Polylactic acid fiber dyeing azo structured lactate type disperse dye and preparation method and dyeing process thereof

A technology of polylactic acid fibers and disperse dyes, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor sublimation fastness, low dye uptake rate, poor color fastness, etc., and achieve good fastness performance and dye uptake rate High, high dye uptake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

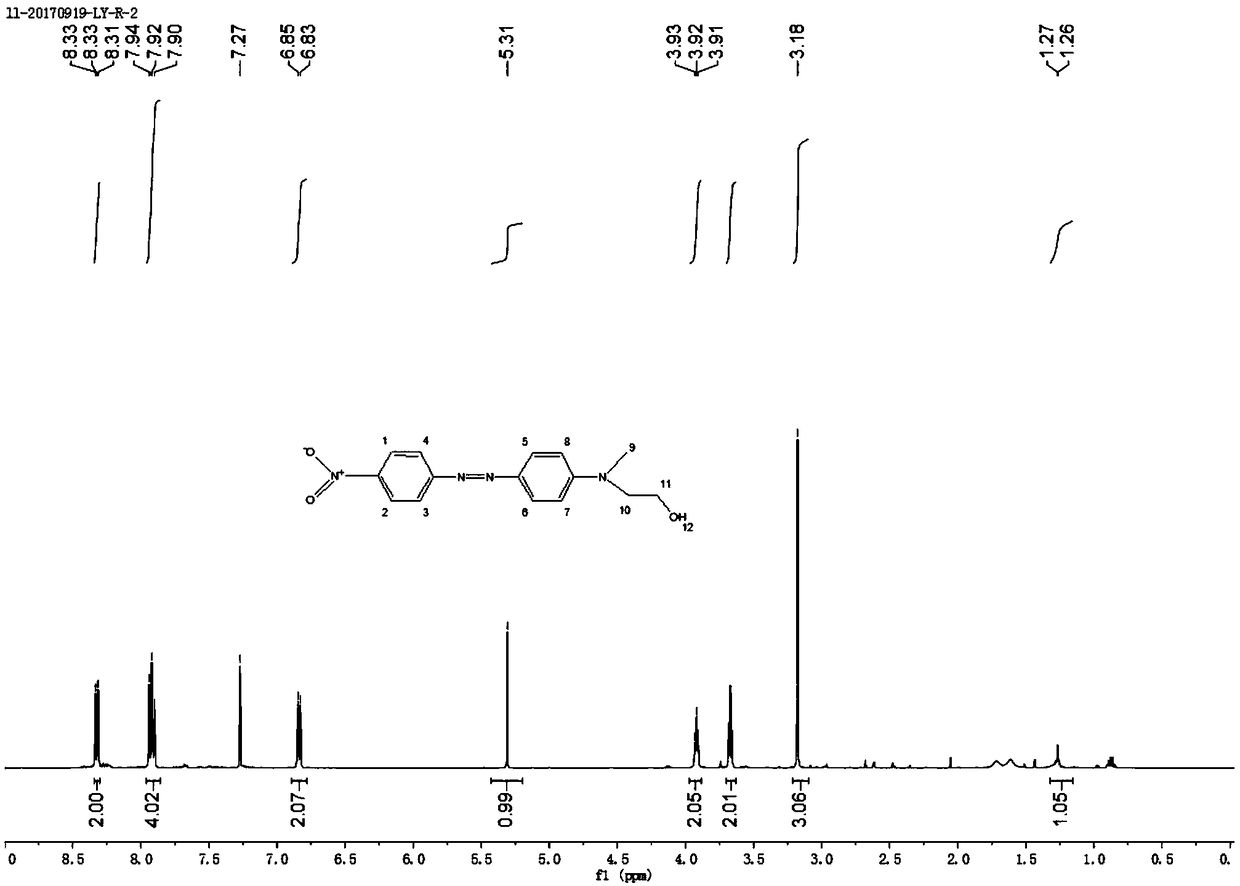

[0049] (1) Synthesis of disperse dyes containing hydroxyl groups

[0050] Weigh 1.38g of p-nitroaniline into a 50mL beaker, add 10mL of deionized water and 2.5mL of 12.5mol / L concentrated hydrochloric acid, heat to 70°C to dissolve it, and add a small amount of crushed ice to the beaker after it is completely dissolved , stirring continuously under the ice-water bath until the temperature of the solution in the beaker reaches 0-5° C., adding a sodium nitrite solution containing 0.86 g (25% in excess) for diazotization, and the diazotization reaction ends after 30 minutes;

[0051] Add 5mL of deionized water and 2mL of 12.5mol / L concentrated hydrochloric acid to N-methyl-N-hydroxyethylaniline, shake and dissolve, pour into a 150mL beaker, stir in an ice-water bath to 0-5°C, and pour The diazo component obtained above is added dropwise to carry out the coupling reaction, and 10% NaCO is used in the process 3 Adjust the pH value of the solution so that the entire coupling proces...

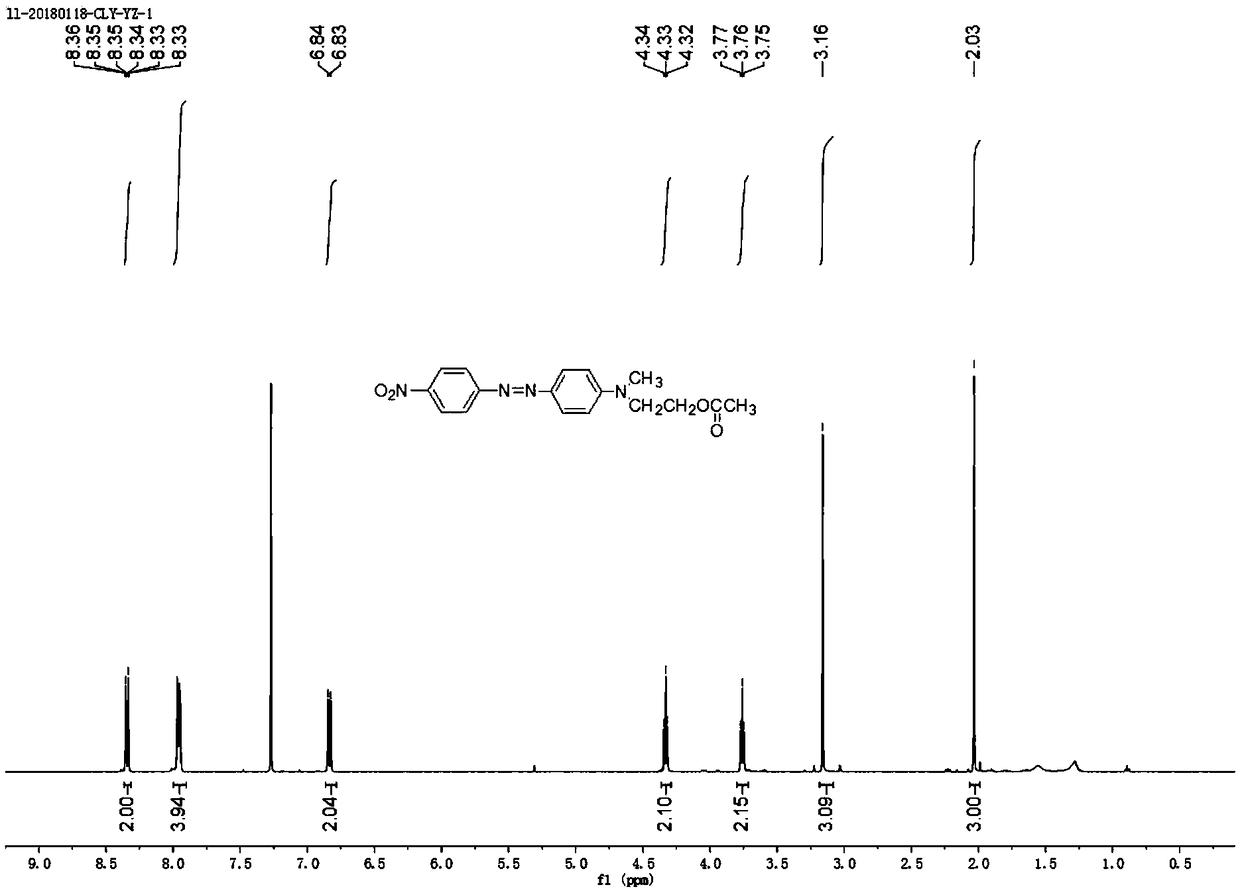

Embodiment 2

[0075] Weigh 3.42g (10mmol) of C.I. Disperse Red 19, 3.176g (30mmol) of lactic acid, 0.6mmol of concentrated sulfuric acid, and 130mL of toluene in a 250ml three-neck flask equipped with a reflux condenser, and heat the reaction to reflux for 8 hours. The reaction is detected by TLC until the end point. After the end point is reached, the solvent is removed by rotary evaporation to obtain a lactic acid ester type disperse dye with a purity of 99.2% and a yield of 97.3%. Its structural formula is as follows:

[0076]

[0077] The polylactic acid fiber is dyed with an azo-structure lactate type disperse dye for nuclear magnetic resonance detection, and its hydrogen nuclear magnetic resonance spectrum is as follows: Figure 5 . 1H NMR (400MHz, CDCl3) δ8.42–8.24(m,1H),7.99–7.84(m,2H),6.90–6.82(m,1H),4.27(ddd,J=11.7,10.4,5.4Hz,1H ), 3.80(t, J=6.1Hz, 2H), 3.71–3.53(m, 1H), 1.40(dd, J=10.1, 4.3Hz, 3H).

[0078] PLA fabric is dyed with the lactate type disperse dye that obtains i...

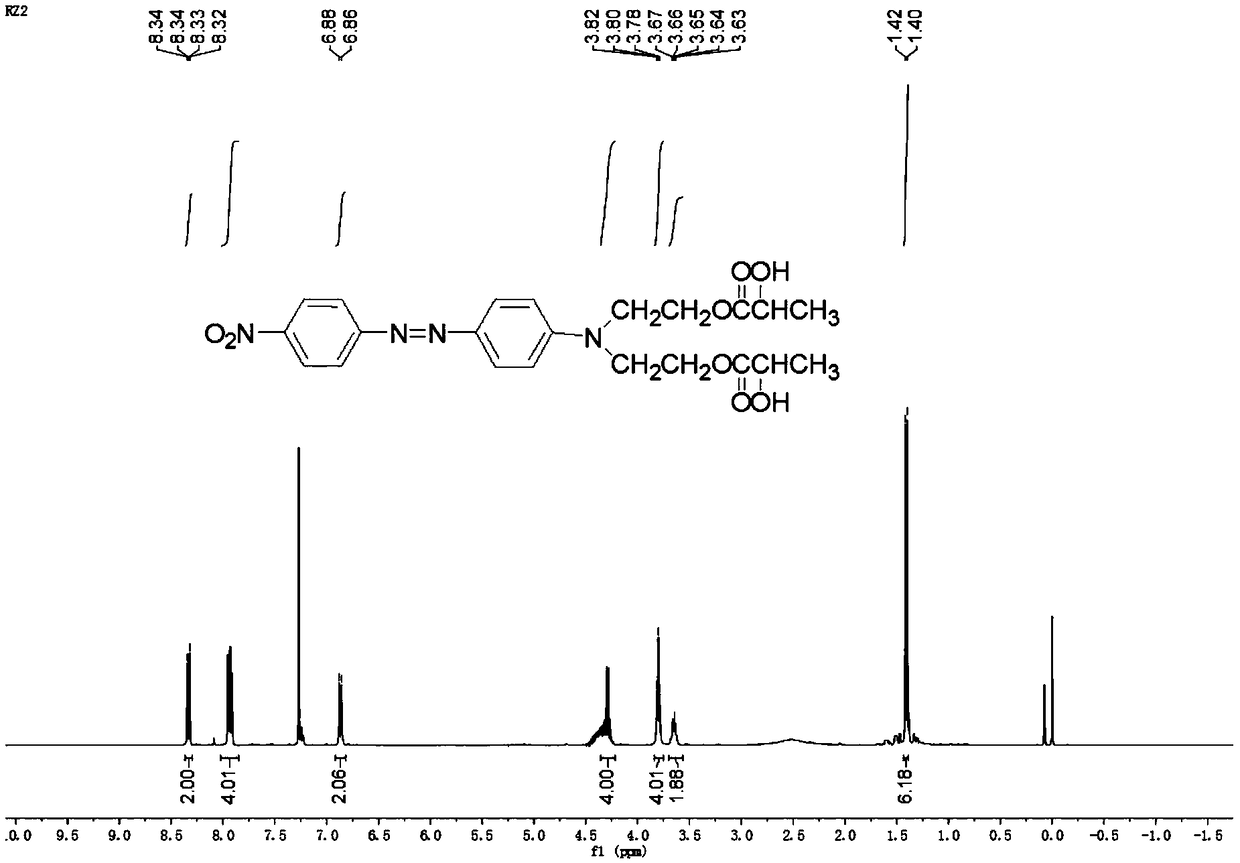

Embodiment 3

[0080] Change the C.I. Disperse Red 19 in Example 2 to C.I. Disperse Orange, the molar weight of the raw materials remains unchanged, heat the reaction under magnetic stirring to reflux for 6 hours, and use the TLC method to detect the reaction to the end point, and the remaining steps are the same as in Example 2 to obtain polylactic acid The azo-structure lactate type disperse dye for fiber dyeing has a purity of 99.0% and a yield of 93.4%. Its structural formula is as follows:

[0081]

[0082]PLA fabric is dyed with the lactate type disperse dye that obtains among the embodiment 3, dyeing process is as follows: get polylactic acid fiber dyeing with azo structure lactate type disperse dye 0.5g, dispersant NNO 0.5g, zirconium bead 60g (diameter 0.8mm), 10mL of water was added to the sand mill and sanded for 10 hours. After the sanding was completed, the dye dispersion was collected by filtering through a fine nylon filter cloth and fixed in a 250mL volumetric flask to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com