Preparation process of honey powder

A preparation process and technology of honey powder, which is used in food processing, food forming, food ingredients as anti-caking agents, etc. The effect of low rate and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

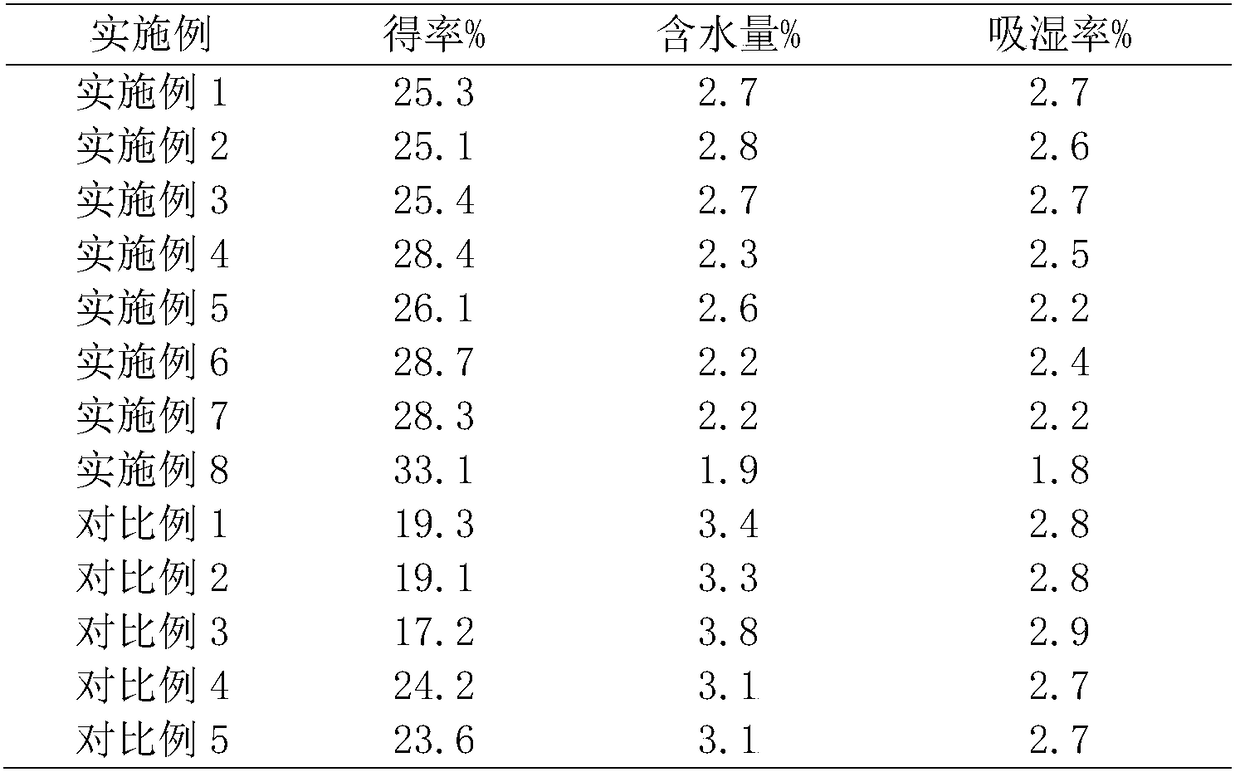

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation technology of honey powder, comprises the following steps, step 1, allocates feed liquid, takes by weighing 10kg maltodextrin, 1kgβ-cyclodextrin, 1kg gelatin, 5kg soluble soybean polysaccharide, after adding water and mixing, and then Add 80kg of honey, mix evenly, add water to adjust the solid content to 20%, and obtain a feed liquid.

[0025] Step 2, homogenization, the temperature of the feed liquid is controlled between 30-40° C., and the homogenization is carried out under a homogenization pressure of 20 MPa.

[0026] Step 3, spray drying, spray drying the homogenized feed liquid, the gas pressure is 0.1MPa, the inlet air temperature is 190°C, the outlet air temperature is 80°C, and the feed rate is 6ml / s to obtain honey powder.

Embodiment 2

[0027] Embodiment 2: a kind of preparation technology of honey powder, comprises the following steps, step 1, allocates material liquid, takes by weighing 13kg maltodextrin, 3kgβ-cyclodextrin, 2kg gelatin, 8kg soluble soybean polysaccharide, after adding water and mixing, then Add 95kg of honey, mix evenly, add water to adjust the solid content to 25%, and obtain a feed liquid.

[0028] Step 2, homogenization, the temperature of the feed liquid is controlled between 30-40° C., and the homogenization is carried out under a homogenization pressure of 20 MPa.

[0029] Step 3, spray drying, spray drying the homogenized feed liquid, the gas pressure is 0.1MPa, the inlet air temperature is 170°C, the outlet air temperature is 70°C, and the feed rate is 8ml / s to obtain honey powder.

Embodiment 3

[0030] Embodiment 3: a kind of preparation technology of honey powder, comprises the following steps, step 1, allocates feed liquid, takes by weighing 12kg maltodextrin, 2kgβ-cyclodextrin, 2kg gelatin, 6kg soluble soybean polysaccharide, after adding water and mixing, and then Add 90kg of honey, mix evenly, add water to adjust the solid content to 30%, and obtain a feed liquid.

[0031] Step 2, homogenization, the temperature of the feed liquid is controlled between 30-40° C., and the homogenization is carried out under a homogenization pressure of 20 MPa.

[0032] Step 3, spray drying, spray drying the homogenized feed liquid, the gas pressure is 0.1 MPa, the inlet air temperature is 180°C, the outlet air temperature is 75°C, and the feed rate is 5ml / s to obtain honey powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com