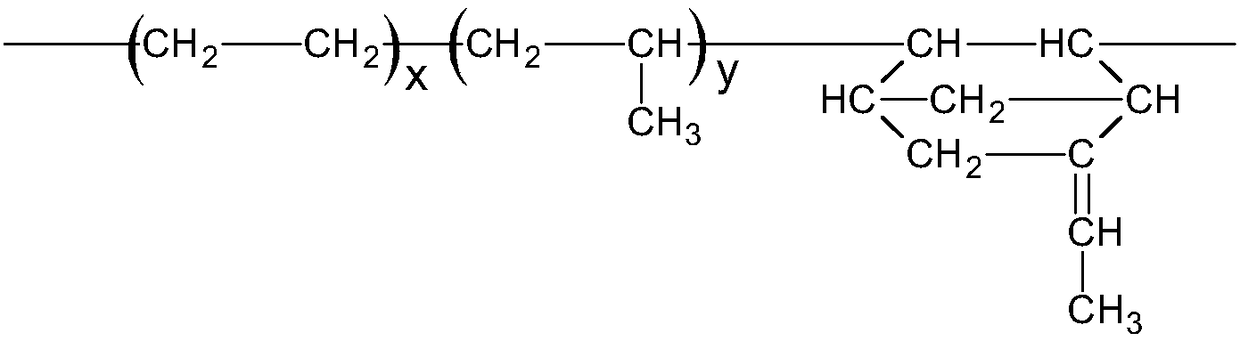

Ethylene-propylene-diene monomer rubber seal strip and preparation method thereof

A EPDM rubber and sealing strip technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of aging, affecting the sealing performance, shock absorption performance and service life of the sealing strip, and easy to deform, and achieve Good low temperature resistance, meeting application requirements and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

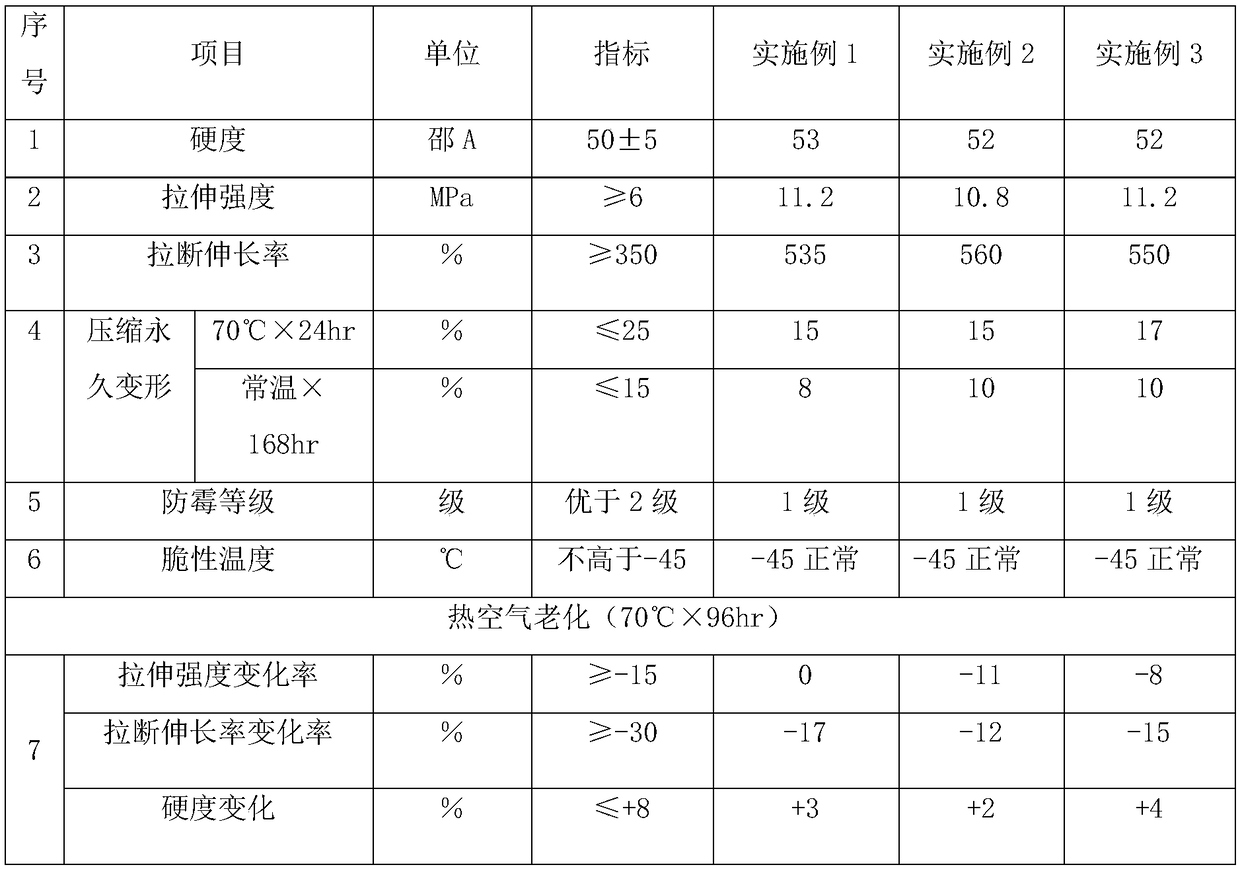

Examples

Embodiment 1

[0026] This embodiment provides an EPDM sealing strip, which is made of the following raw materials in parts by weight: 170 parts of EPDM rubber, 75 parts of carbon black, 10 parts of white carbon black, and 5 parts of peroxide vulcanizing agent , 9 parts of zinc oxide, 14 parts of magnesium oxide, 13 parts of paraffin oil, 2 parts of accelerator TMTD, 2 parts of stearic acid, 2 parts of antioxidant MB, and 2 parts of coupling agent.

[0027] Wherein, the peroxide vulcanizing agent is an alkyl peroxide, the paraffin oil is a paraffin oil with a flash point above 280°C and an aromatic content of 0%, and the coupling agent is a silane coupling agent.

[0028] A kind of preparation method of above-mentioned EPDM sealing strip, comprises the steps:

[0029] S1, weigh each raw material of corresponding weight part respectively;

[0030] S2. Add EPDM rubber to the internal mixer for masticating for 6 minutes, and the masticating temperature is 115°C, then add carbon black, white ca...

Embodiment 2

[0035] This embodiment provides an EPDM sealing strip, which is made of the following raw materials in parts by weight: 150 parts of EPDM rubber, 60 parts of carbon black, 12 parts of white carbon black, and 3 parts of peroxide vulcanizing agent , 12 parts of zinc oxide, 12 parts of magnesium oxide, 10 parts of paraffin oil, 1 part of accelerator TMTD, 1 part of stearic acid, 1 part of antioxidant MB, and 1 part of coupling agent.

[0036] Among them, the peroxide vulcanizing agent is diacyl peroxide, the paraffin oil is paraffin oil with a flash point above 280° C. and the content of aromatic hydrocarbon is 0%, and the coupling agent is a titanate coupling agent.

[0037] A kind of preparation method of above-mentioned EPDM sealing strip, comprises the steps:

[0038] S1, weigh each raw material of corresponding weight part respectively;

[0039] S2. Add EPDM rubber into the internal mixer for 5min mastication, the mastication temperature is 110°C, then add carbon black, whi...

Embodiment 3

[0044] This embodiment provides an EPDM sealing strip, which is made of the following raw materials in parts by weight: 180 parts of EPDM rubber, 90 parts of carbon black, 8 parts of white carbon black, and 8 parts of peroxide vulcanizing agent , 6 parts of zinc oxide, 16 parts of magnesium oxide, 18 parts of paraffin oil, 3 parts of accelerator TMTD, 3 parts of stearic acid, 3 parts of antioxidant MB, and 3 parts of coupling agent.

[0045] Wherein, the peroxide vulcanizing agent is an alkyl peroxide, the paraffin oil is a paraffin oil with a flash point above 280°C and an aromatic content of 0%, and the coupling agent is a silane coupling agent.

[0046] A kind of preparation method of above-mentioned EPDM sealing strip, comprises the steps:

[0047] S1, weigh each raw material of corresponding weight part respectively;

[0048] S2. Add EPDM rubber to the internal mixer for mastication for 8 minutes, and the mastication temperature is 125°C, then add carbon black, white car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com