High-performance waterborne glass wine bottle coating and preparation method thereof

A high-performance, water-based technology, applied in the direction of coating, etc., can solve the problems that water-based glass wine bottle coating products have not been successfully developed, cannot meet the construction requirements of water-based coatings, and the baking time can only reach 20 minutes. Ultra-low VOC, improved production environment, fast drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

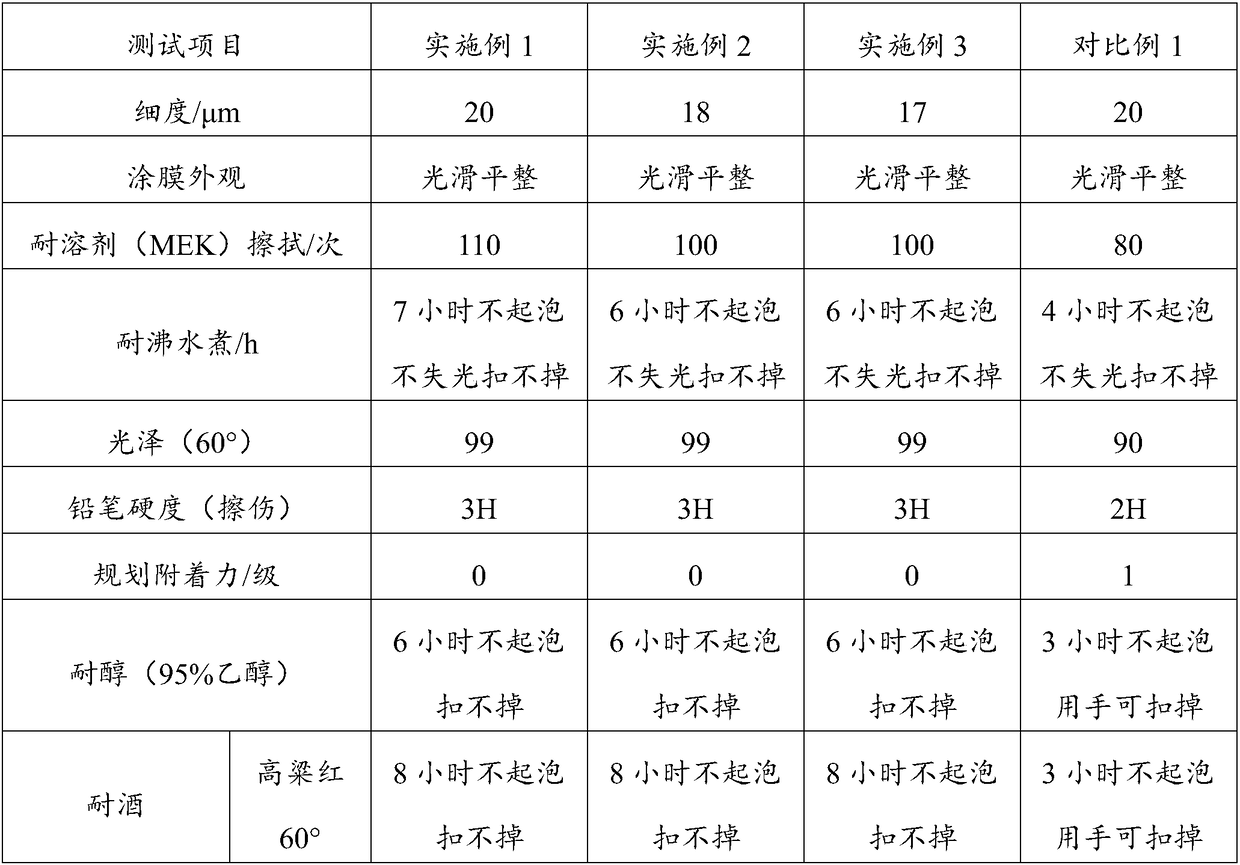

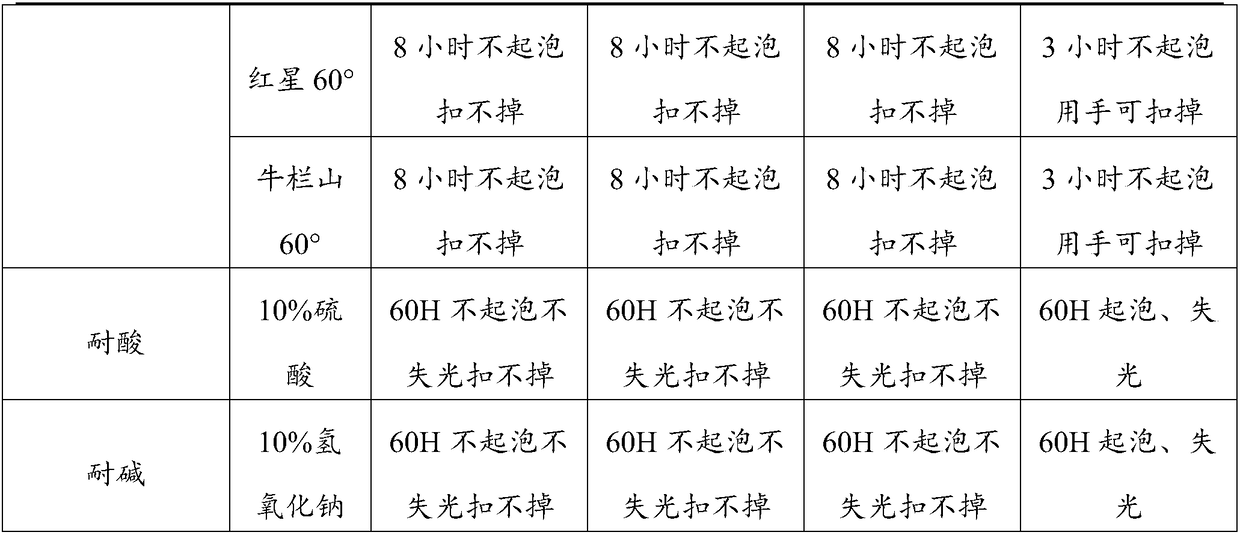

Examples

Embodiment 1

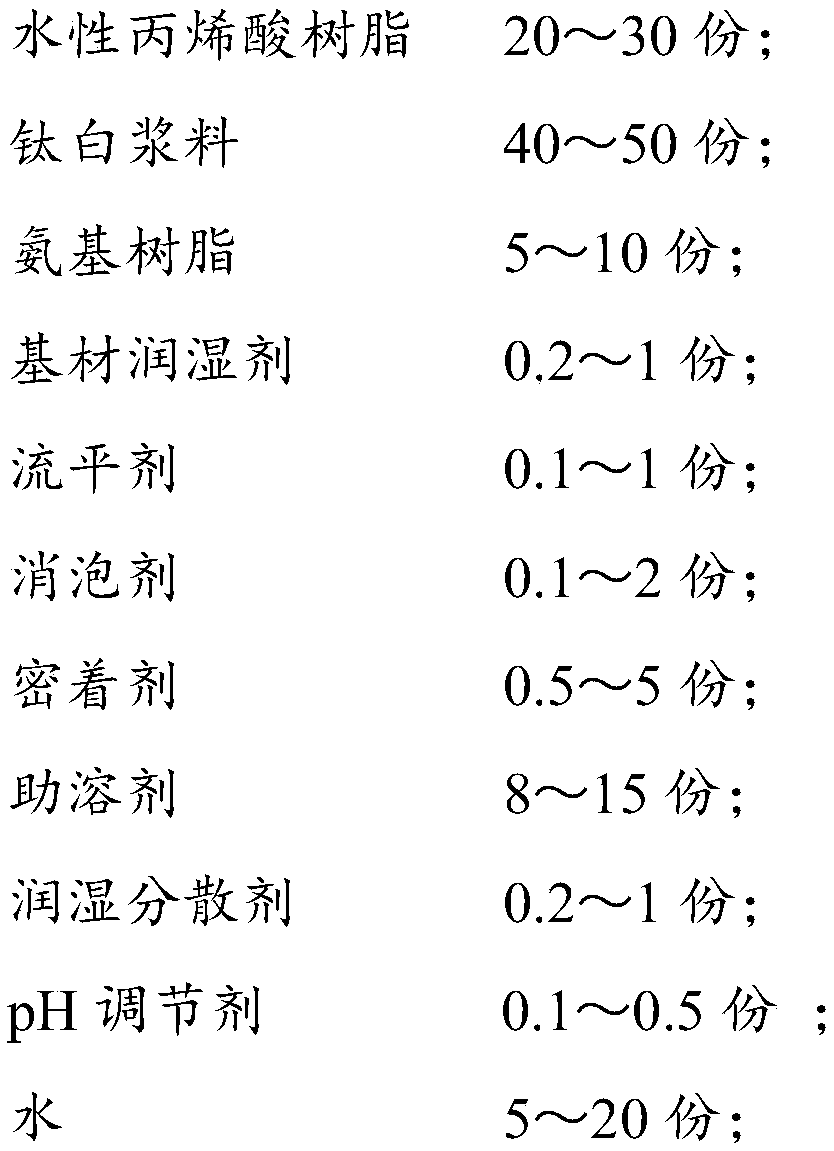

[0041] A kind of high-performance water-based glass wine bottle coating, its component is as follows:

[0042] Component A:

[0043] 25 parts of water-based acrylic resin;

[0044] 45 parts of titanium dioxide slurry;

[0045] 10 parts of amino resin;

[0046] 0.25 parts of substrate wetting agent;

[0047] Leveling agent 0.2 part;

[0048] 0.15 part of defoamer;

[0049] Adhesive 1 part;

[0050] Wetting and dispersing agent 0.3 parts;

[0051] 3 parts of ethylene glycol monobutyl ether;

[0052] 2.2 parts of n-butanol;

[0053] 3 parts of ethanol;

[0054] 9.6 parts of deionized water;

[0055] 0.3 part of pH regulator;

[0056] Component B:

[0057] 3 parts of silane coupling agent.

[0058]More specifically, in this embodiment, the water-based acrylic resin is HOMAPE5201 from Jintuan Chemicals Co., Ltd.; the leveling agent is polyether siloxane; the precipitating agent is polyamide wax; the substrate wetting agent is polysiloxane- The polyether copolymer come...

Embodiment 2

[0066] A kind of high-performance water-based glass wine bottle coating, its component is as follows:

[0067] Component A:

[0068] 22 parts of water-based acrylic resin;

[0069] 50 parts of titanium dioxide slurry;

[0070] 8 parts of amino resin;

[0071] Substrate wetting agent 0.25 part;

[0072] Leveling agent 0.2 part;

[0073] 0.15 part of defoamer;

[0074] Adhesive 2 parts;

[0075] Wetting and dispersing agent 0.3 parts;

[0076] 3 parts of ethylene glycol monobutyl ether;

[0077] 2.2 parts of n-butanol;

[0078] 5 parts of ethanol;

[0079] 6.6 parts of deionized water;

[0080] 0.3 part of pH regulator;

[0081] Component B:

[0082] 3 parts of silane coupling agent.

[0083] More specifically, the water-based acrylic resin described in this embodiment is Wanhua Chemical Antkote2366 water-soluble hydroxyacrylic resin; the leveling agent is polyether siloxane; the anti-settling agent is polyamide wax; The wetting agent described is a polysiloxane-po...

Embodiment 3

[0092] A kind of high-performance water-based glass wine bottle coating, its component is as follows:

[0093] Component A:

[0094] 28 parts of water-based acrylic resin;

[0095] 40 parts of titanium dioxide slurry;

[0096] 5 parts of amino resin;

[0097] Substrate wetting agent 0.2 part;

[0098] Leveling agent 0.5 parts;

[0099] 0.3 part of defoamer;

[0100] Adhesive 0.8 parts;

[0101] Wetting and dispersing agent 0.5 parts;

[0102] 4 parts of ethylene glycol monobutyl ether;

[0103] 3 parts of n-butanol;

[0104] 6 parts of ethanol;

[0105] 11.5 parts of deionized water;

[0106] 0.2 part of pH regulator;

[0107] Component B:

[0108] 2 parts of silane coupling agent.

[0109] More specifically, in this embodiment, the water-based acrylic resin is HOMAPE5201 from Jintuan Chemicals Co., Ltd.; the leveling agent is polyether siloxane; the precipitating agent is polyamide wax; the substrate wetting agent is polysiloxane- The polyether copolymer is from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com