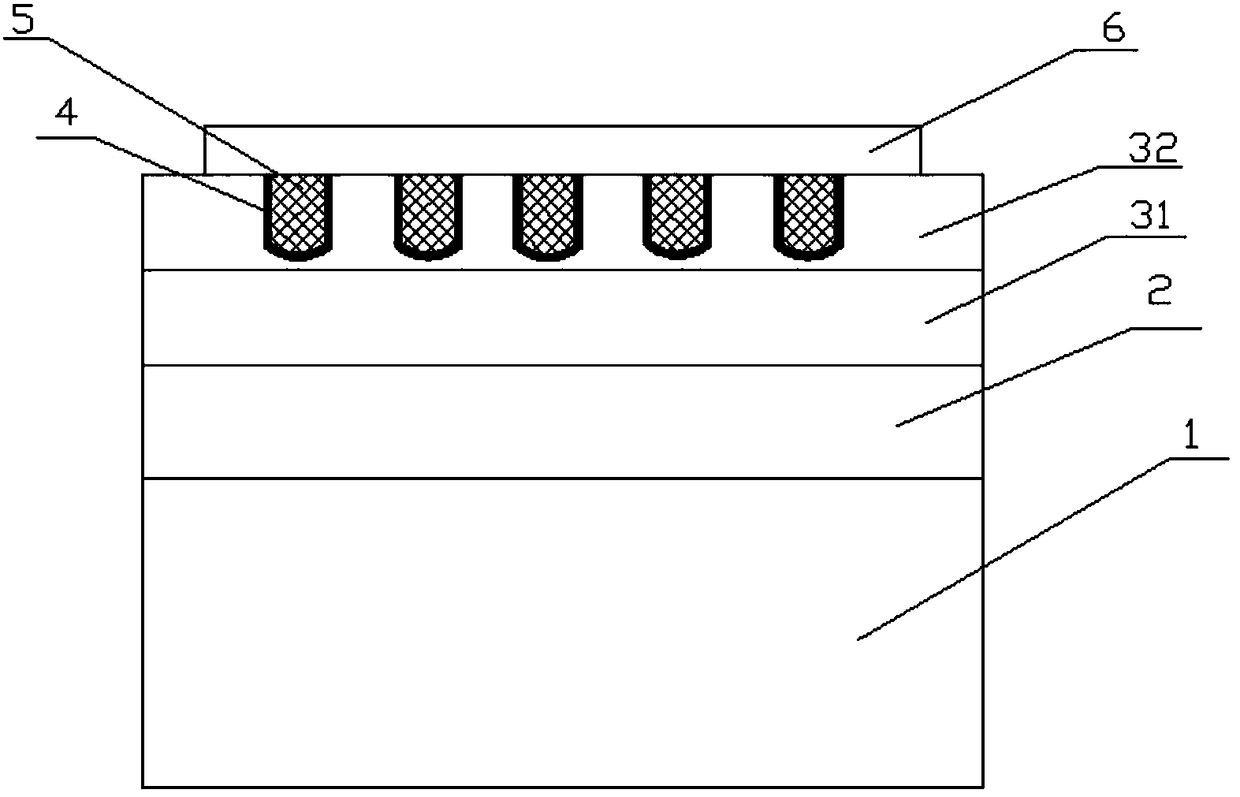

Embodiment 3

[0032] Example 3 Change the epitaxial one lightly doped layer in Step 2 of Example 1 to epitaxial four lightly doped layers. The resistivity of the four lightly doped layers gradually increases from bottom to top, but the resistivity and thickness of each layer are still specified Within the requirements, N-: resistivity 0.3~30Ω.cm, thickness 1~20um. Other steps are with embodiment 1.

[0033] In the present invention, a layer of buffer layer with a relatively higher doping concentration is first epitaxially used to further reduce the forward conduction voltage drop of the device and reduce the resistance of the drift region under the premise of ensuring the withstand voltage of the device, and then epitaxially epitaxially one or more layers The lightly doped layer with gradually reduced doping concentration makes the resistivity of each layer gradually increase, which can effectively reduce the reverse leakage of the device, realize the withstand voltage optimization between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com