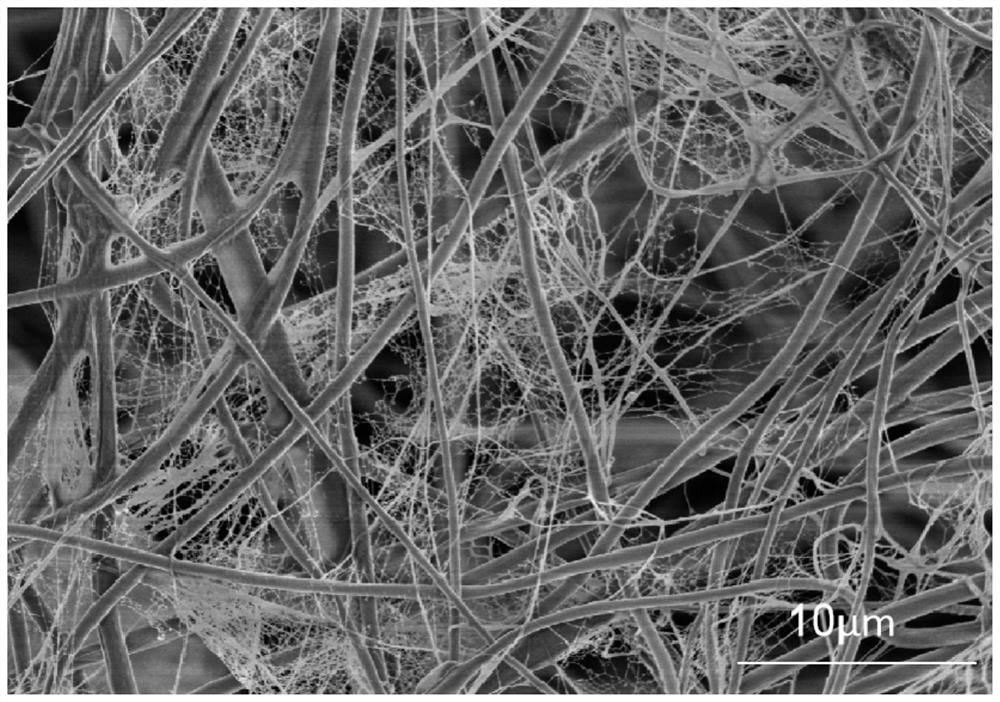

Preparation method of air filtering nanofiber membrane with dendritic multilevel structure

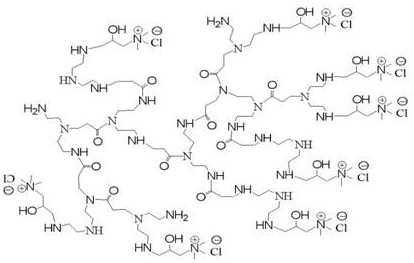

A nanofiber membrane and air filtration technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of single function of air filtration nanofiber membrane and low coverage of dendritic structure, and achieve improved splitting Excellent branching ability, remarkable bactericidal effect, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Take 8ml of dimethylacetamide and 2ml of acetone, and prepare a composite organic solvent system with a ratio of 8:2; according to the mass concentration of 12%, weigh 1.3g of polyvinylidene fluoride (PVDF) and add it to the composite In an organic solvent, and at a water bath temperature of 80°C, stir magnetically for 3 hours to obtain a colorless and transparent spinning solution; take 0.32g of amino-terminated hyperbranched compound quaternary ammonium salt (HBP-HTC) and add polyvinylidene fluoride (PVDF) for spinning In the liquid, under the temperature of 80 ℃ water bath, magnetically stir for 5 hours to obtain a homogeneous spinning solution; the spinning solution is left to stand for 1 hour to defoam. Under the conditions of 25cm, ambient temperature 30°C, and ambient humidity 30%, electrospinning is performed to obtain an air-filtering nanofiber membrane with good filtering effect, high-efficiency antibacterial, and rich dendritic multi-level structure...

Embodiment 2

[0043] Example 2: Take 7ml of dimethylacetamide and 3ml of acetone, and prepare a composite organic solvent system with a ratio of 7:3; according to the mass concentration of 10%, weigh 1.0g of polyvinylidene fluoride (PVDF) and add it to the composite In an organic solvent, and at a water bath temperature of 80°C, stir magnetically for 3 hours to obtain a colorless and transparent spinning solution; take 0.28g of amino-terminated hyperbranched compound quaternary ammonium salt (HBP-HTC) and add polyvinylidene fluoride (PVDF) for spinning In the liquid, under the temperature of 80 ℃ water bath, magnetically stir for 5 hours to obtain a homogeneous spinning solution; the spinning solution is left to stand for 1 hour to defoam. Under the conditions of 20cm, ambient temperature 30°C, and ambient humidity 30%, electrospinning is performed to obtain an air-filtering nanofiber membrane with good filtering effect, high-efficiency antibacterial, and rich dendritic multi-level structure...

Embodiment 3

[0044] Example 3: Take 8ml of dimethylacetamide and 2ml of acetone, and prepare a composite organic solvent system with a ratio of 8:2; according to the mass concentration of 12%, weigh 1.3g of polyvinylidene fluoride (PVDF) and add it to the composite In an organic solvent, and at 80 °C water bath temperature, magnetically stirred for 3 hours to obtain a colorless and transparent polyvinylidene fluoride spinning solution; take 0.28g of amino-terminated hyperbranched compound quaternary ammonium salt (HBP-HTC) and add polyvinylidene fluoride ( PVDF) spinning solution, at 80°C water bath temperature, magnetically stirred for 5 hours to obtain a homogeneous spinning solution; h. The receiving distance is 20cm, the ambient temperature is 30°C, and the ambient humidity is 30%, and electrospinning is carried out to obtain an air filtration nanofiber membrane with good filtering effect, high-efficiency antibacterial, and rich dendritic multi-level structure. . The coverage rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com