Super-amphiphobic coating with seawater corrosion resistance and preparation process thereof

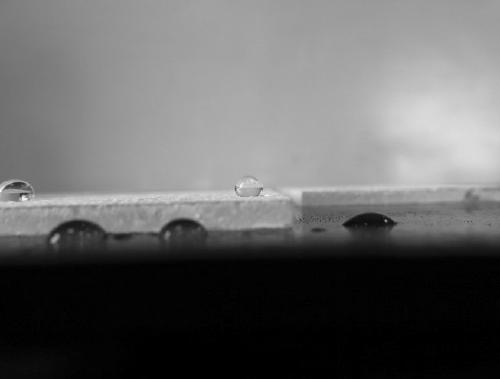

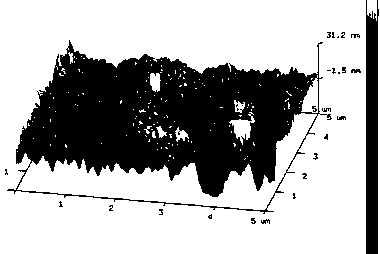

A corrosion-resistant coating and seawater-resistant technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as aging failure, poor stability, and damage to the surface microstructure, and achieve improved salt corrosion resistance and salt resistance. Corrosion improvement and salt corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation steps of the super-amphiphobic seawater corrosion-resistant coating are as follows:

[0034] (1) Stir the epoxy resin emulsion magnetically at a temperature of 60°C, the stirring rate is 1000r / min, the stirring time is 0.5h, and stand for 5h after stirring to fully open the resin molecular chain;

[0035] (2) Add n-butanol and N, N-dimethylacetamide to the epoxy resin emulsion obtained in step (1) to modify the epoxy resin emulsion to obtain a modified epoxy resin dilution emulsion, and then add fluorine Carbon resin, stirred for 1.5h at a stirring rate of 800r / min to obtain a resin mixture; the weight ratio of epoxy resin emulsion, n-butanol, N, N-dimethylacetamide and fluorocarbon resin is 10 :3:2:4.

[0036] (3) Mix the resin mixture obtained in step (2) with dimethyl silicone oil at a mass ratio of 1:5, then add methanol to dissolve into a jelly, and obtain a dispersion after ultrasonic dispersion for 10 minutes; the amount of methanol added is to f...

Embodiment 2

[0044] The preparation steps of the super-amphiphobic seawater corrosion-resistant coating are as follows:

[0045] (1) Magnetically stir the epoxy resin emulsion at a temperature of 80°C, the stirring rate is 1200r / min, the stirring time is 1.2h, and stand for 5h after stirring to fully open the resin molecular chain;

[0046] (2) Add n-butanol and N, N-dimethylacetamide to the epoxy resin emulsion obtained in step (1) to modify the epoxy resin emulsion to obtain a modified epoxy resin dilution emulsion, and then add fluorine Carbon resin, stirred for 2.5h at a stirring rate of 1100r / min to obtain a resin mixture; the weight ratio of epoxy resin emulsion, n-butanol, N, N-dimethylacetamide and fluorocarbon resin is 10 :3:2:4.

[0047] (3) Mix the resin mixture obtained in step (2) with simethicone at a mass ratio of 1:4, then add methanol to dissolve into a jelly, and obtain a dispersion after ultrasonic dispersion for 20 minutes; the amount of methanol added is to form Just...

Embodiment 3

[0055] The preparation steps of the super-amphiphobic seawater corrosion-resistant coating are as follows:

[0056] (1) Magnetically stir the epoxy resin emulsion at a temperature of 120°C, the stirring rate is 1400r / min, the stirring time is 2h, and stand for 5h after stirring to fully open the resin molecular chain;

[0057] (2) Add n-butanol and N, N-dimethylacetamide to the epoxy resin emulsion obtained in step (1) to modify the epoxy resin emulsion to obtain a modified epoxy resin dilution emulsion, and then add fluorine Carbon resin, stirred for 4h at a stirring rate of 1400r / min to obtain a resin mixture; the weight ratio of epoxy resin emulsion, n-butanol, N, N-dimethylacetamide and fluorocarbon resin is 10: 3:2:4.

[0058] (3) Mix the resin mixture obtained in step (2) with simethicone at a mass ratio of 1:5, then add methanol to dissolve into a jelly, and obtain a dispersion after ultrasonic dispersion for 25 minutes; the amount of methanol added is to form Just je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com