Method for preparing W/O/W type compound emulsion embedding chlorogenic acid, product and application of W/O/W type compound emulsion

A technology of chlorogenic acid and colostrum, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, applications, etc., can solve the problems of chlorogenic acid inactivation and sensitization, and achieve effective release , to promote the effect of sustained release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

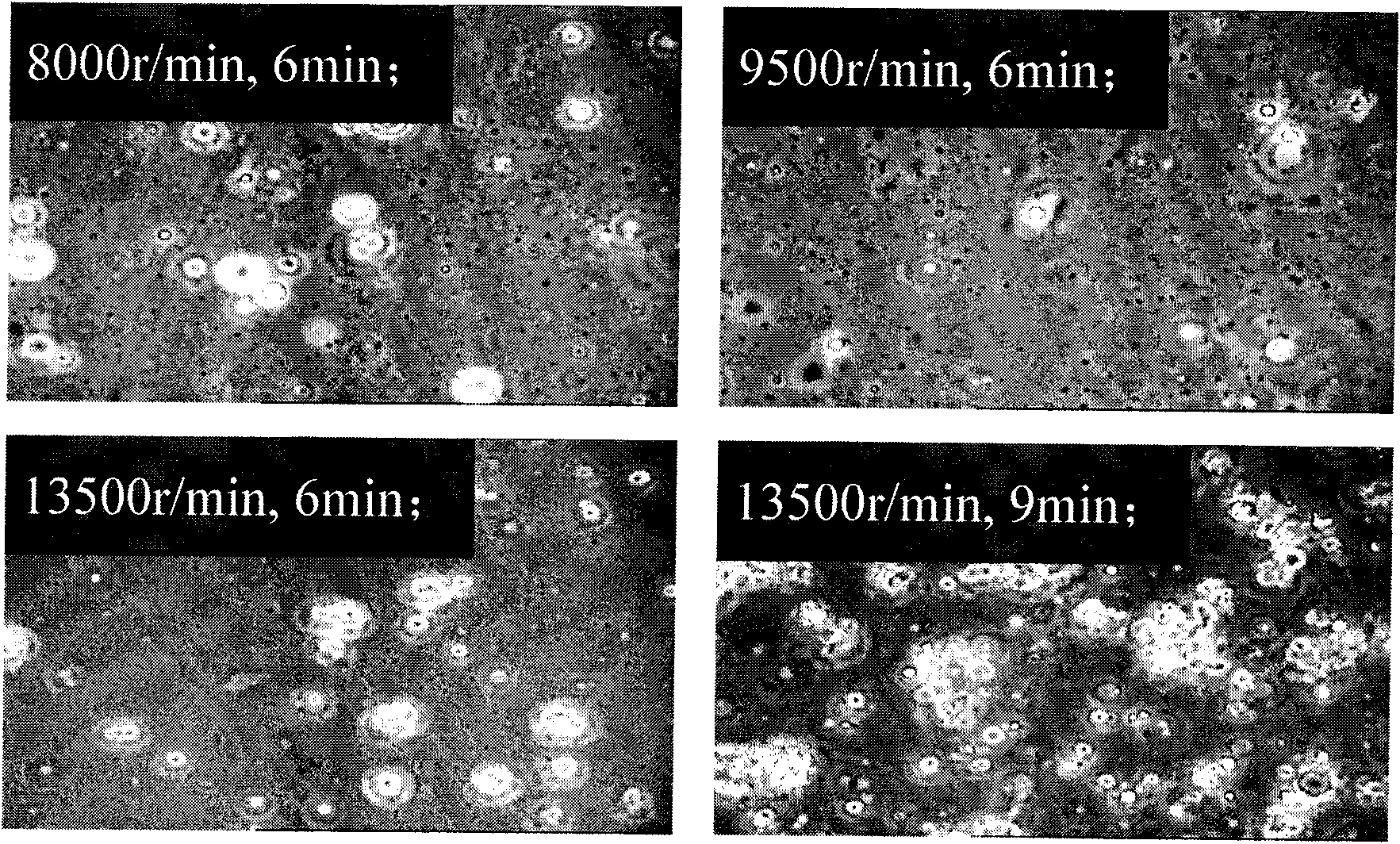

[0042] Take 9 grams of liquid paraffin as the oil phase, 1 gram of Span80 as the lipophilic emulsifier, and 9 grams of chlorogenic acid aqueous solution with a concentration of 75% as the inner water phase, mix the inner water phase, the lipophilic emulsifier and the oil phase, and mix them at high speed Stir at 8000 r / min for 6 min on a dispersing homogenizer to prepare colostrum. In this way, the mass concentration of the emulsifier in the oil phase is 10%, the mass ratio of the inner water phase to the oil phase is 1:1, and the content of the chlorogenic acid aqueous solution in the colostrum is 35.5%.

[0043]Dilute the colostrum 10 times in liquid paraffin, take the sample on Angel AQ-2010C high-power phase contrast microscope, observe its structure and particle size with an oil lens and take its micrograph, take a small amount of sample and place it on a clean glass slide , cover with a cover glass, put it under a microscope, adjust the microscope to observe the microstr...

Embodiment 2

[0045] Colostrum was prepared in the same ratio as in Example 1, except that the components were mixed and then stirred at 9500 r / min for 6 minutes on a high-speed dispersing homogenizer.

[0046] Dilute the colostrum 10 times in liquid paraffin, take the sample on Angel AQ-2010C high-power phase contrast microscope, observe its structure and particle size with an oil lens and take its micrograph, take a small amount of sample and place it on a clean glass slide , cover with a cover glass, put it under a microscope, adjust the microscope to observe the microstructure of the sample, and take micrographs of the sample with the camera that comes with the microscope.

[0047] Example 2

[0048] Colostrum was prepared in the same ratio as in Example 1, except that the components were mixed and then stirred at 9500 r / min for 6 minutes on a high-speed dispersing homogenizer.

[0049] Dilute the colostrum 10 times in liquid paraffin, take the sample on Angel AQ-2010C high-power phase...

Embodiment 3

[0051] Colostrum was prepared in the same ratio as in Example 1, except that the components were mixed and then stirred at 13500 r / min for 6 minutes on a high-speed dispersing homogenizer.

[0052] Dilute the colostrum 10 times in liquid paraffin, take the sample on Angel AQ-2010C high-power phase contrast microscope, observe its structure and particle size with an oil lens and take its micrograph, take a small amount of sample and place it on a clean glass slide , cover with a cover glass, put it under a microscope, adjust the microscope to observe the microstructure of the sample, and take micrographs of the sample with the camera that comes with the microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com