Preparation method of graphite oxide/multiwalled carbon nanotube/polyvinyl alcohol composite aerogel absorbing material

A multi-walled carbon nanotube, ternary composite technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problem of low recycling rate, low adsorption rate, and high processing cost problem, to achieve the effect of high adsorption rate, easy operation and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

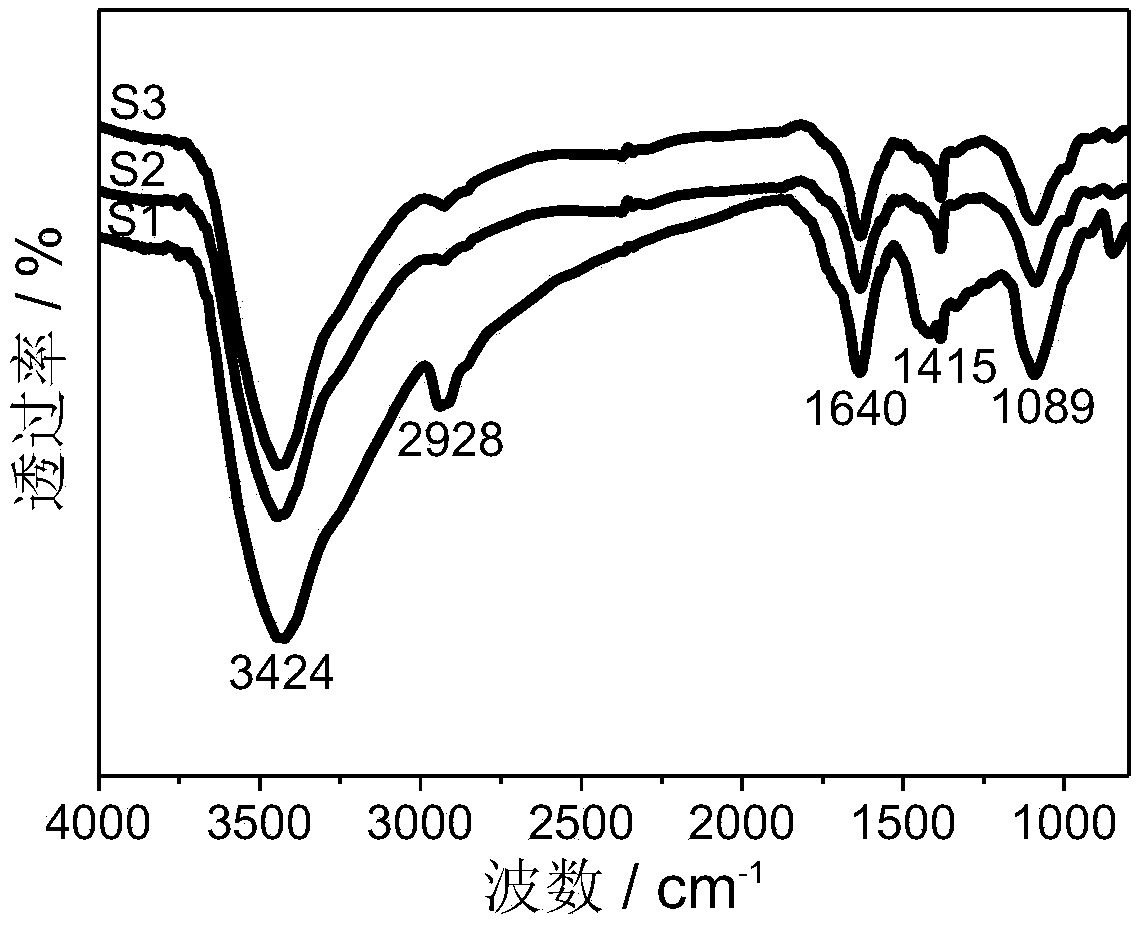

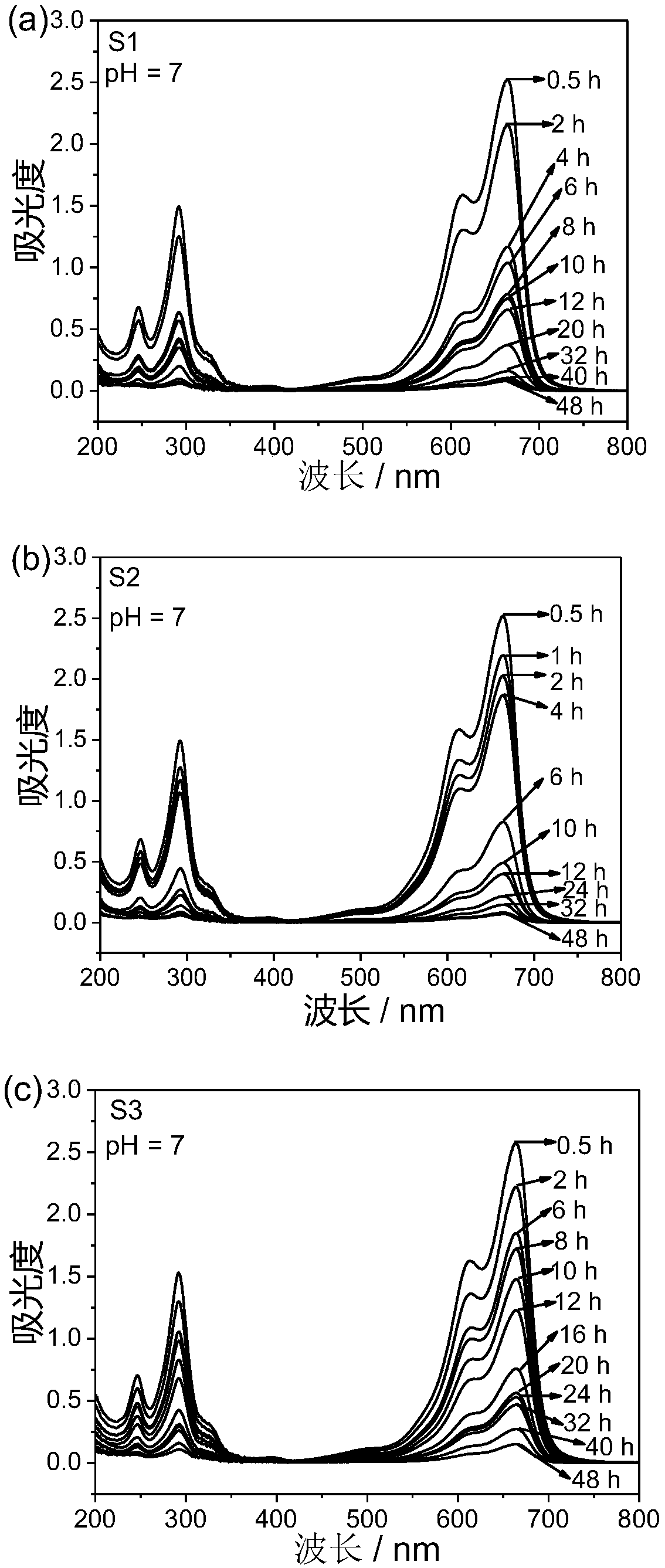

[0028] 1. Take three 50mL beakers, add 10mL deionized water, and then add 60mg graphite oxide respectively, sonicate for 30min, stir vigorously for 1.5h to obtain a graphene oxide (GO) aqueous dispersion with a concentration of 6mg / mL.

[0029] 2. Accurately weigh 1 g of polyvinyl alcohol (PVA) and add it to 99 mL of deionized water, stir vigorously at 95° C. for 5 h to dissolve completely, and cool to room temperature to obtain a PVA aqueous solution with a concentration of 1 wt%.

[0030] 3. Measure 10 mL of the PVA aqueous solution with a concentration of 1 wt% obtained in step (2), add it to the GO aqueous dispersion obtained in step (1), and stir at room temperature for 24 hours until uniformly mixed.

[0031] 4. Transfer the reaction solution to a long glass tube with an inner diameter of 2 cm and a volume of 30 mL, seal it with plastic wrap, freeze it in a refrigerator at -18°C for 20 hours, and then thaw it at room temperature for 4 hours. Repeat this cycle for 3 times ...

Embodiment 2

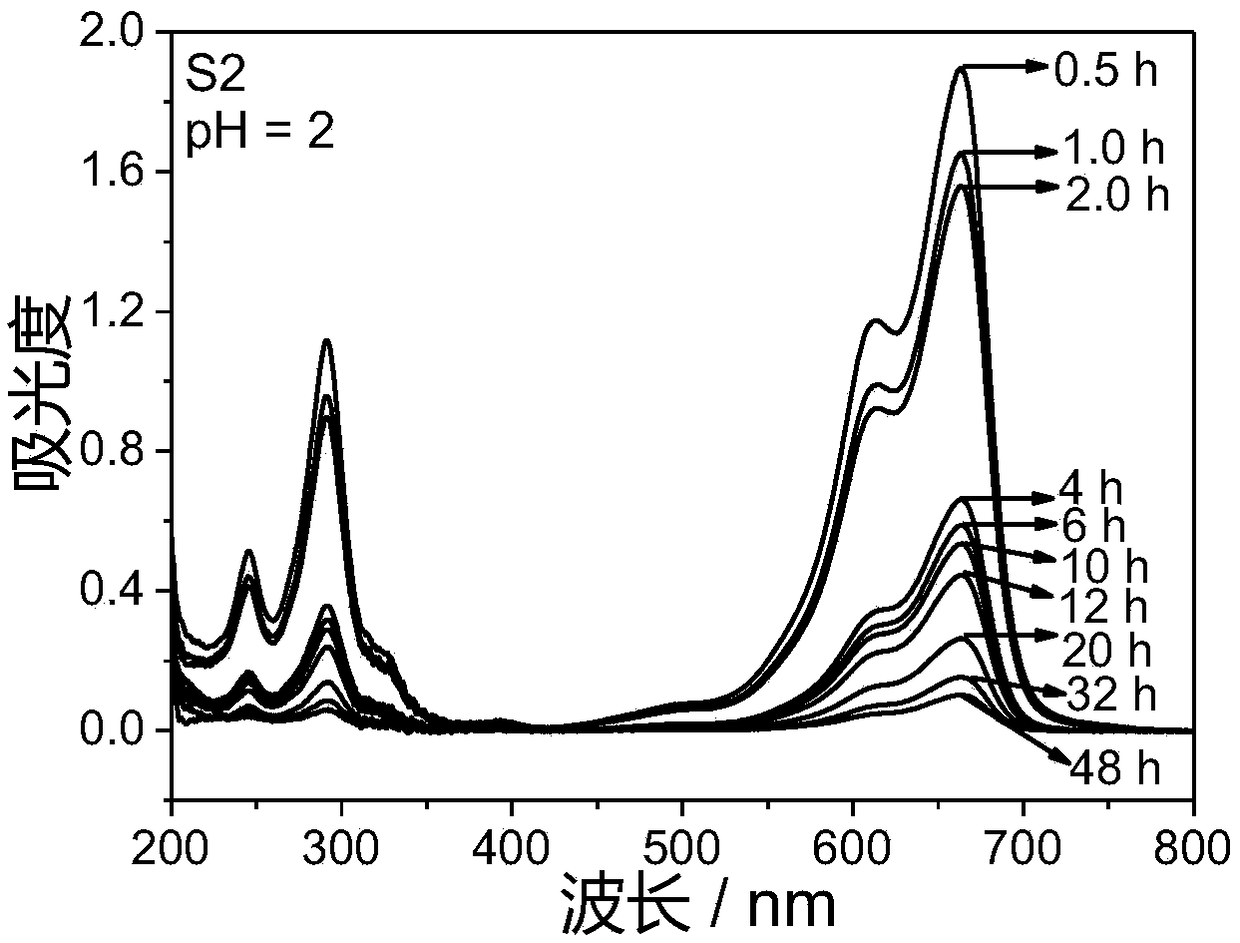

[0035] 1. Take three 50mL beakers, add 10mL deionized water respectively, then add 60mg graphite oxide respectively, ultrasonicate for 30min, stir vigorously for 1.5h to obtain a graphene oxide (GO) aqueous dispersion with a concentration of 6mg / mL, and then add 5mg of graphite oxide Multi-walled carbon nanotubes (MWCNTs) were uniformly dispersed in the GO dispersion by ultrasonication for 30 min to obtain a GO / MWCNTs aqueous dispersion.

[0036] 2. Accurately weigh 1 g of polyvinyl alcohol (PVA) and add it to 99 mL of deionized water, stir vigorously at 95° C. for 5 h to dissolve completely, and cool to room temperature to obtain a PVA aqueous solution with a concentration of 1 wt%.

[0037] 3. Measure 10 mL of the PVA aqueous solution with a concentration of 1 wt% obtained in step (2), add it to the GO / MWCNTs aqueous dispersion obtained in step (1), and stir at room temperature for 24 hours until uniformly mixed.

[0038] 4. Transfer the reaction solution to a long glass tub...

Embodiment 3

[0042] 1. Take three 50mL beakers, add 10mL deionized water respectively, then add 60mg graphite oxide respectively, ultrasonicate for 30min, stir vigorously for 1.5h to obtain a graphene oxide (GO) aqueous dispersion with a concentration of 6mg / mL, and then add 10mg of graphite oxide Multi-walled carbon nanotubes (MWCNTs) were uniformly dispersed in the GO dispersion by ultrasonication for 30 min to obtain a GO / MWCNTs aqueous dispersion.

[0043] 2. Accurately weigh 1 g of polyvinyl alcohol (PVA) and add it to 99 mL of deionized water, stir vigorously at 95° C. for 5 h to dissolve completely, and cool to room temperature to obtain a PVA aqueous solution with a concentration of 1 wt%.

[0044] 3. Measure 10 mL of the PVA aqueous solution with a concentration of 1 wt% obtained in step (2), add it to the GO / MWCNTs aqueous dispersion obtained in step (1), and stir at room temperature for 24 hours until uniformly mixed.

[0045] 4. Transfer the reaction solution to a long glass tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com