Synthesis method of PEDOT loaded graphene

A synthesis method and graphene technology, applied in the field of material chemistry, can solve the problems of severe aggregation, phase separation, poor dispersion, and difficulty in obtaining nanocomposites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

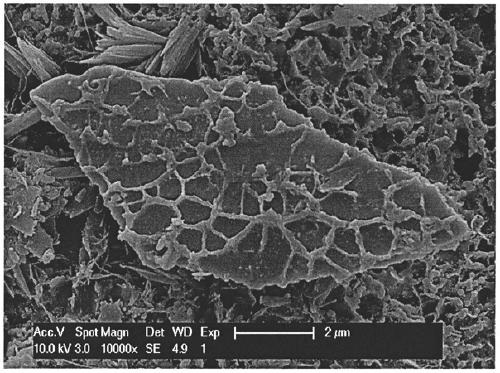

[0010] 0.01molL -1 EDOT monomer is dissolved in 50mL isopropanol, and 3gL is added -1 Graphite oxide is ultrasonically stirred and dispersed to form a sol; 0.05molL -1 Dissolve ferric chloride in 30mL deionized water solution, slowly add to the first sol, continue to stir during the addition, to obtain the mixed mother liquor; add 20mL 0.3molL -1 Potassium iodide solution, keep stirring at room temperature and react for 24 hours to get a precipitate, wash and dry the precipitate to get figure 1 The PEDOT shown supports graphene powder, and the PEDOT laminated sheets are attached to the graphene. After the powder is compacted by a cold press, the conductivity is 101S / cm.

Embodiment 2

[0012] 0.04molL -1 EDOT monomer is dissolved in 50mL isopropanol, and 2gL is added -1 Graphite oxide is ultrasonically stirred and dispersed to form a sol; 0.12molL -1 Dissolve ferric chloride in 30mL deionized water solution, slowly add to the first sol, continue to stir during the addition, to obtain the mixed mother liquor; add 20mL 0.5molL -1 The potassium iodide solution was stirred and reacted at room temperature for 8 hours to obtain a precipitate, and the precipitate was washed and dried to obtain PEDOT-supported graphene powder. The electrical conductivity of the powder after compaction with a cold press is 108S / cm.

Embodiment 3

[0014] 0.03molL -1 EDOT monomer is dissolved in 50mL isopropanol, and 1gL is added -1 Graphite oxide is ultrasonically stirred and dispersed to form a sol; 0.2molL -1 Dissolve ferric chloride in 30mL deionized water solution, slowly add to the first sol, continue to stir during the addition, to obtain the mixed mother liquor; add 20mL 0.8molL -1 The potassium iodide solution was stirred and reacted at room temperature for 8 hours to obtain a precipitate, and the precipitate was washed and dried to obtain PEDOT-supported graphene powder. After the powder is compacted by a cold press, the conductivity is 97S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com