Waste heat recovery process and device

A kind of waste heat recovery equipment and waste heat recovery technology, applied in waste heat recovery process and its equipment, waste heat recovery process field, can solve the problems of unsatisfactory, environmental pollution, waste water reuse without replacement heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A waste heat recovery process

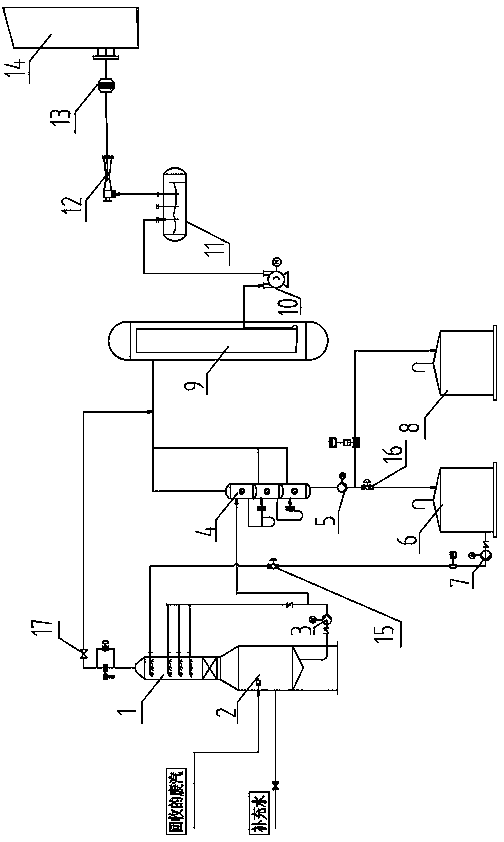

[0027] Such as figure 1 As shown, the present invention provides a waste heat recovery process, which is described by taking the case of pulping and papermaking cooking waste gas treatment as an example: when the system is started, clean water is injected into the heat storage tower 2 as a circulating fluid, and the cooking waste gas enters the heat storage tower 2 through the collection pipe. In the steam chamber at the upper part of the heat storage tower 2, the waste gas is initially depressurized and separated from the vapor and liquid. After separation, the waste gas enters through the built-in gas distributor of the absorption tower 1. (Circulating liquid or flash low-temperature water) is in a highly dispersed state, forming a full coverage of liquid in the tower. The lower main components are the gas distributor and the packing area. The gas distributor can make the gas entering the distributor under extremely high ki...

Embodiment 2

[0031] Embodiment 2 A kind of waste heat recovery equipment

[0032] Such as figure 1As shown, the present invention provides a waste heat recovery device, including an absorption tower 1, a heat storage tower 2, a circulation pump 3, a multi-stage flash tank 4, a return pump 5, a return tank 6, a liquid distribution pump 7, a sewage tank 8, Evaporation and concentration equipment 9, vacuum pump 10, odor collector 11, injector 12, flame arrester 13, burner 14.

[0033] The top of the heat storage tower 2 is connected to the absorption tower 1, and one side of the heat storage tower 2 is provided with a supplementary water port and a waste gas inlet;

[0034] The absorption tower 1 is provided with a two-layer nozzle pipe liquid distributor, and the two-layer nozzle pipe liquid distributor includes a lower nozzle pipe liquid distributor located in the middle of the absorption tower 1 and an upper nozzle pipe liquid distributor located at the upper part of the absorption tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com