A kind of preparation method of single crystal vanadium dioxide thin film

A technology of vanadium dioxide and thin film, which is applied in the field of preparation of single crystal vanadium dioxide thin film, can solve the problems of high repeatability, high cost and harsh conditions, and achieve the effect of high repeatability, low annealing requirements and large deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

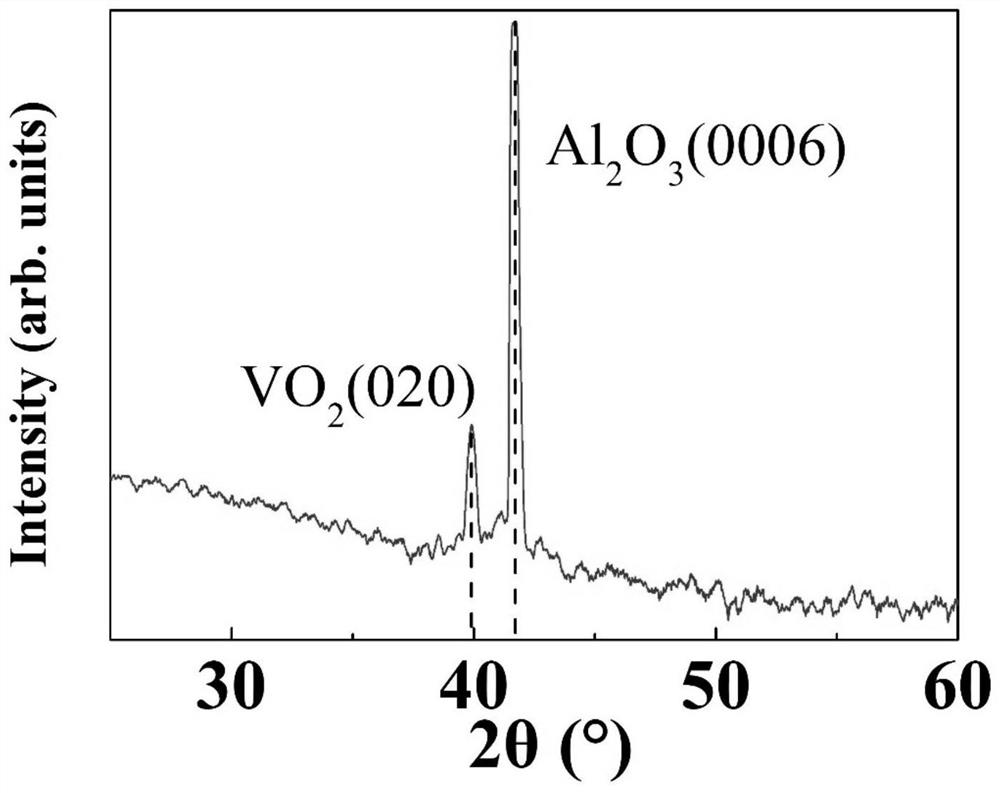

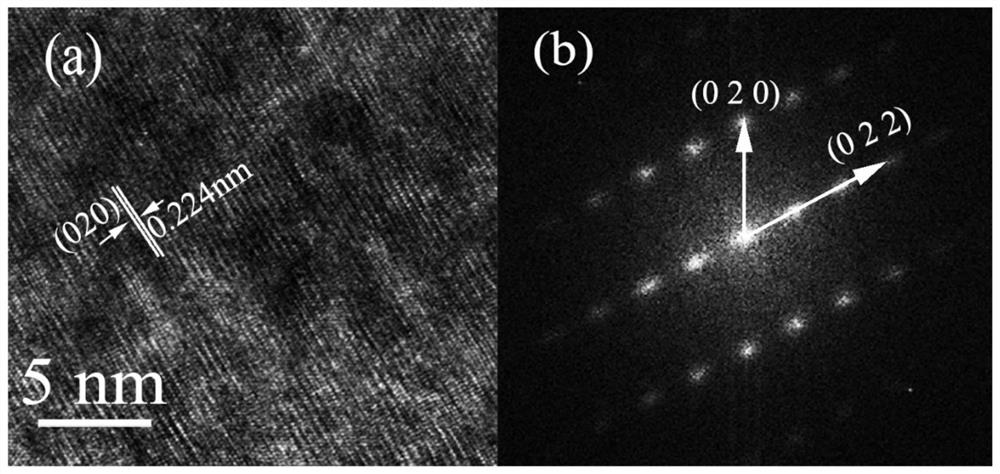

[0039] First, using the JPGF400B-G magnetron sputtering coating machine, using the method of DC magnetron sputtering on c-Al 2 o 3A metal vanadium thin film with extremely low resistivity is prepared on the substrate. The purity requirement of the magnetron sputtering metal vanadium target only needs to be greater than 99%, the target diameter is 60mm, the distance between the target and the substrate during magnetron sputtering coating is 180mm, and the substrate speed is 21.8rad / min; Pre-sputter the target for 15 minutes before coating, and then wait for the background vacuum to be 1.8×10 -3 After Pa is below, adjust the argon pressure to 1×10 -1 Under Pa, DC magnetron sputtering was carried out with a power of 140W for 5min.

[0040] The preparation parameters of the metal vanadium thin film are shown in Table 1 below:

[0041] Table 1 Preparation parameters of metal vanadium thin film

[0042] background vacuum Sputtering power sputtering gas Sputterin...

Embodiment 2

[0052] Directly give the specific preparation process using the traditional method, the traditional method: (refer to the patent a method for regulating the phase transition temperature of vanadium dioxide by rapid heat treatment, patent number: 201510824576.4, inventor: Liang Jiran, Li Jingpeng, Hou Luhui, Liu Xing).

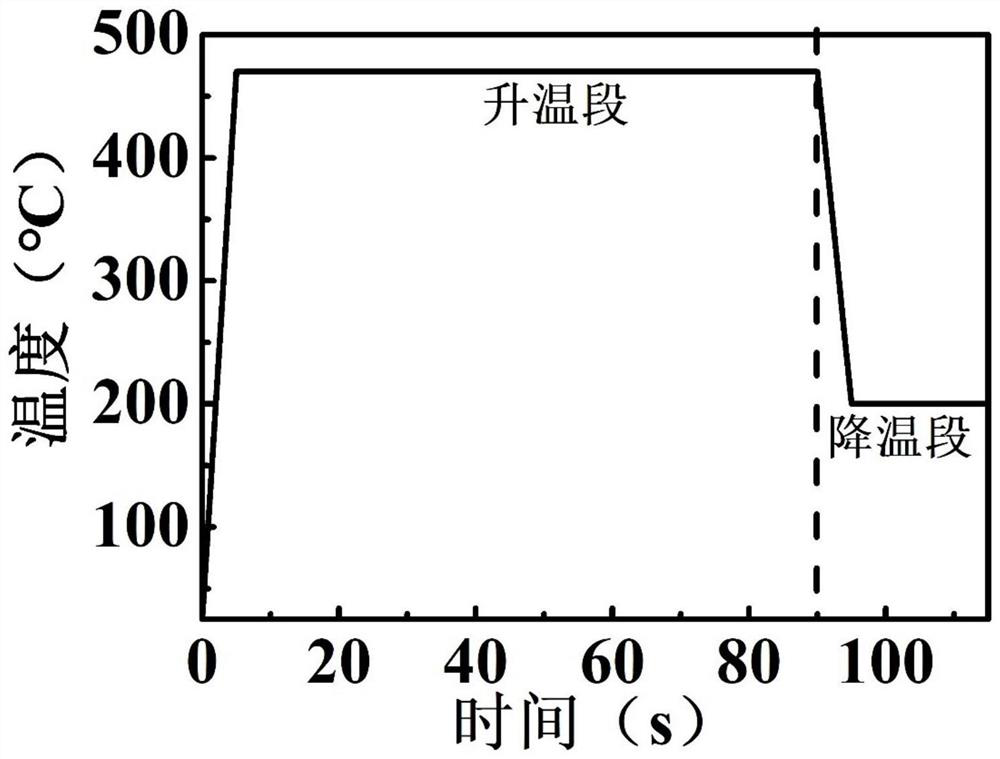

[0053] The sputtering pressure of metal vanadium thin film is 2×10 -0 Pa. The sputtering power is 75W, and the sputtering time is 10min-25min. After the end, the sample was taken out, the temperature was kept at 450°C, the heating time was 9s, the heating rate was 50°C / s, the holding time was 70s-170s, and the cooling time was 90s.

[0054] Result: the resistance-temperature change curve of embodiment 2 is as Image 6 As shown, the VO prepared by the traditional method 2 After the phase transition, the film can only achieve a change in the order of sheet resistance of about 3.1 orders of magnitude, the phase transition process is slow, and the hysteresis wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com