A kind of silicon integrated low optical loss magneto-optical film and preparation method thereof

An optical loss, magneto-optical technology, applied in vacuum evaporation coating, coating, sputtering and other directions, can solve the problem of high loss of thin film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the embodiments and the accompanying drawings.

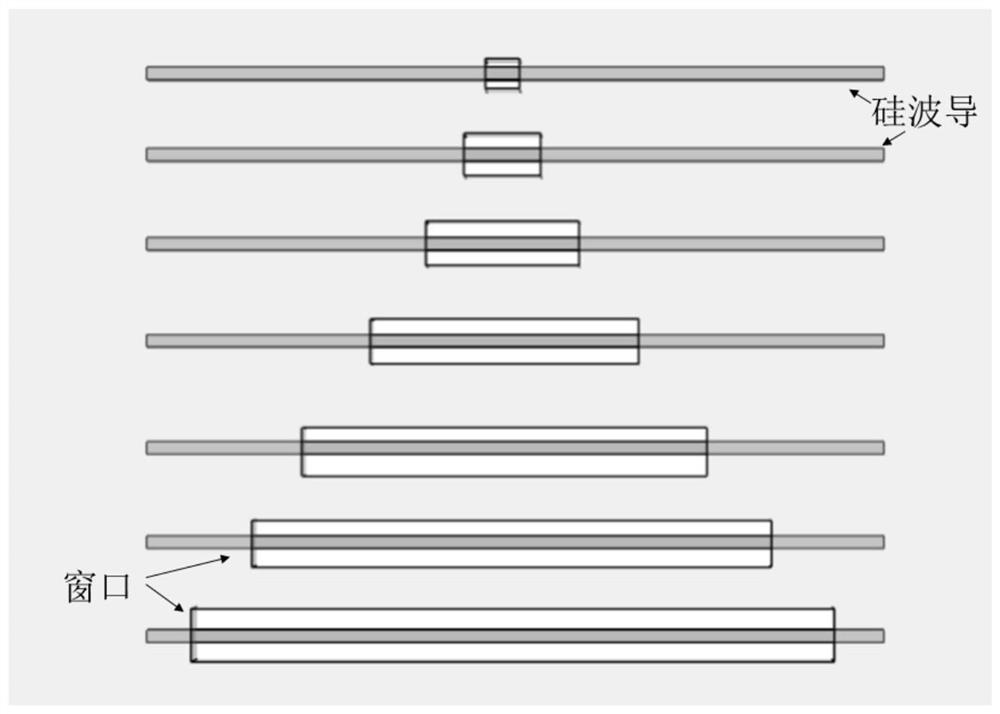

[0021] In order to accurately measure the optical loss of the thin film, the SOI substrate is patterned. The surface of the SOI substrate is cleaned with an organic solvent and deionized water, and the organic solvent includes acetone and ethanol. After exposure, development, and etching in sequence, a preset pattern such as figure 1 shown.

[0022] In order to obtain the underlying Si waveguide pattern and the cladding window pattern, two exposures, development, and etching are used. After exposure, development and etching for the first time, a Si waveguide pattern is obtained. After exposure, development and etching for the second time, a window pattern is formed on the waveguide.

[0023] Step 1: Deposit a layer of 10nm thick SiO on the SOI waveguide by sputtering 2 film. The sputtering power is 80W, the deposition rate is 1nm / min, the atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com