Raw Material For Thixomolding, Method For Producing Raw Material For Thixomolding, And Molded Body

A technology of thixotropic deformation and manufacturing method, which is applied in the direction of transportation and packaging, metal processing equipment, etc., and can solve problems such as dripping, nozzle clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Next, specific embodiments of the present invention will be described.

[0103] 1. Manufacturing of formed bodies

[0104] Sample No.1

[0105] [1] First, the raw material is melted in a high-frequency induction furnace, and powdered by a high-speed rotating water stream atomization method, to obtain a raw material for thixoforming formed of magnesium-based alloy powder. The alloy composition of the obtained magnesium-based alloy powder is shown in Table 1.

[0106] The setting conditions of the high-speed rotating water jet atomization device (powder manufacturing device) are as follows.

[0107] ·The spray pressure of the coolant: 100MPa

[0108] ·The temperature of the coolant: 30℃

[0109] ·Temperature of molten metal: melting point of raw material +20℃

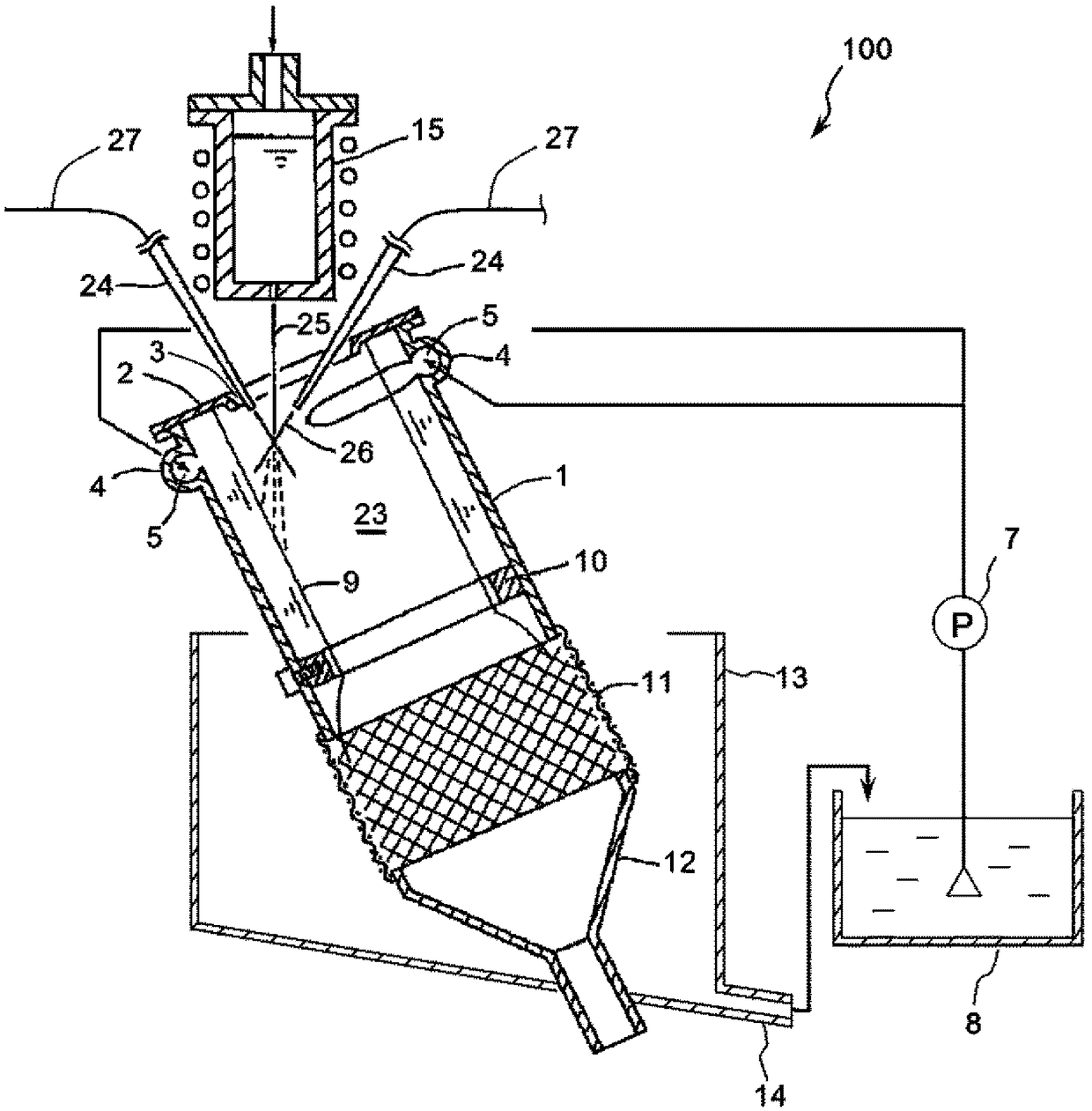

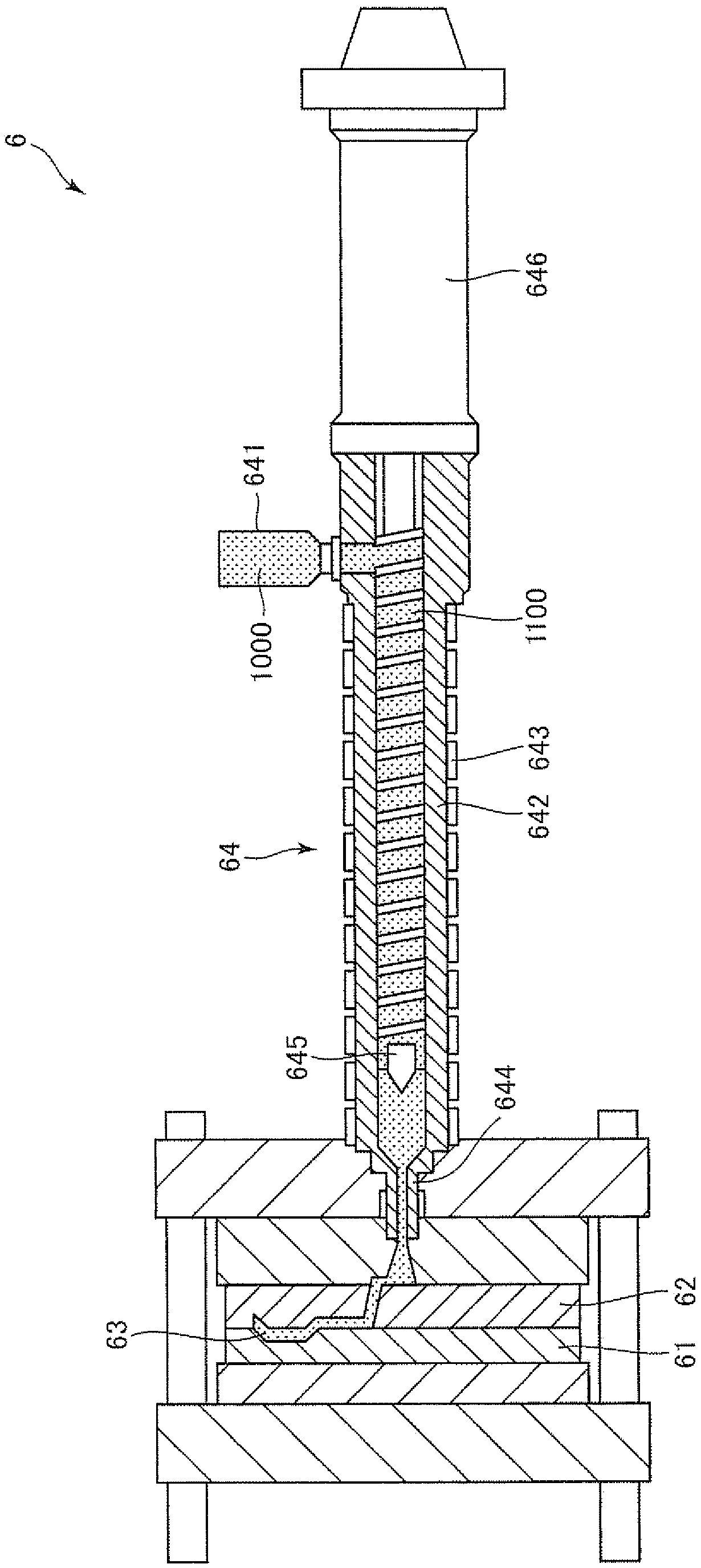

[0110] [2] Next, the raw material for thixoforming is molded by the thixoforming method using an injection molding machine. Thus, a molded body is obtained. In addition, the molding conditions at this time are as follows.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com