Preparation method of H-MOF-5/TCPP fluorescent composite material

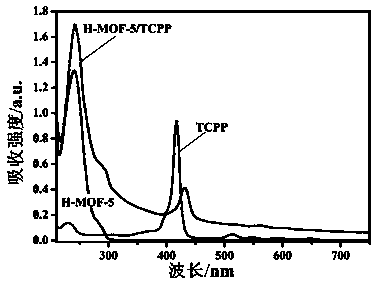

An H-MOF-5, composite material technology, applied in the field of quantum chemistry, can solve the problems of composite material morphology influence, easy generation of by-products, optical property inhibition, etc., to improve water solubility and fluorescence properties, prevent aggregation, and maintain The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

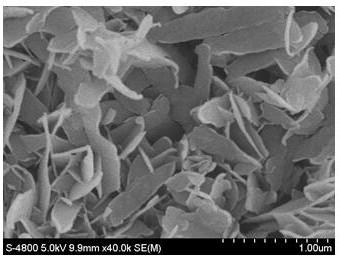

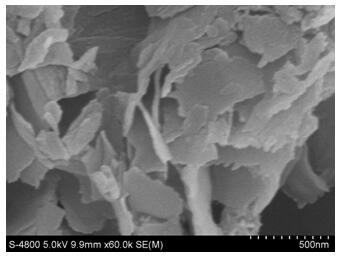

[0021] Weigh 70 mg of zinc nitrate, 17 mg of terephthalic acid, 40 mg of N-polyvinylpyrrolidone and 20 mg of dodecanoic acid, dissolve them in 5 mL of N-N-dimethylacetamide, transfer them to a sealed autoclave, and Put the reaction kettle into an oven and react at a temperature of 120°C for 30 minutes. After cooling down to room temperature, centrifuge at 10,000 rpm for 10 minutes, wash with ethanol three times, put it in a vacuum oven at 50°C, and dry for 3 hours to obtain H-MOF-5 nanosheets . Weigh 0.036g of the H-MOF-5 nanosheets, dissolve in 5mL ethanol solution, and ultrasonically treat for 10min to obtain a mixed solution; under stirring conditions, add 0.01g of porphyrin to the mixed solution, and stir to make the porphyrin completely Dissolve and continue to stir for 8 hours at room temperature to obtain a mixture; centrifuge at 10,000 rpm for 5 minutes to separate the product, wash with ethanol three times and centrifuge, and dry in a vacuum oven at 50°C for 3 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com