Bioactive glass, bioactive glass gel and preparation method and application thereof

A technology of bioactive glass and gel, which is applied in drug combination, drug delivery, and pharmaceutical formulations, and can solve problems such as poor curative effect and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

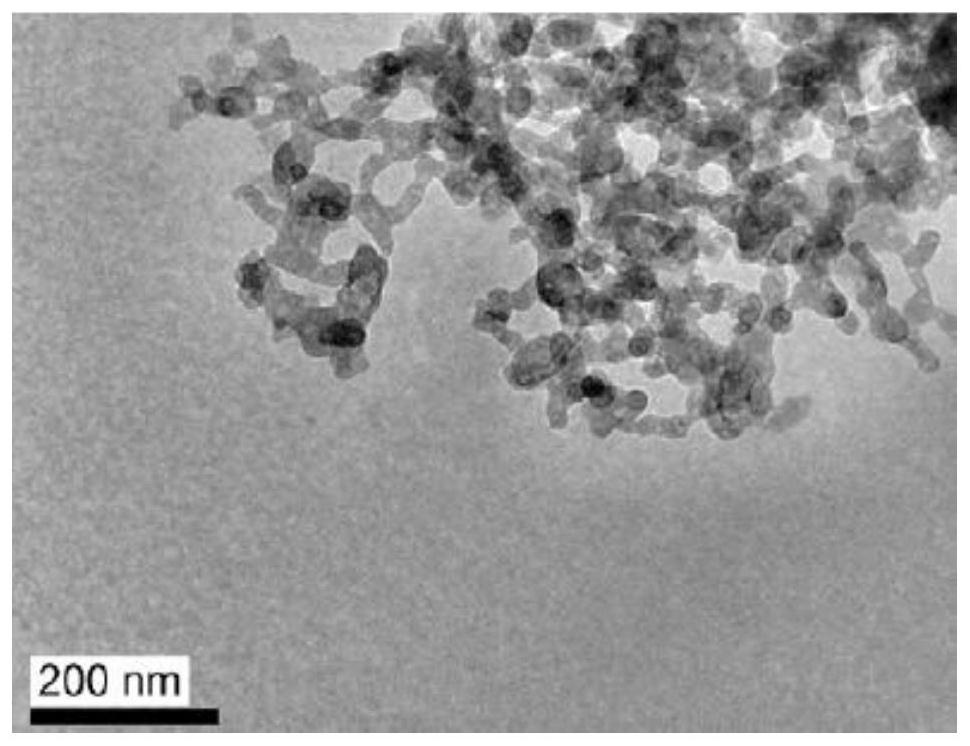

Image

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of bioactive glass, comprises the following steps:

[0036] S1, add silica gel, sodium nitrate, triethyl phosphate, calcium nitrate tetrahydrate and templating agent to hydrochloric acid aqueous solution (dilute 1-3mol / L hydrochloric acid solution to 0.05mol / L-0.2mol / L with deionized water) placed in 60°C at a speed of 300r / min and stirred for 4h to obtain a sol. Wherein, the molar ratio of silica gel, sodium nitrate, triethyl phosphate and calcium nitrate tetrahydrate is 60.1%:17.2%:19.3%:3.4%, and the mass percentage of template agent in the total mass of raw materials is 0.5%. The templating agent is polyethylene glycol 400. S2, aging the sol obtained in step S1 in an environment of 60° C. for 6 hours to obtain a wet gel.

[0037] S3, drying the wet gel obtained in step S2 in an environment of 105° C. for 6 hours to obtain a dry gel.

[0038] S4, placing the xerogel obtained in step S3 in an environment ...

Embodiment 2

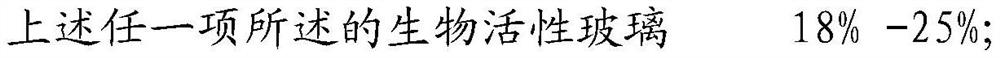

[0045] This embodiment provides a bioactive glass gel, which is mainly composed of the following components in weight percentage, as shown in Table 1 below:

[0046] The composition table of the bioactive glass gel of table 1 embodiment 2

[0047]

[0048]

[0049] This embodiment also provides a preparation method of the bioactive glass gel, comprising the following steps:

[0050] S1, weigh each component according to the composition of the bioactive glass gel in Table 1.

[0051] S2, preprocessing:

[0052] Place the bioactive glass in an environment of 120±5°C for vacuum drying, heat and melt the medical vaseline and medical paraffin at 70±10°C respectively, and filter through a 200-mesh sieve while hot to remove impurities.

[0053] S3, put the heated and melted medical vaseline in a single-necked flask, heat and stir at 250r / min at 70±10°C, absorb the heated and melted medical paraffin with a syringe, and slowly inject it into the melted For medical vaseline, keep...

Embodiment 3

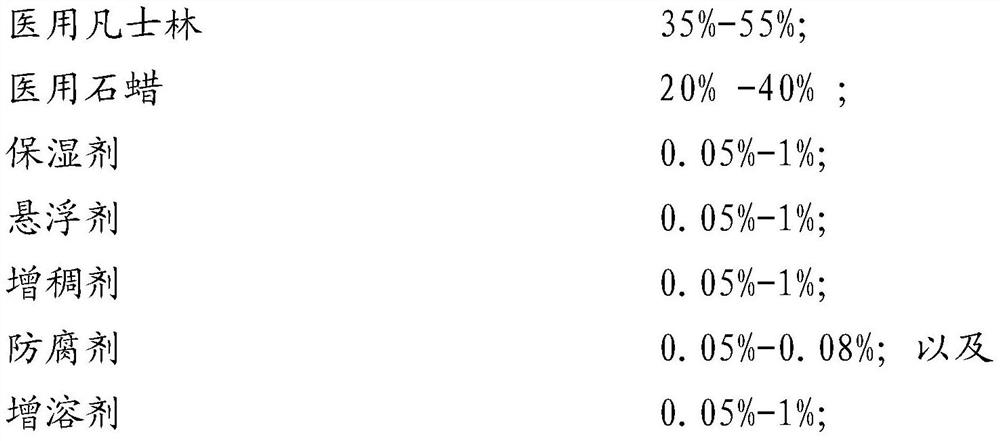

[0055] This embodiment provides a bioactive glass gel, which is mainly composed of the following components by weight percentage, as shown in Table 2 below:

[0056] The composition table of the bioactive glass gel of table 2 embodiment 3

[0057]

[0058]

[0059] This embodiment also provides a preparation method of the bioactive glass gel, comprising the following steps:

[0060] S1, weigh each component according to the composition of the bioactive glass gel in Table 2.

[0061] S2, preprocessing:

[0062] Place the bioactive glass in an environment of 120±5°C for vacuum drying, heat and melt the medical vaseline and medical paraffin at 70±10°C respectively, and filter through a 200-mesh sieve while hot to remove impurities.

[0063] S3, put the heated and melted medical vaseline in a single-necked flask, heat and stir at 150r / min at 70±10°C, absorb the heated and melted medical paraffin with a syringe, and slowly inject it into the melted For medical vaseline, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com