Coated polyurea material and coated polyurea material plate and preparation method

A material board and polyurea technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of not being able to save a lot of expenses, not being able to withstand cycle heat, and poor low-temperature impact resistance, and achieve outstanding economic effects. The effect of arbitrary adjustment of appearance color and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

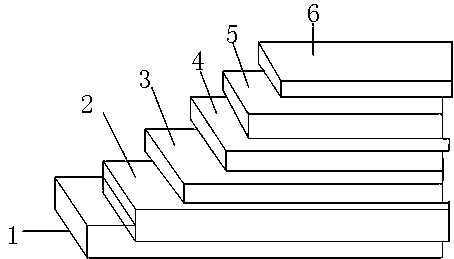

[0057] The foam sculpture itself is a fragile and fragile structure, which is attached to the base of the foam sculpture through an external coating structure to achieve the protection of the outer surface of impact resistance, wear resistance, rain resistance and weather resistance. No cracking, no delamination, impact resistance, aging resistance, UV resistance and other functions after being impacted by external forces.

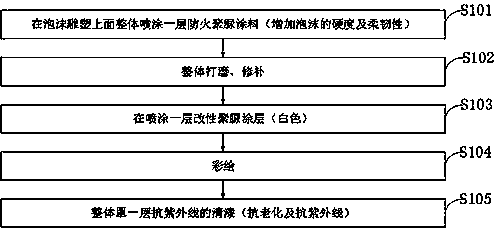

[0058] Specific construction plan:

[0059] step

design content

design needs materials

1

Grinding, repairing

2

Spray polyurea coating

Fireproof polyurea coating

3

overall grinding

4

Modified polyurea coating

Modified polyurea coating

5

painted coating

Paint

6

anti aging varnish

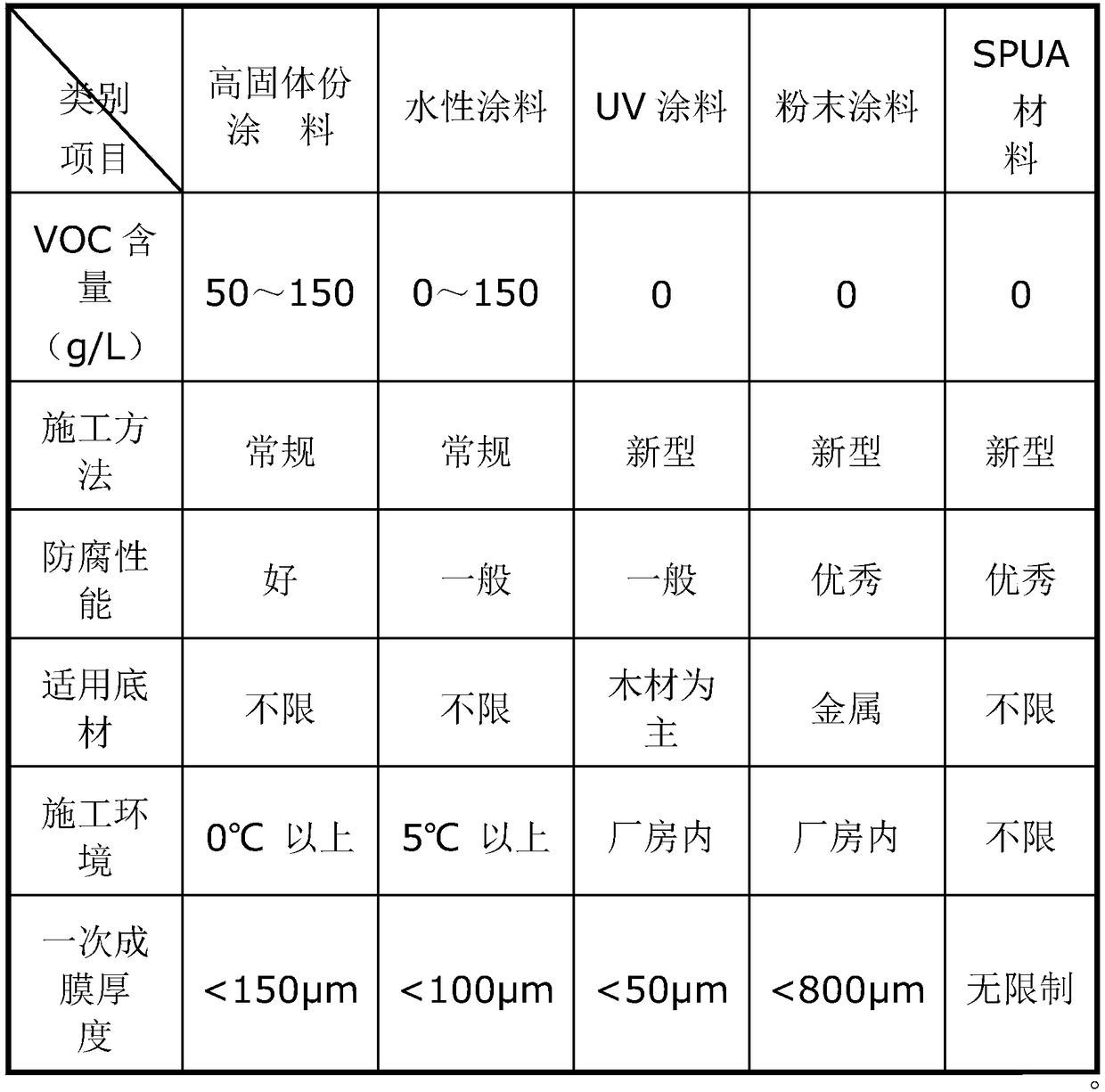

[0060] Advantages of the integral coating of the present invention:

[0061] The coating cures quickly and the production efficiency is high.

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com