Phase-change expanded fireproof multi-component alkyd resin transparent primer and preparation method thereof

An alkyd resin, phase-change expansion technology, used in primers, fire-retardant coatings, coatings, etc., can solve the problems of opacity, can not be painted with the natural color of wood products, and primers do not have flame retardant and fire-resistant properties, and achieve decorative Good performance, win the opportunity of fire rescue and escape, and reduce the effect of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

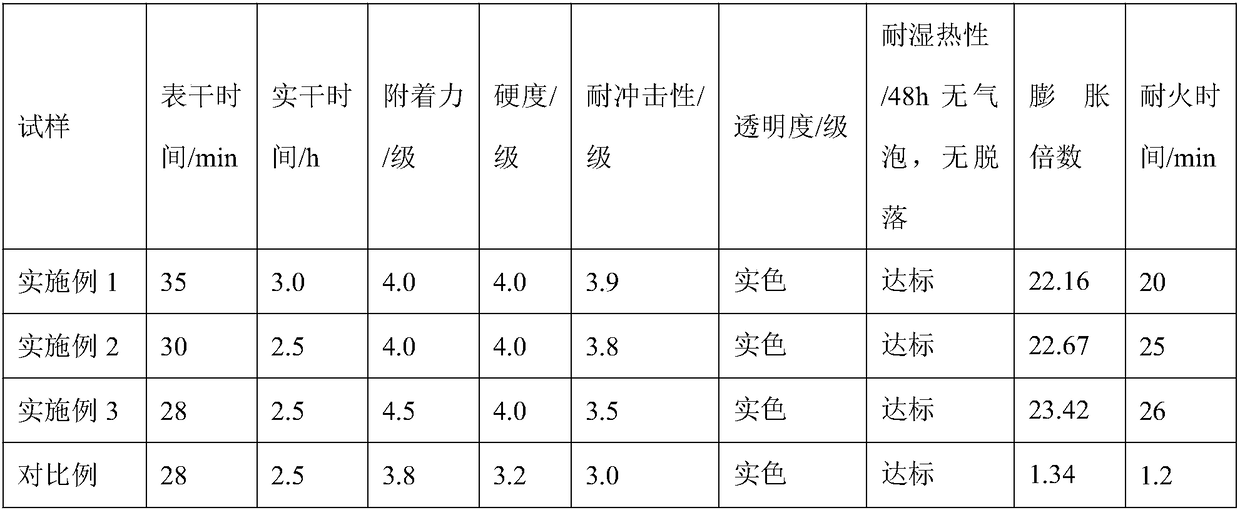

Examples

Embodiment 1

[0045] A kind of multi-component alkyd resin transparent primer of phase change expansion and fire prevention of the present invention, its preparation method comprises the steps:

[0046] (1) Preparation of starch phosphate: Dissolve 0.6g sodium dihydrogen phosphate, 1.0g disodium hydrogen phosphate, 1.6g hydrogen peroxide and 5.85g urea in 100g water to obtain a mixed solution, adjust to the required concentration with dilute acid or dilute alkali The pH is 5.0, then sprayed into 100g of starch under stirring, continue to stir for 30min, and raise the temperature to 65°C under low vacuum to oxidize and dry and dehydrate until the water content is about 10%, and the obtained product is stirred and heated on a fluidized bed dryer Phosphate reaction at 135°C for 1.0h, crush and sieve (160 mesh) to obtain starch phosphate ester. After testing, the degree of substitution DS of starch phosphate ester is 0.120, and the transparency of starch paste is 89.46%;

[0047] (2) Preparatio...

Embodiment 2

[0053] A kind of multi-component alkyd resin transparent primer of phase change expansion and fire prevention of the present invention, its preparation method comprises the steps:

[0054] (1) Preparation of starch phosphate: Dissolve 0.6 parts of sodium dihydrogen phosphate, 1.0 parts of disodium hydrogen phosphate, 1.6 parts of hydrogen peroxide and 5.85 parts of urea in 100 parts of water, and adjust to the required pH with dilute acid or dilute alkali. 5.0, then spray into 100 parts of starch under stirring, continue to stir for 30 minutes, heat up to 65°C under low vacuum, oxidize and dry and dehydrate until the water content is about 10%, stir and heat to 135°C on a fluidized bed dryer Phosphoric acid Esterification reaction for 1.0h, pulverization, sieving (160 mesh) to obtain starch phosphate ester, after testing, the degree of substitution DS of starch phosphate ester was 0.120, and the transparency of starch paste was 89.46%;

[0055](2) Preparation of phase change f...

Embodiment 3

[0061] A kind of multi-component alkyd resin transparent primer of phase change expansion and fire prevention of the present invention, its preparation method comprises the steps:

[0062] (1) Preparation of starch phosphate: Dissolve 0.6 parts of sodium dihydrogen phosphate, 1.0 parts of disodium hydrogen phosphate, 1.6 parts of hydrogen peroxide and 5.85 parts of urea in 100 parts of water, and adjust to the required pH with dilute acid or dilute alkali. 5.0, then spray into 100 parts of starch under stirring, continue to stir for 30 minutes, heat up to 60-70°C under low vacuum, oxidize and dry and dehydrate until the water content is about 10%, stir and heat to 135°C on a fluidized bed dryer Phosphate reaction at ℃ for 1.0h, pulverized and sieved (160 mesh) to obtain starch phosphate. After testing, the degree of substitution DS of starch phosphate was 0.120, and the transparency of starch paste was 89.46%;

[0063] (2) Preparation of phase change fireproof slurry: Alkyd re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com