Regular hexagonal ebg structure for antenna and its manufacturing process

A technology of regular hexagon and manufacturing process, which is applied in antennas, antenna couplings, antenna components, etc., can solve the problems of difficulty in meeting the miniaturization requirements of wireless communication, poor symmetry performance of dense packing performance, and uneven band gap characteristics, etc. , to achieve the effect of reliable and easy manufacturing process, small matrix porosity and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

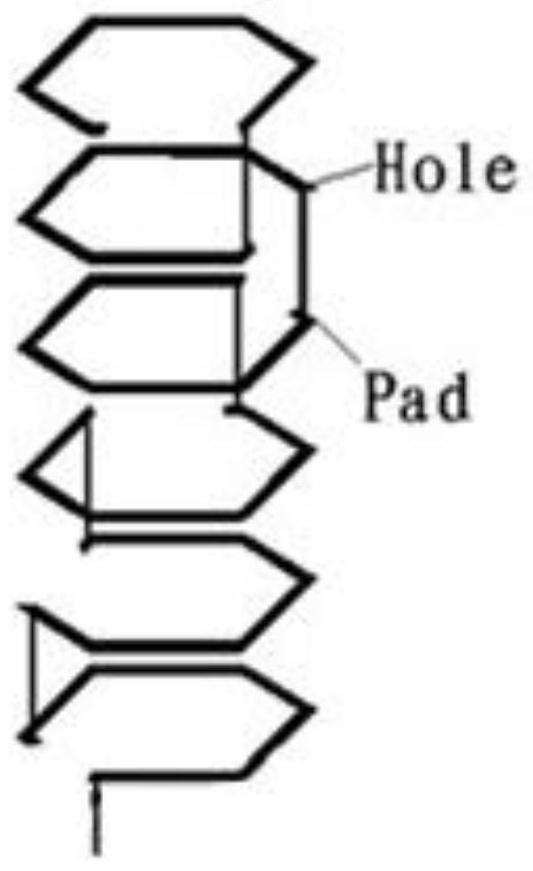

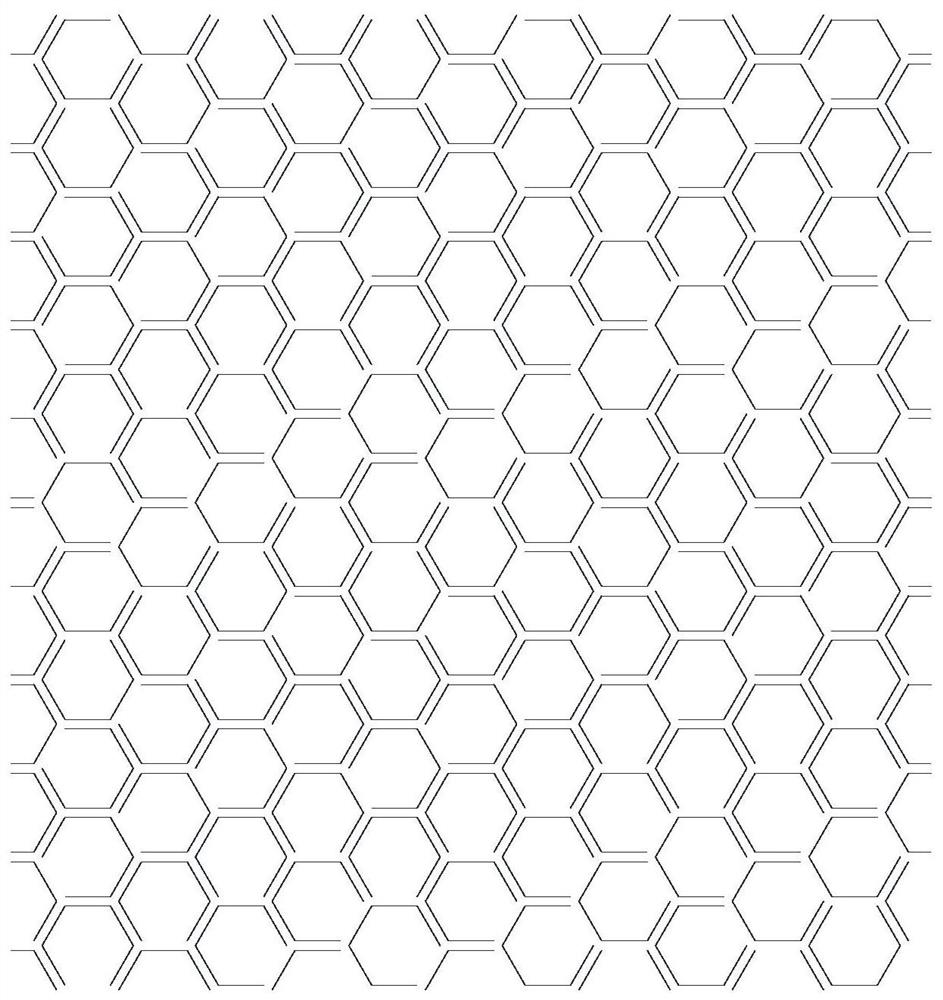

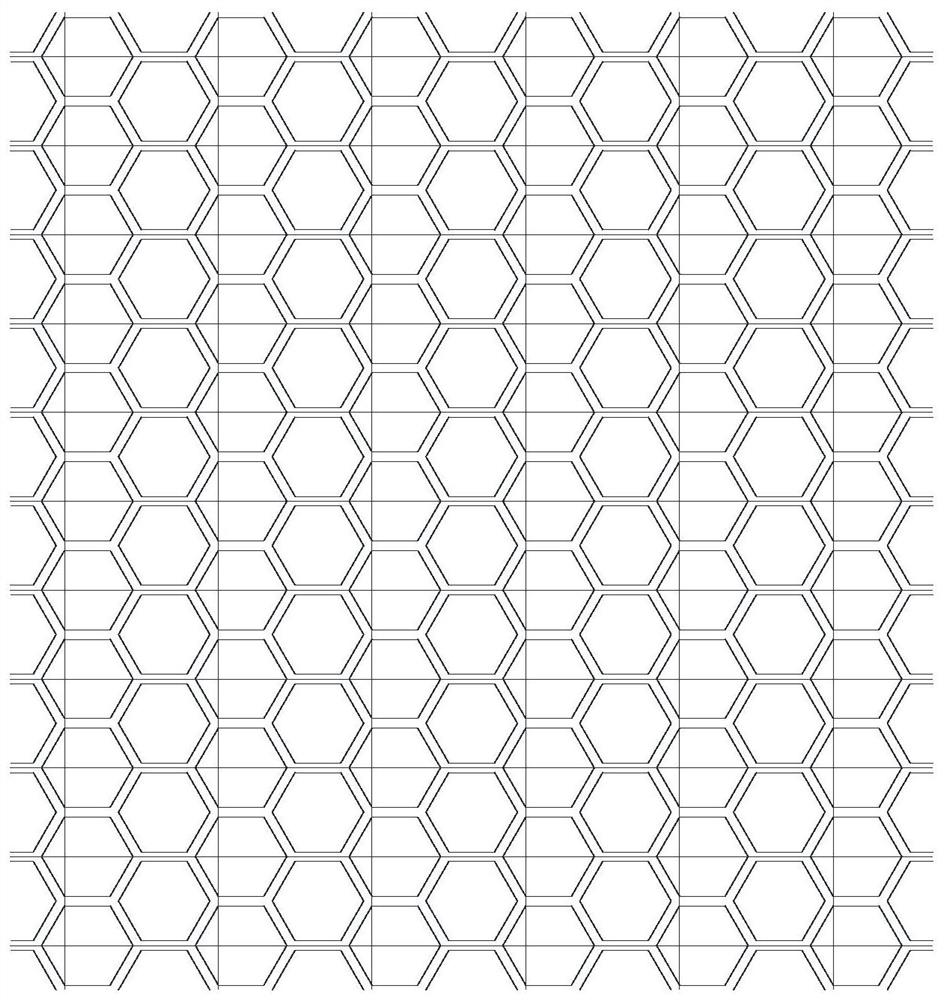

[0072] In this embodiment, from top to bottom, the MARK layer, the first-order whiteboard layer group, the coil layer group, the bottom electrode layer, and the second-order whiteboard layer group are superimposed. Among them, the MARK layer is a raw tape layer printed with MARK graphics, and the number of this layer is one; the first-order whiteboard layer group includes six whiteboard layers; the coil layer group includes 18 coil layers, and the coils on the coil layer are composed of several regular hexagonal layers. An array formed by the periodic arrangement of inductance coils in the shape of one side missing, each inductance coil is conductively connected to the inductance coil of the next coil layer through a through hole; the coils on the bottom electrode layer are regularly arranged by a complete regular hexagonal inductance coil cloth, and the inductance coils are connected by conductors in two directions perpendicular to each other in a straight line to realize the ...

Embodiment 2

[0075] The present embodiment is the manufacturing process of embodiment 1, and it comprises the following operation steps:

[0076] 1). Slurry preparation;

[0077] The slurry preparation is the same as the traditional LTCC slurry preparation method. The slurry raw material is a borosilicate glass / ceramic composite system. The dielectric constant of the composite material is 4.6-5.0, and the composition is Al 2 o 3 -B 2 o 3 -SiO 2 -R 2 O, where R 2 O is an alkali metal oxide, the solvent used to prepare the ceramic slurry is toluene and isopropanol, the plasticizer is dioctyl adipate and dibutyl phthalate, and the binder is polymethyl methacrylate , the dispersant is phosphoric acid ester;

[0078] 2). Casting: the slurry prepared in step 1) is dry-cast to obtain a green tape with a thickness of 50 μm, and the raw tape is attached to the PET film, and after cutting, a green tape unit of a fixed size is formed;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com