Armor of high-strength polyurethane/ceramic structure

A polyurethane, high-strength technology, applied in the structure of armor plates, protective equipment, armor, etc., can solve the problems of human tissue and bone damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

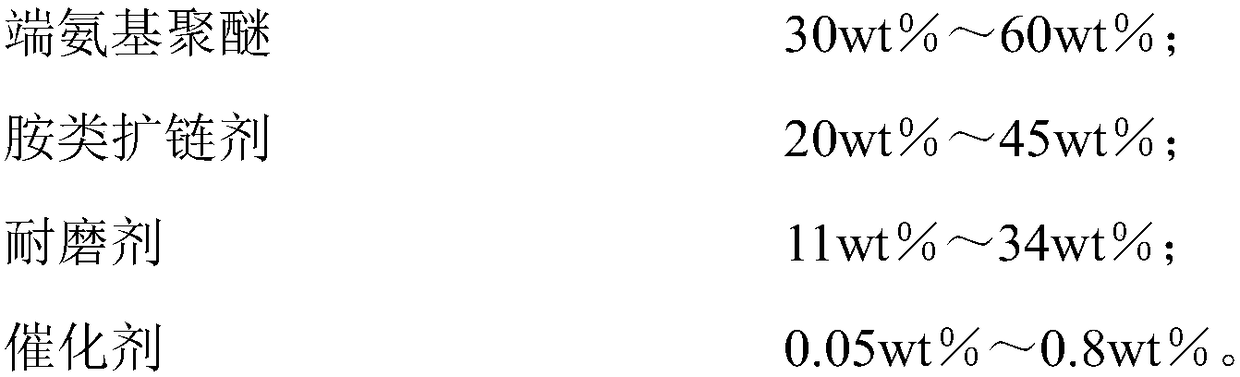

Method used

Image

Examples

Embodiment 1

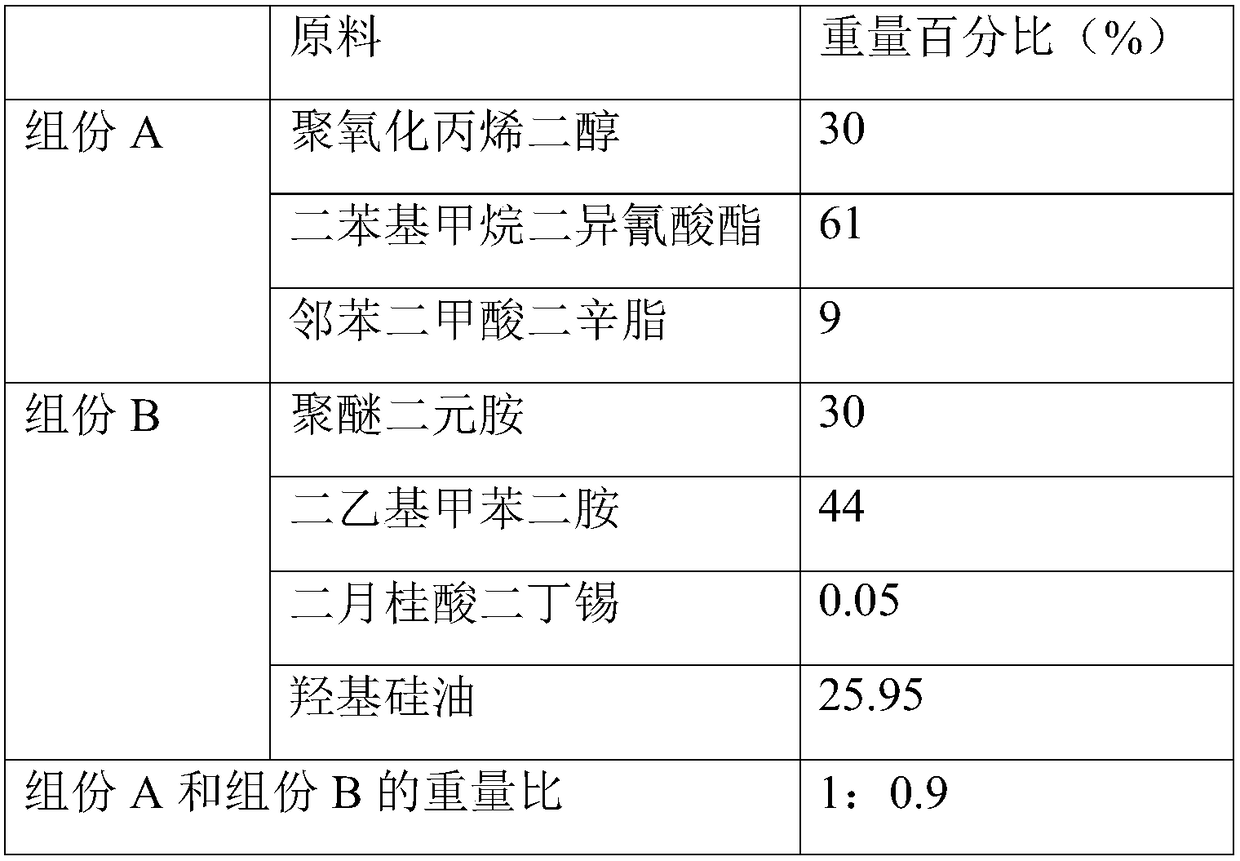

[0049] The contents of each raw material in component A and component B in this embodiment are shown in Table 1.

[0050] (1) Carry out vacuum dehydration process to 30 weight parts of polyoxypropylene diols, polyoxypropylene diols after dehydration and 61 weight parts of diphenylmethane diisocyanates, 9 weight parts of dioctyl phthalates in inert gas In the atmosphere, react at 35°C for 6h, cool and discharge to obtain component A;

[0051] (2) 30 parts by weight of polyether diamine, 44 parts by weight of diethyltoluenediamine, and 25.95 parts by weight of hydroxyl silicone oil are dehydrated under reduced pressure in a reaction kettle, and then 0.05 parts by weight of dibutyltin dilaurate are added, Stir at 35° C. for 4 h, ultrasonicate for 30 min, cool and discharge to obtain Component B.

[0052] Table 1: Content of each raw material in component A and component B in embodiment 1

[0053]

Embodiment 2

[0055] The contents of each raw material in component A and component B in this embodiment are shown in Table 2.

[0056] (1) Carry out vacuum dehydration treatment to 59.7 parts by weight of polytetrahydrofuran diol, polytetrahydrofuran diol after dehydration and 30 parts by weight of toluene diisocyanate, 10.3 parts by weight of butyl phthalate in an inert gas atmosphere, at 100 ℃ The reaction was carried out for 2 hours, cooled and discharged to obtain component A;

[0057] (2) 60 parts by weight of polyether triamine, 28.2 parts by weight of 4,4'-bis-sec-butylaminodiphenylmethane, and 11 parts by weight of polytetrafluoroethylene micropowder were dehydrated under reduced pressure in a reactor, and then added 0.8 parts by weight of stannous chloride, stirred at 80° C. for 1 hour, ultrasonicated for 5 minutes, cooled and discharged to obtain Component B.

[0058] Table 2: Content of each raw material in component A and component B in embodiment 2

[0059]

[0060]

Embodiment 3

[0062] The contents of each raw material in component A and component B in this embodiment are shown in Table 3.

[0063] (1) Carry out vacuum dehydration treatment to 48 parts by weight of tetrahydrofuran-oxypropylene glycol, and dehydrated tetrahydrofuran-oxypropylene glycol with 49 parts by weight of dicyclohexylmethane diisocyanate and 3 parts by weight of propylene carbonate in an inert gas atmosphere , reacted at 85°C for 3h, cooled and discharged to obtain component A;

[0064] (2) 45.5 parts by weight of polyether diamine, 20 parts by weight of azodicarbonamide, and 34 parts by weight of graphene oxide were dehydrated under reduced pressure in a reaction kettle, and then 0.5 parts by weight of stannous octoate was added, and at 60° C. Stir for 2 hours, ultrasonic for 15 minutes, then cool and discharge to obtain component B.

[0065] Table 3: Content of each raw material in component A and component B in embodiment 3

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com