Textile of rapid self-purification chemical warfare agent simulant and preparation method of textile

A technology for chemical warfare agents and textiles, applied in chemical instruments and methods, textile/flexible product manufacturing, textiles and papermaking, etc., can solve problems such as high cost, complicated process technology, difficulty in satisfying actual industrial production, etc., and achieve adhesion The effect of the strong, easy approach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a kind of preparation method of the textile of above-mentioned rapid self-purification chemical warfare agent simulant, comprising the following steps:

[0034]S1. Prepare a polyphenolic compound solution and a 3-aminopropyltriethoxysilane solution with predetermined concentrations respectively, and then mix them uniformly to obtain a mixed solution;

[0035] S2, immersing the nonwoven fabric in the mixed solution obtained in step S1, taking it out after shaking and reacting in a constant temperature water bath, washing and drying to obtain the nonwoven fabric modified by the polyphenol hybrid coating;

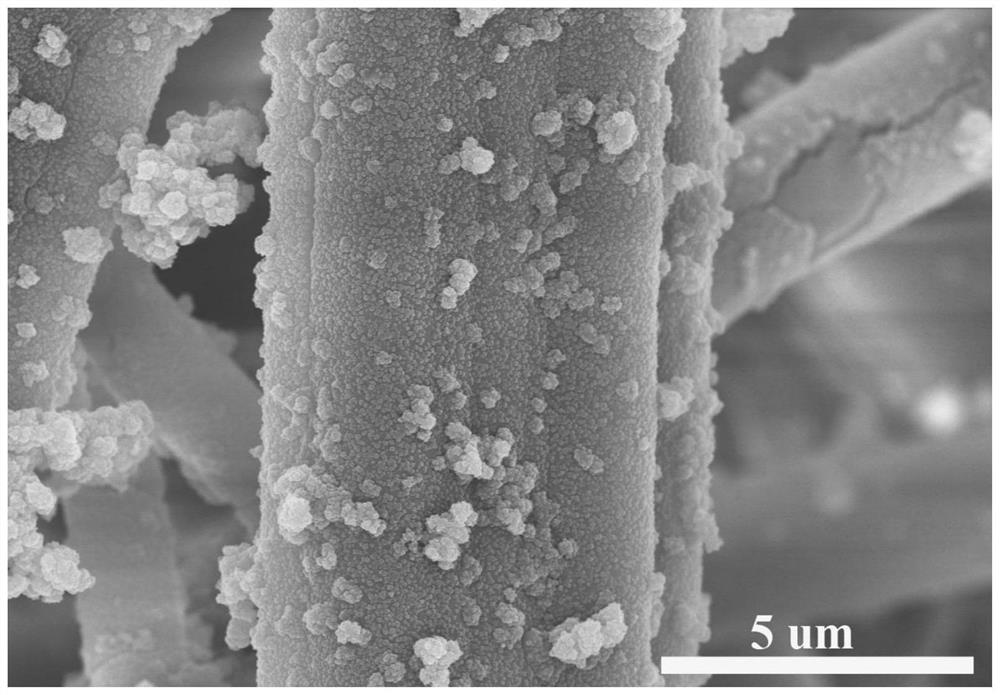

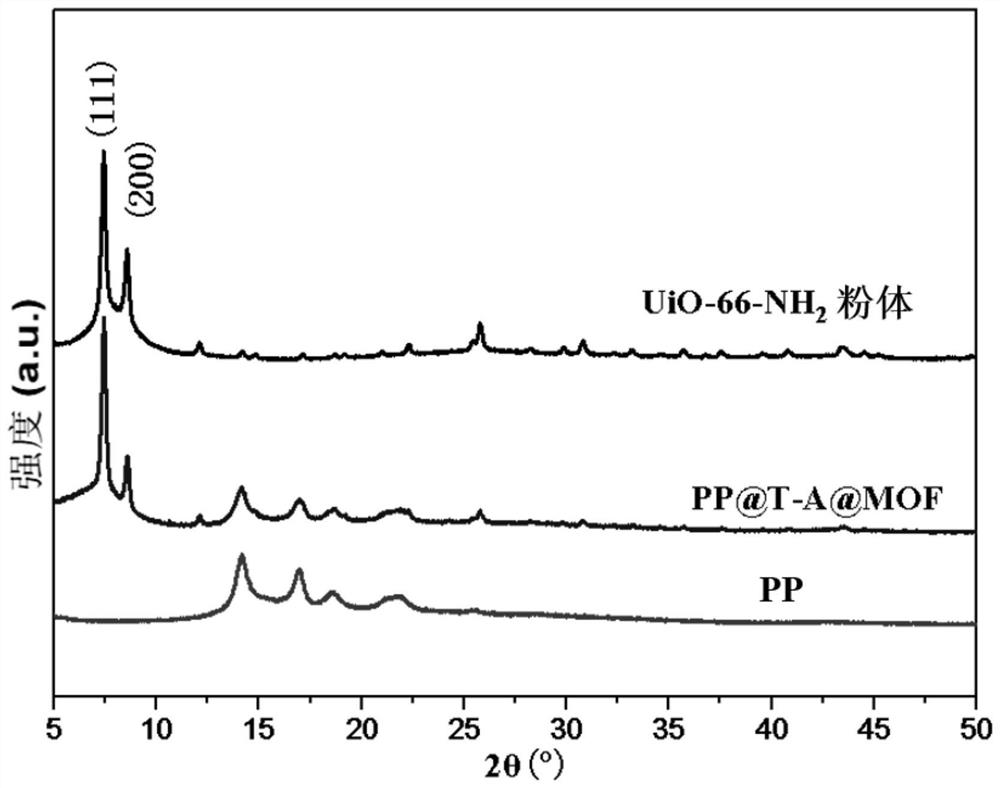

[0036] S3. Immerse the non-woven fabric modified by the polyphenol hybrid coating obtained in step S2 in an acetone solution containing zirconium tetrachloride and organic ligands, dissolve it ultrasonically, take it out after the hydrothermal reaction, and make the resulting The zirconium-based metal-organic framework compound is loa...

Embodiment 1

[0044] The present embodiment provides a kind of preparation method of the textile of fast self-purification chemical warfare agent simulant, comprises the steps:

[0045] S1. Dissolving 0.04g tannic acid (TA) in 20mL of tris-hydrochloric acid buffer solution with a pH of 8.5 to prepare a 2g / L tannic acid solution; then 0.04g 3-aminopropyl Triethoxysilane (APTES) is dissolved in the dehydrated alcohol of 4mL, the 3-aminopropyltriethoxysilane solution of preparation 10g / L; Above-mentioned two kinds of solutions are mixed, obtain mixed solution; In this mixed solution The mass ratio of tannic acid and 3-aminopropyltriethoxysilane is 1:1.

[0046] S2. Immerse 0.2 g of polypropylene (PP) nonwoven fabric ultrasonically washed with ethanol in the mixed solution obtained in step S1 at a bath ratio of 1:100, and keep the temperature at 30°C at an oscillation speed of 300r / min Water bath was shaken for 12 hours; then the nonwoven fabric was taken out, washed three times with deionized...

Embodiment 2~6

[0053] Embodiments 2 to 6 respectively provide a method for preparing textiles of fast self-purifying chemical warfare agent simulants. Compared with Embodiment 1, the difference is that some raw materials and corresponding parameters in the preparation process are adjusted, and the remaining steps are all It is consistent with Embodiment 1 and will not be repeated here. The raw materials and relevant process parameters corresponding to each embodiment are shown in Table 1.

[0054] Table 1 The corresponding raw materials and relevant process parameters of Examples 2 to 6

[0055]

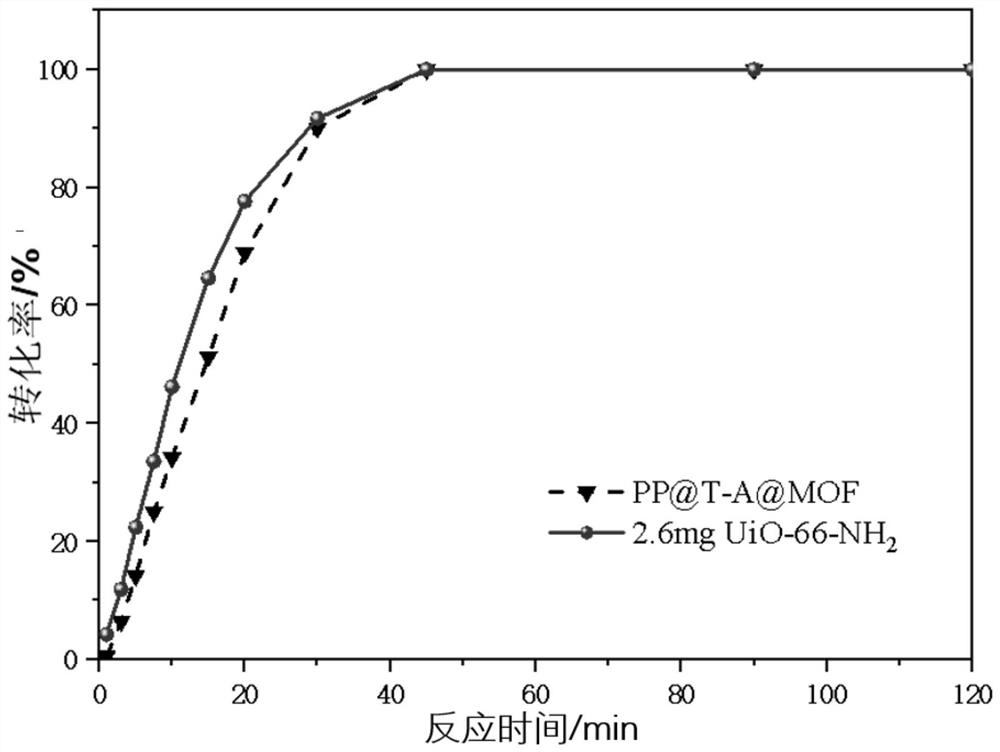

[0056] The degradation performance of the fast self-purifying chemical warfare agent simulants prepared in Examples 2 to 6 on the degradation performance of dimethyl 4-nitrophenylphosphate was tested, and the results are shown in Table 2.

[0057] The textiles prepared by table 2 embodiment 2~6 are to the degradability of 4-nitrophenyl phosphate dimethyl ester

[0058] Example Half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com