Antibacterial ceramic product and preparation method thereof

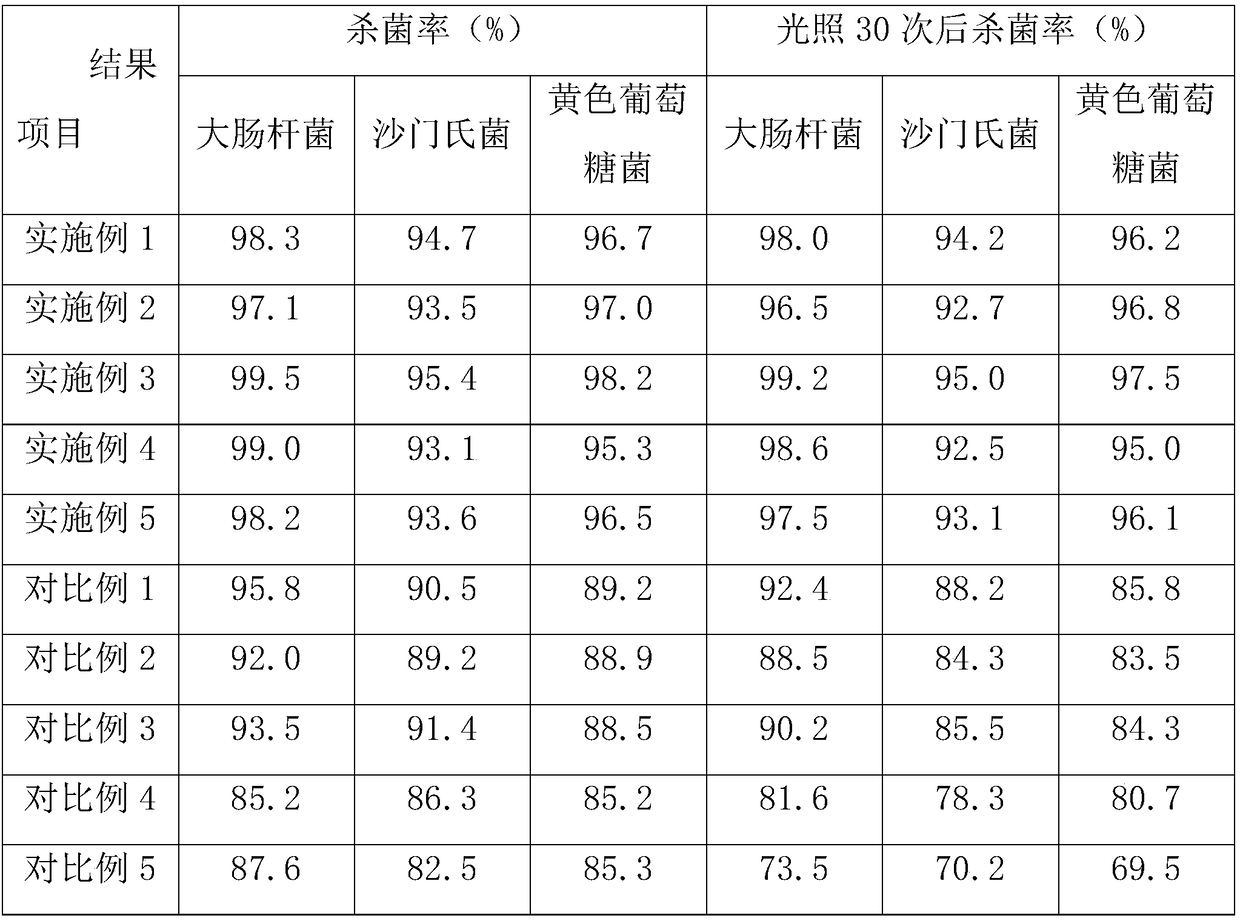

A technology of antibacterial ceramics and products, applied in the field of ceramics, can solve the problems of antibacterial film and ceramics easy to fall off, poor antibacterial effect, silver ion volatilization, etc., achieve significant antibacterial and bactericidal effects, realize waste utilization, and improve plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An antibacterial ceramic product comprises the following raw material components in parts by weight: 25 parts of coal gangue, 15 parts of sea mud, 10 parts of shell powder, 3 parts of boron mud, 10 parts of ceramic clay, and 10 parts of potassium feldspar.

[0023] The preparation method of this antibacterial ceramic product comprises the following steps:

[0024] S1. Take each raw material component according to the above parts by weight, mix and pulverize it and pass through a 100-mesh sieve to obtain a powder;

[0025] S2. Add distilled water twice the total weight of the powder to the powder, ultrasonically disperse at room temperature, and then pour it into a ball mill for ball milling. The ball milling speed is 200r / min, and the time is 4h; then pass through a 300-mesh sieve to obtain a slurry ;

[0026] S3, the slurry is sprayed and granulated, and dry-pressed to form a green body;

[0027] S4. Dry the green body, and then fire the dried green body; the firing ...

Embodiment 2

[0029] An antibacterial ceramic product, comprising the following raw material components in parts by weight: 18 parts of coal gangue, 19 parts of sea mud, 12 parts of shell powder, 5 parts of boron mud, 14 parts of ceramic clay, 12 parts of potassium feldspar, and 1 part of vanadium yellow material share.

[0030] The preparation method of this antibacterial ceramic product comprises the following steps:

[0031] S1. Take each raw material component according to the above parts by weight, mix and pulverize it and pass through a 170-mesh sieve to obtain a powder;

[0032] S2. Add distilled water 3 times the total weight of the powder to the powder, ultrasonically disperse at room temperature, and then pour it into a ball mill for ball milling. The ball milling speed is 200r / min, and the time is 5h; then pass through a 325-mesh sieve to obtain a slurry ;

[0033] S3, the slurry is press-filtered and smelted, and extruded to form a green body;

[0034] S4. Dry the green body,...

Embodiment 3

[0036] An antibacterial ceramic product comprises the following raw material components in parts by weight: 30 parts of coal gangue after removal of impurities, 18 parts of sea mud, 13 parts of shell powder, 6 parts of boron mud, 15 parts of ceramic clay, and 12 parts of potassium feldspar.

[0037] The preparation method of this antibacterial ceramic product comprises the following steps:

[0038] S1. Take each raw material component according to the above parts by weight, mix and pulverize it and pass through a 150-mesh sieve to obtain a powder;

[0039] S2. Add distilled water 3 times the total weight of the powder to the powder, ultrasonically disperse at room temperature, and then pour it into a ball mill for ball milling. The ball milling speed is 220r / min, and the time is 6h; then pass through a 325-mesh sieve to obtain a slurry ;

[0040] S3, the slurry is press-filtered and smelted, and extruded to form a green body;

[0041] S4. Dry the green body, and then fire th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com