Photoelectric coupling mechanism and manufacturing method thereof

A technology of photoelectric coupling and manufacturing method, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of inconvenient adjustment and observation of microlens array, complex and time-consuming assembly process, and small coupling tolerance, etc., and can be implemented High reliability, wide tolerance tolerance and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

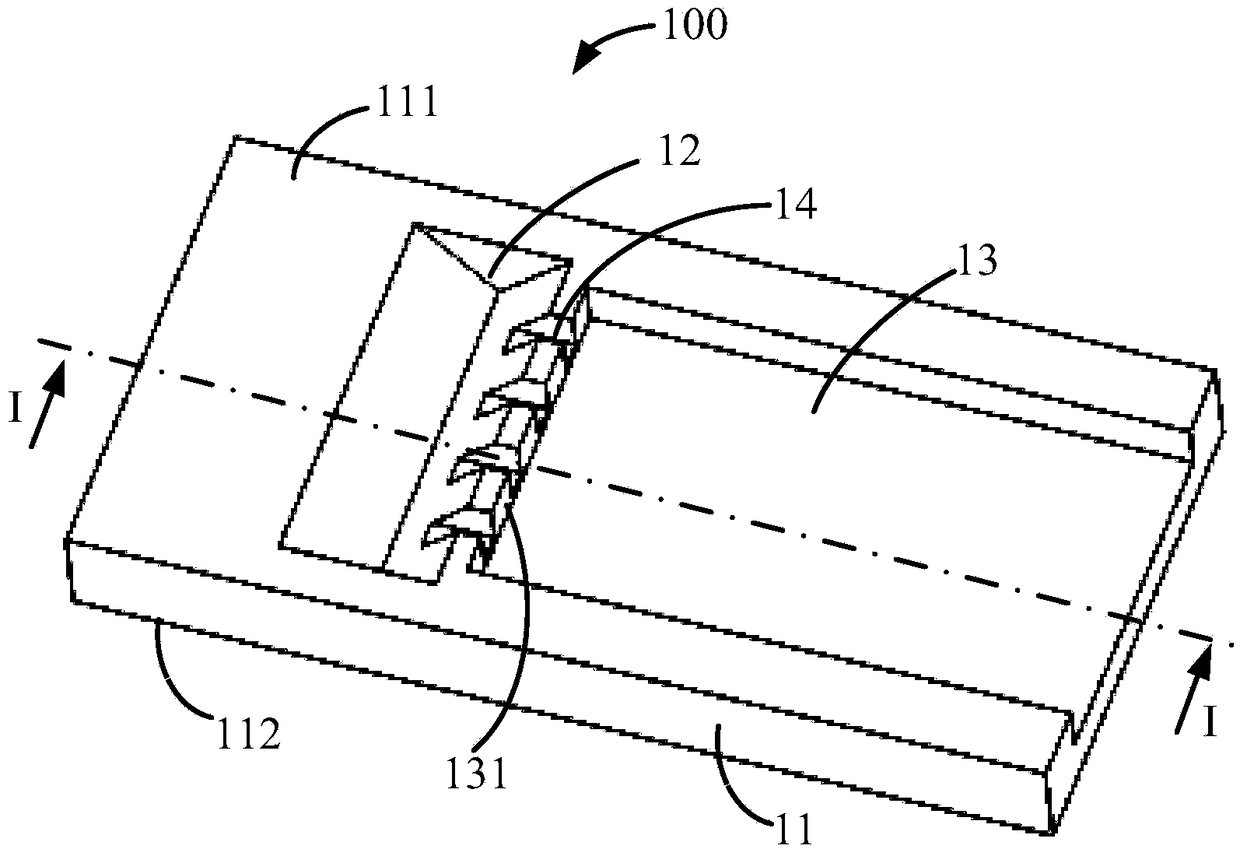

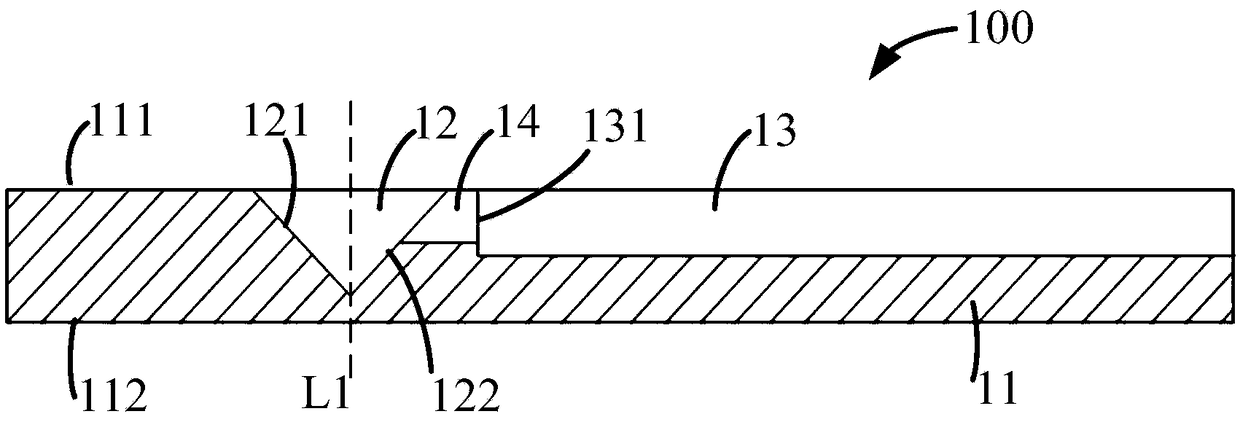

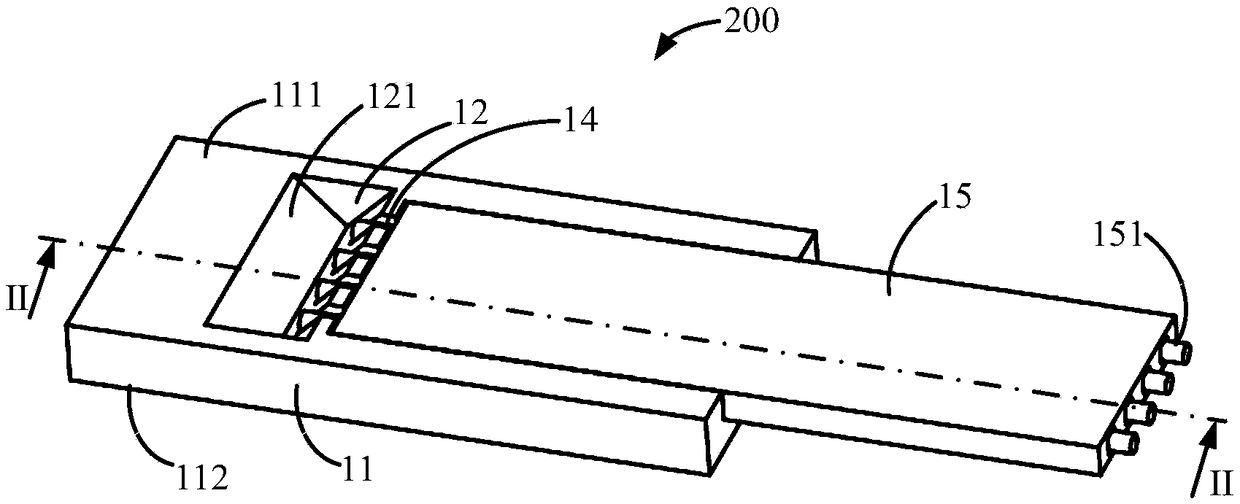

[0019] Such as Figure 1 to Figure 4 As shown, a kind of optocoupler mechanism 100 of the present invention is manufactured on rigid printed circuit board substrate 11 such as utilizing FR4 or PTFE, and substrate 11 can be materials such as FR4 or PTFE; A surface 111 and a second surface 112 and the first groove 12 and the second groove 13, the first groove 12 and the second groove 13 are all recessed from the first surface 111 to the second surface 112; A groove 12 has a first reflective surface 121 and a second plane 122 perpendicular to each other, which are processed by a 90° "V" type dicing machine or other methods, and the first reflective surface 121 faces the direction of the second groove 13; The included angle between the first reflective surface 121 and the first surface 111 of the substrate 11 is 45°. Through simulation and experiment, the included angle is 43° to 47°, which can ensure a good range of coupling efficiency; the described first A reflective surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com