Gas-liquid-solid three-phase reaction bypass monitoring device and application of gas-liquid-solid three-phase reaction bypass monitoring device to storing carbon dioxide mineral

A three-phase reaction and monitoring device technology, applied in measuring devices, chemical/physical processes, specific gravity measurement, etc., can solve the problems of demister mesh blockage, densitometer fouling, poor reliability, etc., to achieve rapid analysis and Judgment, improvement of safety and accuracy, effect of accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

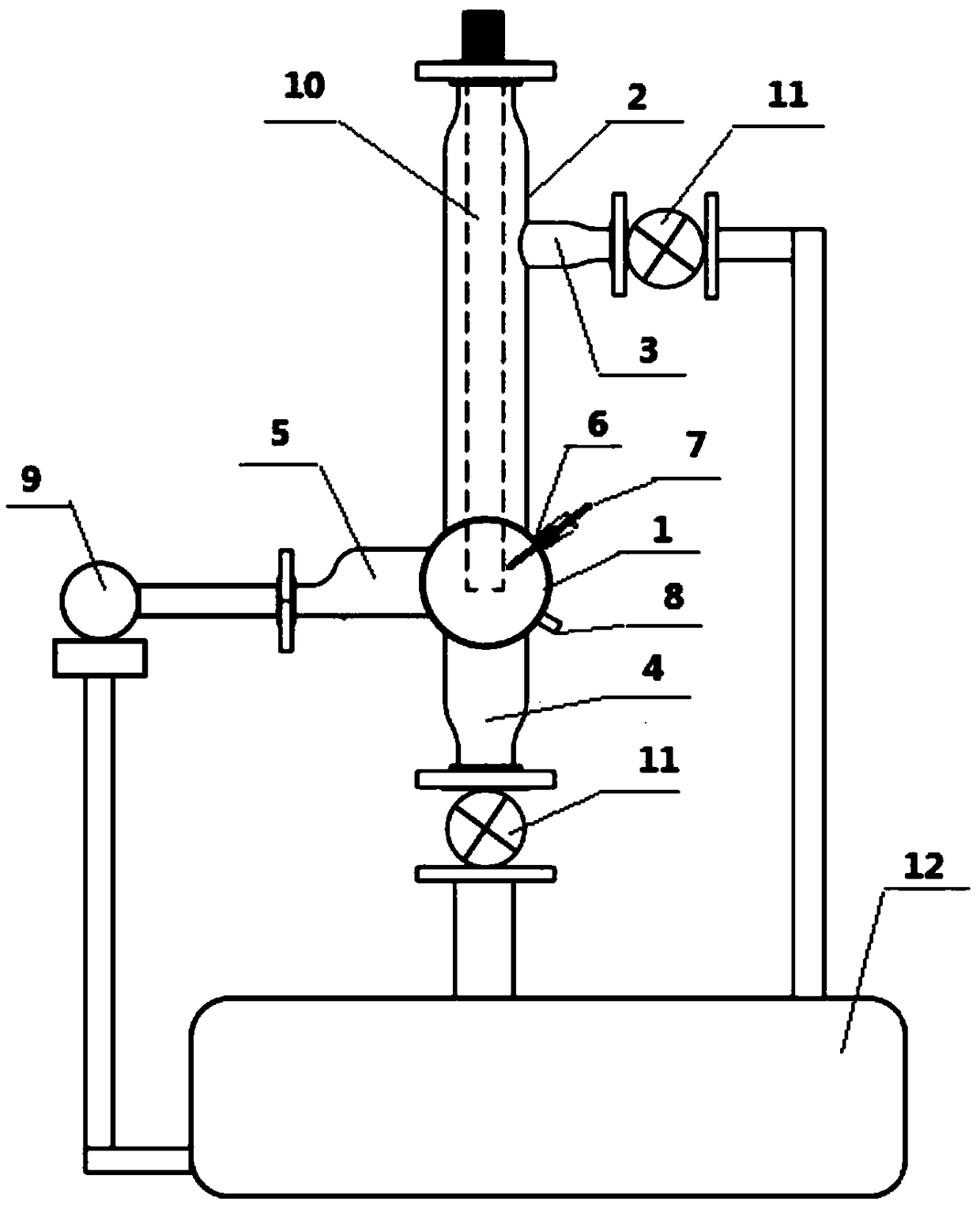

[0028] Such as figure 1 , a bypass monitoring device for a gas-liquid-solid three-phase reaction, comprising a horizontal cylindrical monitoring chamber 1, an eccentric reducer 5, a tuning fork density meter 10 and a pH meter 7, the monitoring chamber 1 above A density meter placement tube 2 is arranged vertically, the bottom of the density meter placement tube 2 communicates with the monitoring cavity 1, a tuning fork density meter 10 is inserted into the top entrance of the density meter placement tube 2, and the measuring end of the tuning fork density meter 10 extends into the In the monitoring cavity 1; the upper side wall of the density meter placement pipe 2 is provided with a gas phase branch pipe 3, one end of the gas phase branch pipe 3 communicates with the density meter placement pipe 2, and the other end is connected to the gas-liquid-solid three-phase reactor through a ball valve 11 and a pipeline 12 connected; the vertical direction below the monitoring chamber ...

Embodiment 2

[0037] In the bypass monitoring device for the gas-liquid-solid three-phase reaction, the ratio of the inner diameter of the small end section of the eccentric reducer 5 to the inner diameter of the large end section is 1:2; the length of the large end section of the eccentric reducer is 40cm; The height of the tube where the density meter is placed is 60 cm; the gap between the tuning fork densitometer and the wall of the tube where the density meter is placed is 20 mm, and the rest are the same as in Example 1.

[0038] The device is applied to carbon dioxide mineral storage, the application method:

[0039] (1) 5 cubic meters of reaction solutions containing 1M ammonium chloride, 0.2M magnesium chloride are loaded into the gas-liquid-solid three-phase reactor of 8 cubic meters, blow into the flue gas that contains 15% carbonic acid gas with the flow rate of 300 cubic meters per hour, At the same time, add ammonia to keep the pH value of the reaction solution at 9.3, and fee...

Embodiment 3

[0045] In the bypass monitoring device for the gas-liquid-solid three-phase reaction, the ratio of the inner diameter of the small end section of the eccentric reducer 5 to the inner diameter of the large end section is 1:2.2; the length of the large end section of the eccentric reducer is 60cm; The height of the tube where the density meter is placed is 80 cm; the gap between the tuning fork densitometer and the wall of the tube where the density meter is placed is 15 mm, and the rest are the same as in Example 1.

[0046] The device is applied to carbon dioxide mineral storage, the application method:

[0047] (1) 5 cubic meters of tap water are loaded into the magnesium carbonate ammonium hydrate reactor of 8 cubic meters, and 1000 kilograms of magnesium carbonate ammonium hydrate crude products are added in the reactor with a flow rate of 25 kilograms per minute, and 90% Nitrogen-depleted carbon dioxide tail gas; start the peristaltic pump, and pump the gas-liquid-solid th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com