Bioactive stent of hotdog-like structure and preparation method and application thereof

A bioactive, layered structure technology, applied in the fields of manufacturing tools, additive manufacturing, tissue regeneration, etc., can solve the problems of low porosity, low drug loading efficiency, unable to form continuous pore structure, etc. Beneficial effects on adhesion and proliferation and differentiation effects, excellent drug release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

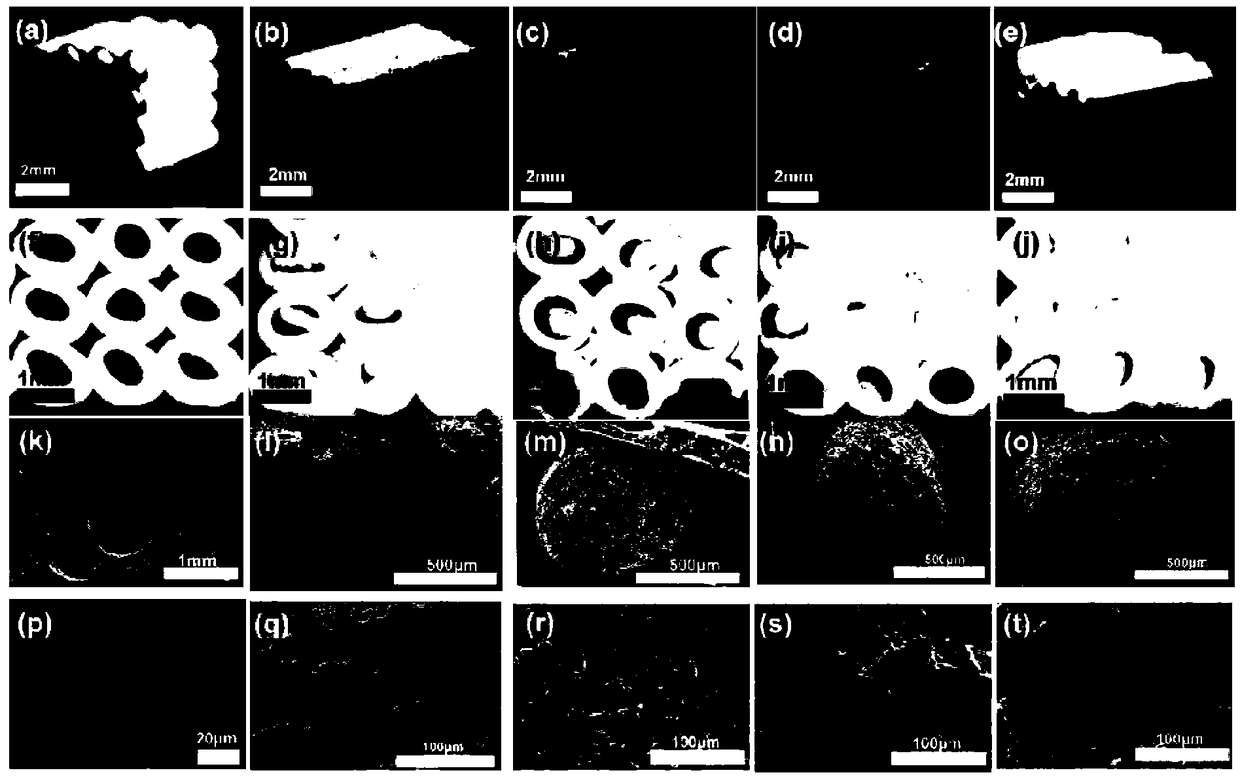

[0067] Take 5g of pure feldspar powder (purchased from Kunshan Huaqiao Technology New Material Co., Ltd.), 0.32g of sodium alginate powder and 2.5g of F127 aqueous solution with a mass fraction of 20%, after fully mixing, use 3D printing technology to prepare a hollow tube 3D printing bracket .

[0068] The printed scaffold was calcined at 1350°C for 3 hours to obtain a pure hollow tube 3D printed scaffold HT-AKT.

[0069] Preparation of ice template slurry: the mass fraction of feldspar in aqueous solution is 20%, 30%, 40%, and 50%, respectively, the mass fraction of sodium polyacrylate is 1.5%, and the mass fraction of PVA is 1.5%. Ball mill at 500r / min for 1.5h.

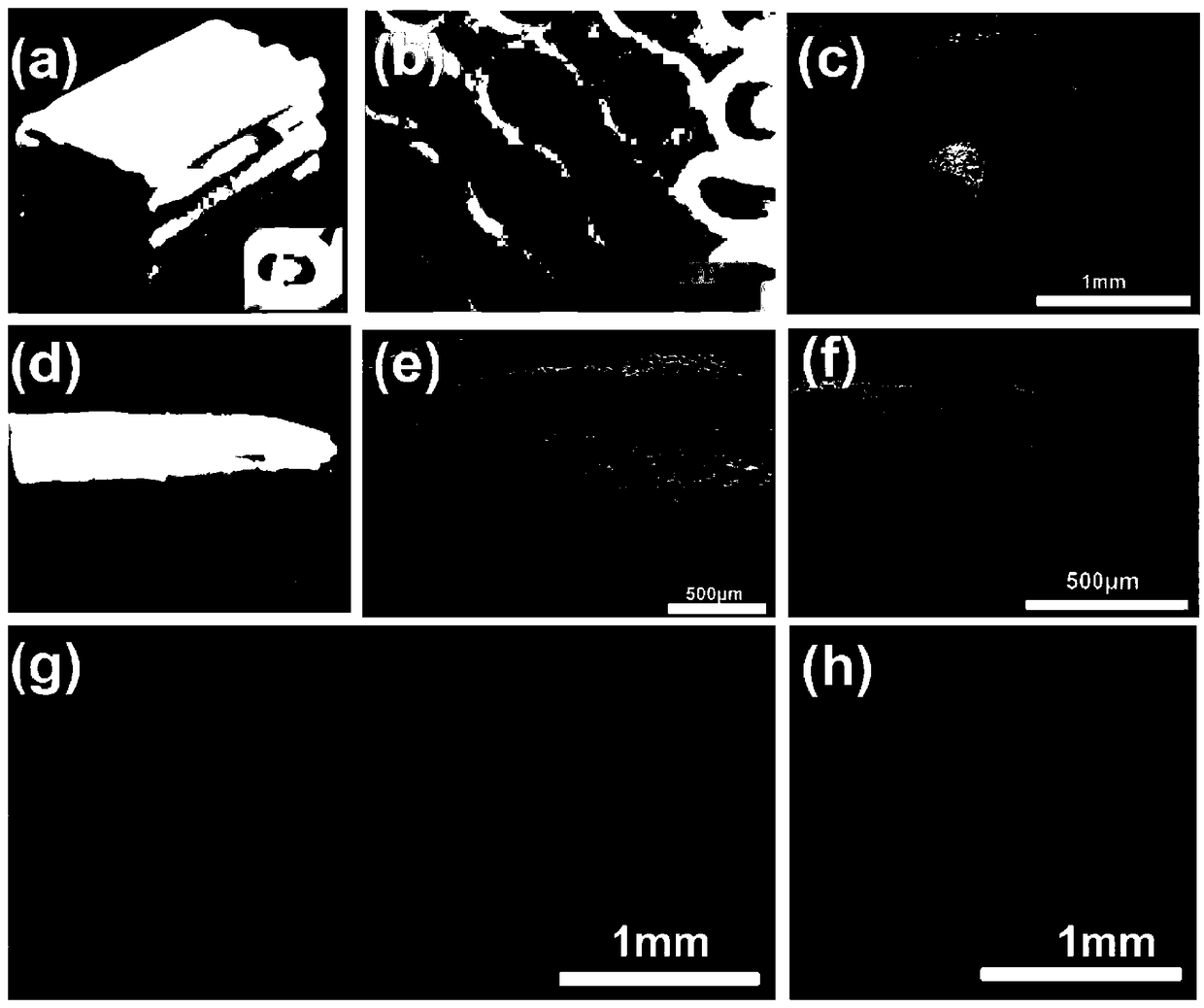

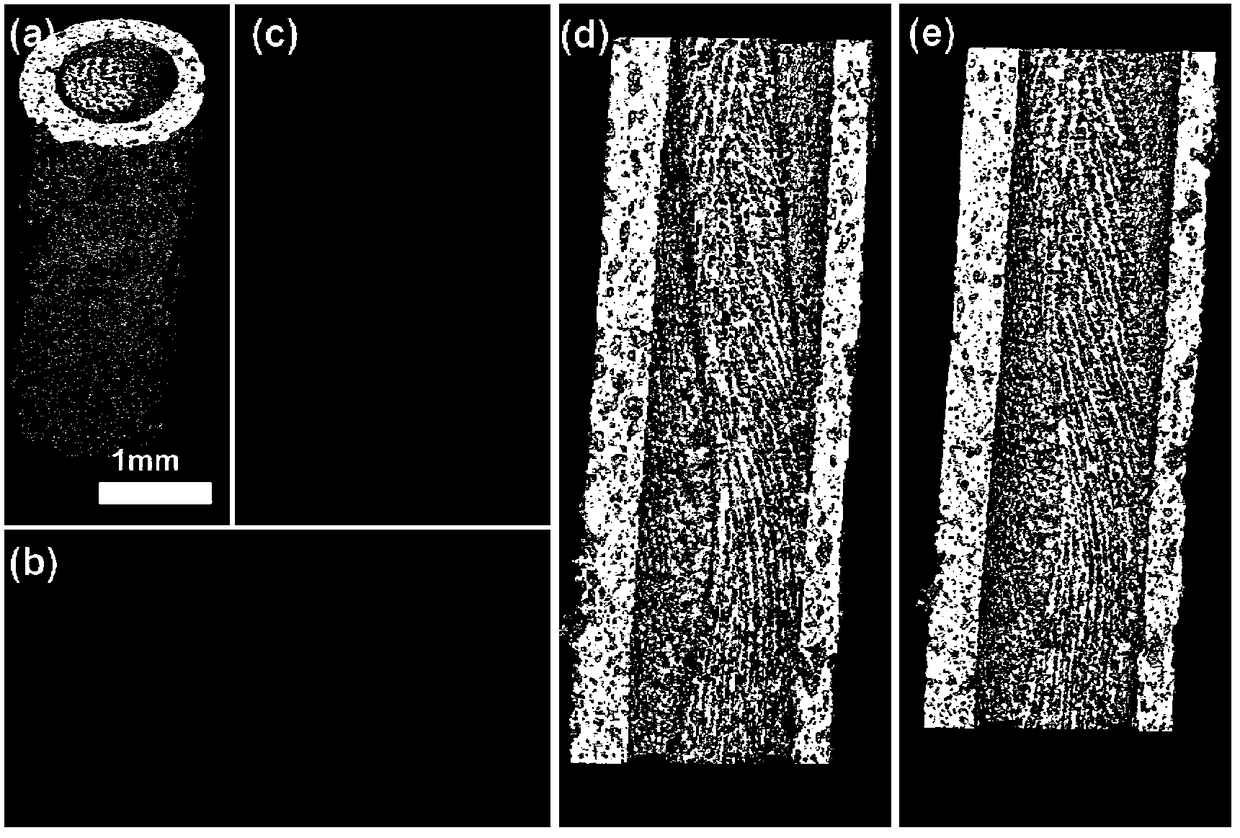

[0070] Place the hollow tube support (HT-AKT) in the mold containing the above-mentioned feldspar ice template slurry, use the ice template method, and use a one-way cold source at -70 to -80°C to freeze, so that the slurry grows into the hollow in the pipeline. Freeze-dry the obtained green body for 36 hours, ta...

Embodiment 2

[0093] Take 5g of pure β-TCP powder (purchased from Kunshan Huaqiao Technology Co., Ltd.), 0.22g of sodium alginate powder and 1.5g of F127 aqueous solution with a mass fraction of 30% are fully mixed, and then use 3D printing technology to prepare single-channel empty tube 3D printing stand.

[0094] The printed scaffold was calcined at 11000°C for 3 hours to obtain a pure single-channel 3D printed scaffold.

[0095] Prepare ice template slurry: the mass fraction of β-TCP in aqueous solution is 10%-50%, the mass fraction of sodium polyacrylate is 1%-3%, and the mass fraction of PVA is 4%-5%. Ball mill at 500r / min for 1.5-5h.

[0096] The single-channel β-TCP scaffold is placed in a mold containing 10%-50% β-TCP ice-template slurry, and the ice-template method is used to make the slurry grow into the hollow channel. The obtained green body is freeze-dried for 24-48 hours, and the scaffold embedded in the green body block is taken out and sintered at 1100° C. for 3-5 hours to...

Embodiment 3

[0098] Take 6g of pure feldspar powder, 0.3g of sodium alginate powder and 1.5g of F127 aqueous solution with a mass fraction of 20% and mix thoroughly, and then use 3D printing technology to prepare a hollow tube 3D printed scaffold.

[0099] The printed scaffold was calcined at 1350°C for 3 hours to obtain a pure hollow tube 3D printed scaffold HT-AKT.

[0100] Prepare ice template slurry: the mass fraction of graphene oxide (GO) (purchased from Haoye Co., Ltd.) in aqueous solution is 5-20%, the mass fraction of sodium polyacrylate is 1.5%-2.5%, and the mass fraction of PVA is 3 %-6%, the slurry is ball-milled for 1.5-2h in a high-energy ball mill at 500r / min.

[0101] The hollow tube support (HT-AKT) was placed in a mold containing 5%-20% GO ice templating slurry, and the ice templating method was used to make the slurry grow into the hollow tube. The obtained body was freeze-dried for 24-48 hours to obtain a GO bioceramic scaffold with imitation hot dog structure.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com