GaN thin film-based miniature flexible ultraviolet detector and fabrication method thereof

A technology of ultraviolet detector and gallium nitride, which is applied in the direction of semiconductor devices, climate sustainability, and final product manufacturing, etc., can solve the problems of inability to achieve flexibility, preparation materials and substrates that are difficult to bend, and achieve flexibility , reduce dislocation and relieve stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

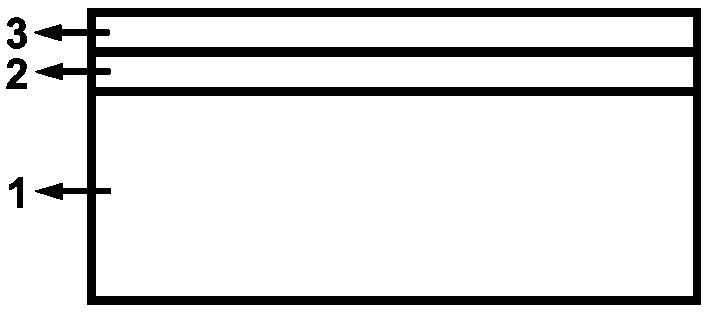

[0024] See attached figure 1 , which is a schematic diagram of the structure of a gallium nitride film grown on a graphene / dielectric material provided in this embodiment, a graphene intercalation layer 2 is grown on a dielectric material 1 to obtain a graphene / dielectric material composite substrate, and on the composite substrate To re-grow gallium nitride thin film 3, the specific preparation steps are as follows:

[0025] Step 1, preparing a graphene / dielectric material composite substrate. The dielectric material 1 provided in this embodiment is silicon carbide, and a multi-layer step-structured graphene insertion layer 2 is grown on its surface by high-temperature thermal sublimation. The specific steps are as follows : Hydrogen gas is introduced at a high temperature of 1575°C, silicon atoms on the surface of silicon carbide escape under hydrogen etching, leaving carbon atoms to restructure to form graphene, and a graphene / silicon carbide composite substrate is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com