Infrared coating compatible with radar stealth and preparation method thereof

A radar stealth and infrared coating technology, which is applied in coatings, fireproof coatings, camouflage coatings, etc., can solve the problems of poor equipment shape matching, reduced radar stealth performance, and complicated processing technology, so as to achieve good equipment shape matching and improve Comprehensive stealth performance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

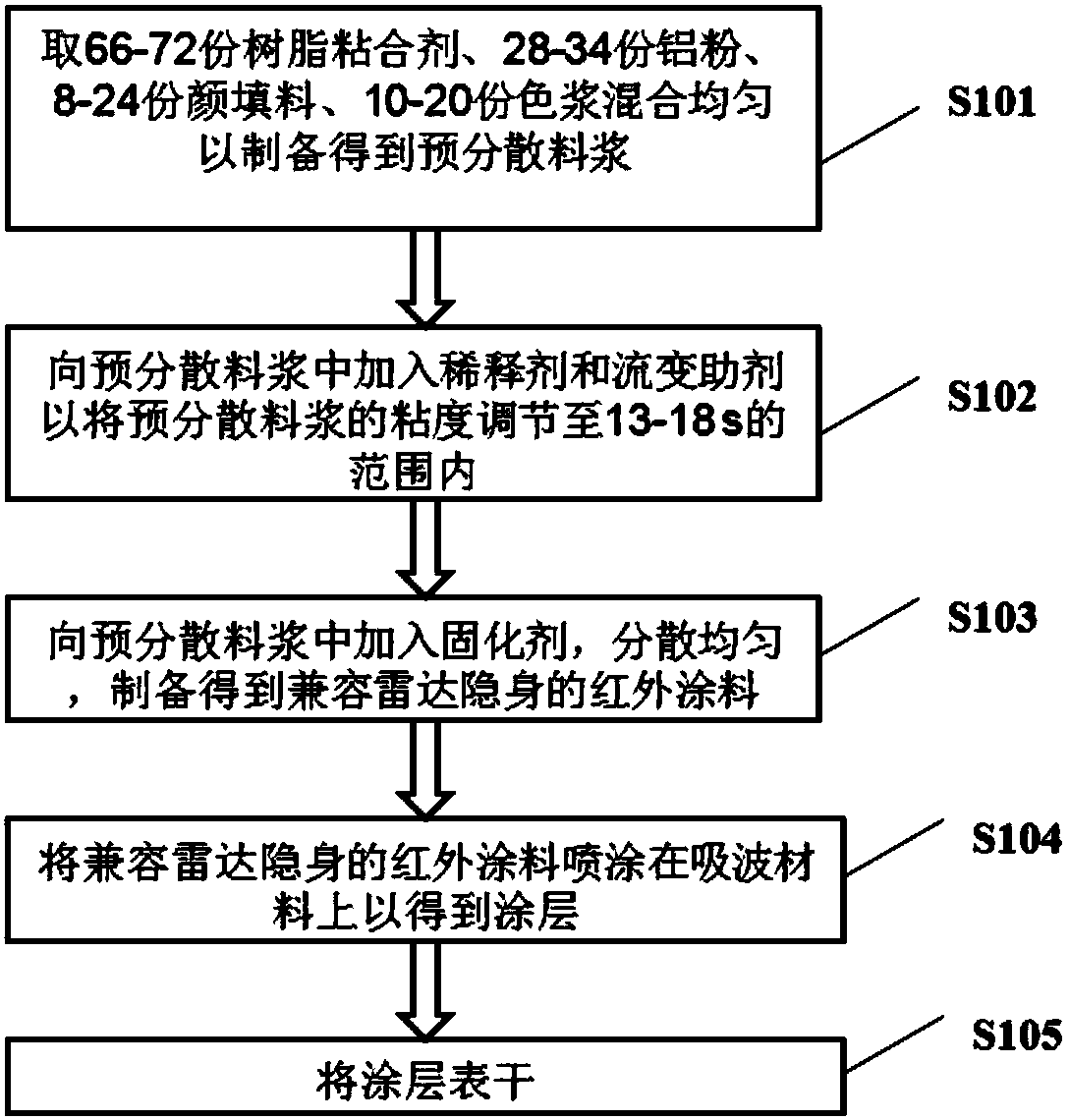

[0023] The preparation method of the temperature-resistant infrared low emissivity coating provided by the invention comprises the following steps:

[0024] Such as figure 1 As shown in step S101, take 66-72 parts of resin binder, 28-34 parts of aluminum powder, 8-24 parts of pigments and fillers, and 10-20 parts of color paste and mix them evenly to prepare pre-dispersed slurry. The high-speed disperser stirs at 200-450rpm for 0.4-0.8h to implement the mixing of resin binder, aluminum powder, pigments and fillers and color paste. Preferably, weigh 68 parts of resin binder, 27 parts of aluminum powder, 16 parts of pigment and filler, and 15 parts of color paste, stir with a high-speed disperser at 300 rpm for 0.6 h, and add diluent while stirring. Among them, the pigments and fillers are low-dielectric pigments and fillers with a low dielectric constant, such as low-dielectric pigments and fillers with a dielectric constant less than 3.0, and the resin binder is polyurethane,...

Embodiment 1

[0033] 1. Weigh 66 parts of resin binder polyurethane, add 34 parts of aluminum powder, add 8 parts of low-dielectric pigment filler polytetrafluoroethylene, add 15 parts of blue (or green or yellow or black color paste) , use a high-speed disperser to stir at 450rpm for 0.4h, and add an appropriate amount of diluent ethyl acetate while stirring;

[0034] 2. Put the stirred pre-dispersed slurry at room temperature for 24 hours, or put it into a ball mill tank (the diameter of the grinding beads is greater than 8mm) and mill it on a planetary ball mill at 20rpm with variable speed for 8 hours, then let it stand for 1 hour;

[0035] 3. Properly dilute the pre-dispersed slurry, put it into a laboratory sand mill for grinding (the diameter of the grinding medium is greater than 0.8mm), and put it into the mixing tank after grinding for 0.4h;

[0036] 4. Add the appropriate diluent ethyl acetate to the ground material and stir it with a high-speed disperser at a speed of 450rpm. Duri...

Embodiment 2

[0042] 1. Weigh 72 parts of resin binder polyurethane, add 34 parts of aluminum powder, add 24 parts of low-dielectric pigment filler polyimide, add 20 parts of green color paste, and stir at 200rpm with a high-speed disperser 0.8h, while stirring, add an appropriate amount of diluent butyl acetate;

[0043] 2. Put the stirred pre-dispersed slurry at room temperature for 48 hours, or put it into a ball mill tank (the diameter of the grinding beads is greater than 8mm) and mill it on a planetary ball mill at 60rpm with variable speed for 8 hours, then let it stand for 3 hours;

[0044] 3. Properly dilute the pre-dispersed slurry, put it into a laboratory sand mill for grinding (the diameter of the grinding medium is greater than 0.8mm), and put it into the mixing tank after grinding for 0.3h;

[0045] 4. Add the appropriate diluent butyl acetate to the ground material and stir it with a high-speed disperser at a speed of 400rpm. During the stirring process, add an appropriate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com