Preparation method of slowly-digestible starch-based recombinant rice with low glycemic index

A slow-digesting starch and low glycemic index technology, applied in the field of food processing, can solve problems such as low glycemic index, and achieve the effects of low glycemic index, high content and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

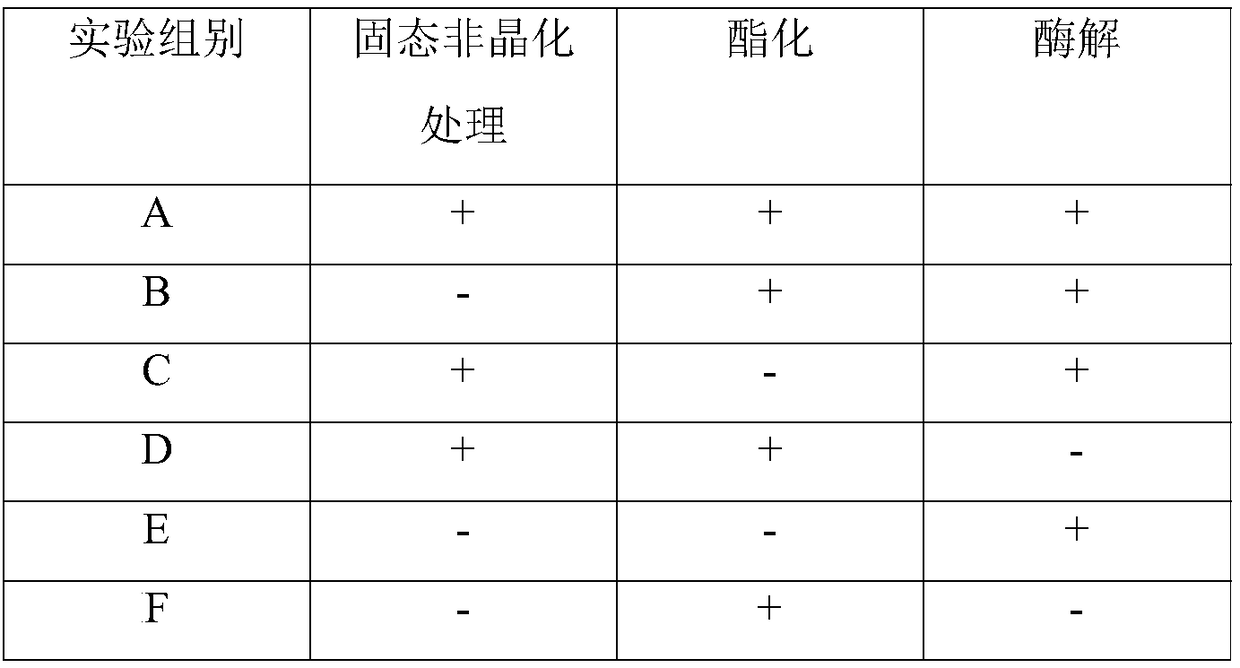

Embodiment 1

[0030] (1) Humidify the broken rice by spraying method. The spray temperature is 25°C, then take it out and spread it out, dry the surface moisture of the raw material with cold wind, and set it aside for use. The dry basis moisture content of the raw material after treatment is 30% to 40%.

[0031] (2) Use instantaneous high-temperature fluidization technology to carry out amorphization pretreatment on broken rice. After humidification treatment, it is transported into a high-temperature fluidization machine with a fluidization temperature of 220°C and a fluidization time of 30s. After treatment, it is discharged from the discharge port. Make the material gelatinization degree reach 65%.

[0032] (3) Then crush the treated broken rice into 80-mesh rice flour, add enzyme preparation and mix evenly. The enzyme preparation added by extrusion is selected from alkaline protease, and the total addition amount is 1% (w / w) of the raw material of rice flour, adjusted to a pH of 8.5, an...

Embodiment 2

[0037] (1) Use the spray method to humidify the broken rice. The spray temperature is 30°C, then take it out and spread it out, dry the surface moisture of the raw material with cold wind, and set it aside for use. The dry basis moisture content of the raw material after treatment is 30% to 40%.

[0038] (2) Next, use instantaneous high-temperature fluidization technology to carry out amorphization pretreatment on the broken rice. After the humidification treatment, it is transported into a high-temperature fluidization machine with a fluidization temperature of 250°C and a fluidization time of 50s. After treatment, it is discharged from the discharge port. , so that the gelatinization degree of the material reaches 85%.

[0039] (3) Then crush the treated broken rice into 100-mesh rice flour, add enzyme preparation and mix evenly. The enzyme preparation added by extrusion is selected from alkaline protease, and the total addition amount is 3% (w / w) of the raw material of ric...

Embodiment 3

[0044] (1) Use the spray method to humidify the broken rice. The spray temperature is 28°C, then take it out and spread it out, dry the surface moisture of the raw material with cold wind, and set it aside for use. The dry basis moisture content of the raw material after treatment is 30% to 40%.

[0045] (2) Then use the instantaneous high-temperature fluidization technology to carry out amorphization pretreatment on the broken rice. After the humidification treatment, it is transported into a high-temperature fluidization machine with a fluidization temperature of 235°C and a fluidization time of 40s. After treatment, it is discharged from the discharge port. , so that the gelatinization degree of the material reaches 70%.

[0046] (3) Then crush the treated broken rice into 90-mesh rice flour, add enzyme preparation and mix evenly. The enzyme preparation added by extrusion is selected from alkaline protease, and the total addition amount is 2% (w / w) of the raw material of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glycemic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com