Mesoporous bentonite and preparation method thereof

A bentonite and mesoporous technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high energy consumption, difficult separation, and potential environmental damage, achieve uniform pore size distribution, reduce pore size, Easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention discloses a mesoporous bentonite, which is prepared by taking bentonite as a raw material through acid-base etching.

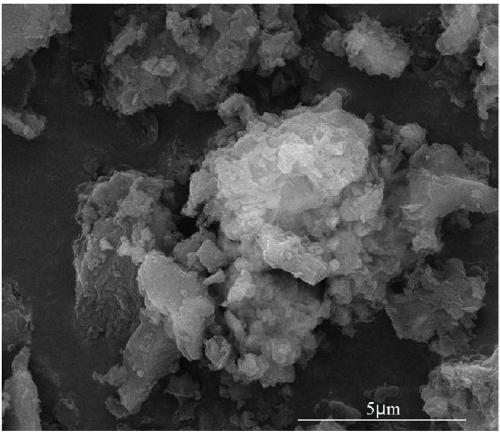

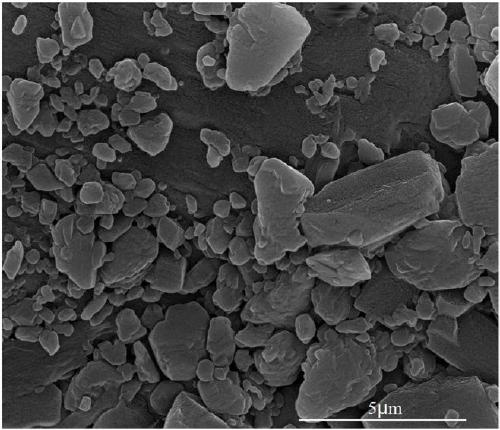

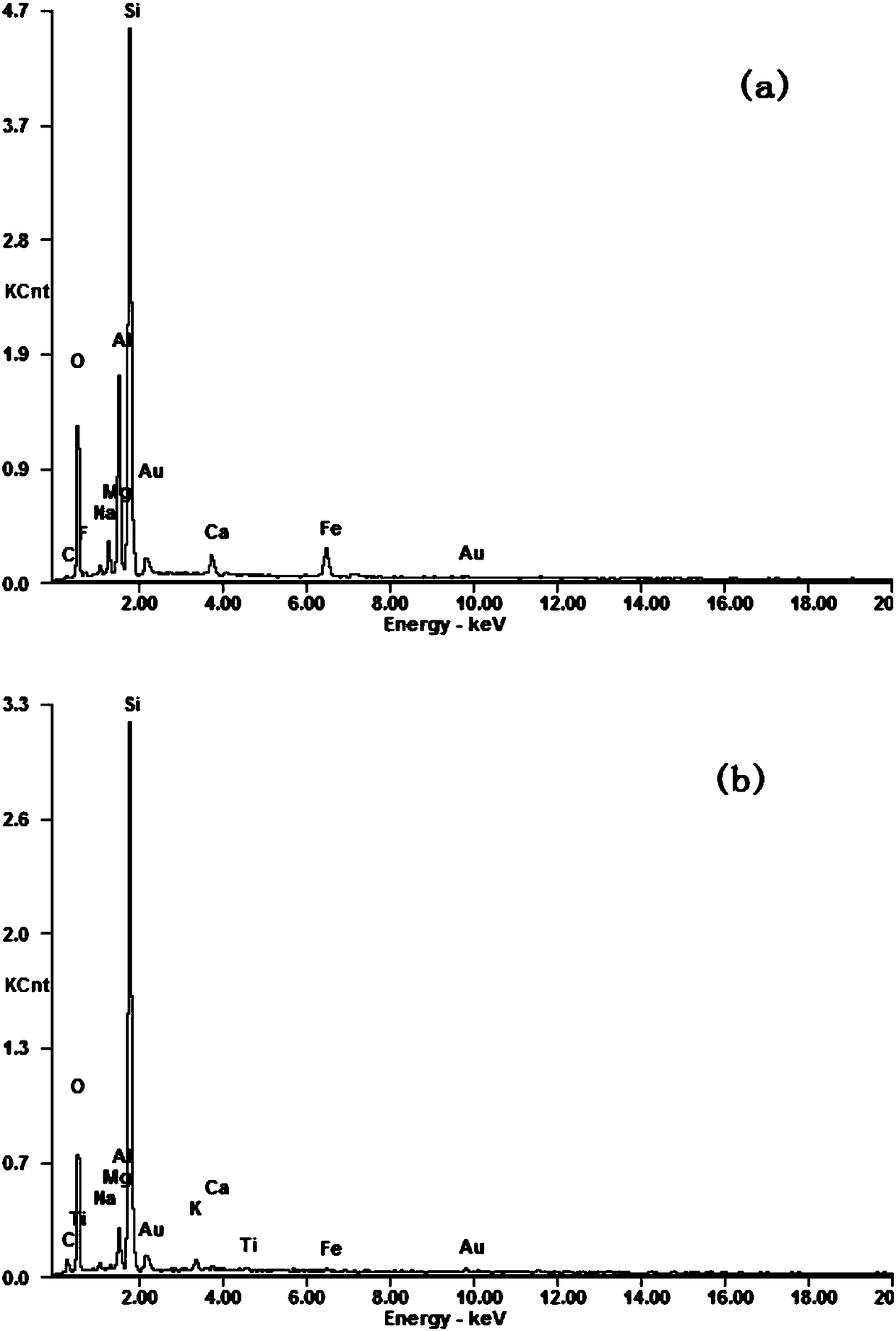

[0041] In this example, the mesoporous bentonite includes silicon oxide, aluminum oxide, and magnesium oxide, and is a layered clay mineral with a particle size of 1 μm to 20 μm, an average pore diameter of 5.531 nm, and a specific surface area of 244.622 m 2 / g.

[0042] A kind of preparation method of the mesoporized bentonite in the above-mentioned present embodiment, comprises the following steps:

[0043] (1) Solution preparation:

[0044] Weigh 120g NaOH into a beaker, add an appropriate amount of ultrapure water to dissolve it, transfer it to a 500mL volumetric flask, dilute to the mark with ultrapure water, and shake well to obtain a NaOH solution with a concentration of 6M (6mol / L).

[0045] Take 207.25mL of concentrated hydrochloric acid into a beaker containing an appropriate amount of ultrapure water, stir evenly, transfer ...

Embodiment 2

[0071] Investigate the effect of different mesoporous materials on the immobilization effect of laccase, including the following steps:

[0072] (1) Preparation of the solution:

[0073] Phosphate buffered saline solution (PBS) that preparation pH is 7.0: Take by weighing 35.814g disodium hydrogen phosphate (Na 2 HPO 4 12H 2 (0), after dissolving with deionized water, move into the 500ml volumetric flask to be constant volume for subsequent use, obtain the disodium hydrogen phosphate solution that concentration is 0.2M. Weigh 15.601g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (0), after dissolving with deionized water, move into the 500ml volumetric flask to be constant volume for subsequent use, obtain concentration and be the sodium dihydrogen phosphate solution of 0.2M. The above-mentioned disodium hydrogen phosphate solution and sodium dihydrogen phosphate solution were mixed according to a certain ratio until the pH of the mixed solution was 7.0 to obtain a phosph...

Embodiment 3

[0083] Investigate the operation stability of the immobilized laccase with the mesoporous bentonite of the present invention as the carrier, the specific operation process is as follows:

[0084] At 30°C, the immobilized laccase was reacted with 0.5mM ABTS, washed three times with citrate buffer (concentration: 0.1M, pH value: 5), centrifuged to obtain the reacted immobilized laccase, and the immobilized laccase was determined. The enzyme activity of laccase; The above-mentioned operation is repeated 10 times, to measure the operation stability of immobilized laccase, the result is as follows: Figure 7 shown.

[0085] The immobilized laccase used above was prepared by the following method: using the mesoporous bentonite in Example 1 as a carrier, according to the solid-liquid ratio of 400mg: 100mL (that is, the mass volume ratio of the carrier to the laccase solution is 400mg: 100mL) , adding mesoporous bentonite to the laccase solution with an initial concentration of 2mg / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com