Groove preparation method of GaN-based material

A base material, non-concave technology, applied in the field of groove preparation of GaN base materials, can solve the problems of deterioration of GaN surface characteristics, affecting the dynamic characteristics of the device, affecting the electrical characteristics of the device, etc., which is conducive to large-scale implementation and high operability. and repeatability, the effect of improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below through specific embodiments and accompanying drawings.

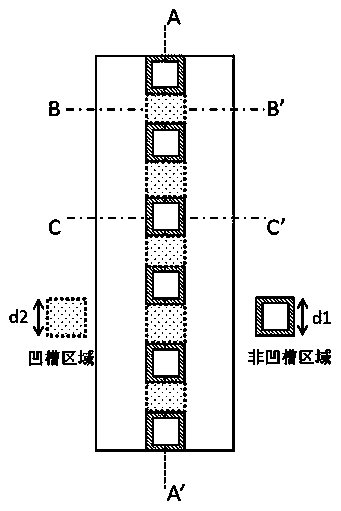

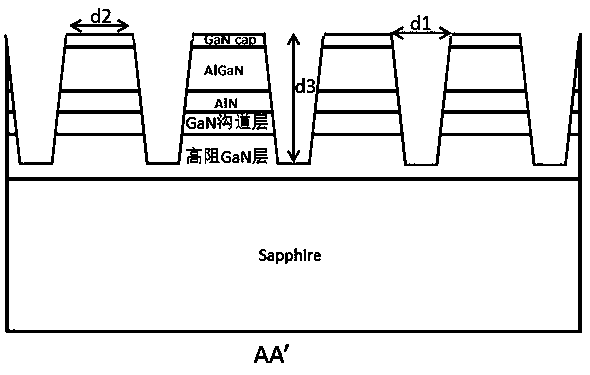

[0029] Taking AlGaN / GaN materials as an example, figure 1 It is the specific epitaxial wafer structure of this embodiment, including from bottom to top: 1) epitaxial substrate Sapphire; 2) GaN buffer; 3) sacrificial layer, namely 2nm AlN, with a thickness of 1-5nm; 4) barrier layer, That is, 20nm AlGaN; 5) GaN capping layer (GaN cap), the thickness of which is 2-5nm, and 2nm is selected for specific preparation in this embodiment.

[0030] The method of etching the non-groove area can be selected by ICP etching or RIE etching.

[0031] The depth of the etched non-groove region is greater than the sum of the thicknesses of the sacrificial layer, the barrier layer and the GaN capping layer, that is, it needs to be etched at least to the GaN buffer layer.

[0032] Further, the corrosive solution can selectively corrode only the sacrificial layer without affec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com