Low-power-loss laser pumping source system

A laser pumping and electrical loss technology, applied in lasers, laser parts, laser monitoring devices, etc., can solve problems such as reducing output current stability, burning out power tubes, and reducing overall efficiency, improving safety, preventing The effect of repeated actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

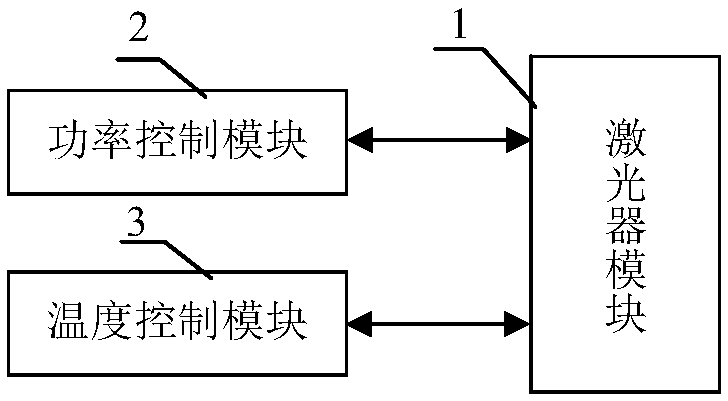

[0037] Embodiment 1 Overall structure of the system

[0038] Such as figure 1 As shown, the system structure includes a laser module 1, a power control module 2, and a temperature control module 3. Both the power control module 2 and the temperature control module 3 are connected to the laser module 1, and the power control module 2 provides driving current to the laser module 1, and the temperature control module Module 3 is responsible for controlling the working temperature of the laser module to make it work at a constant temperature.

Embodiment 2

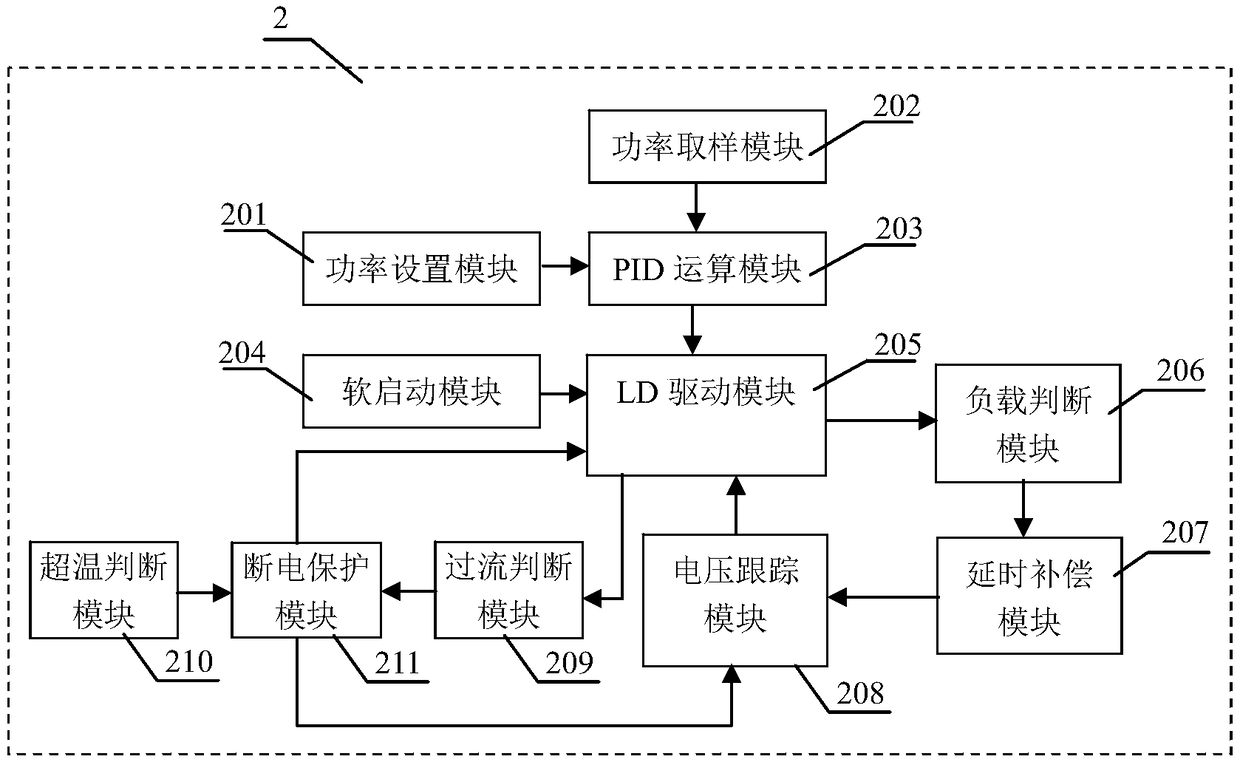

[0039] Embodiment 2 The structure of the power control module 2 of the present invention

[0040] The structure of the power control module 2 is as figure 2 As shown, it includes a power setting module 201, a power sampling module 202, a PID calculation module 203, a soft start module 204, an LD driver module 205, a load judging module 206, a delay compensation module 207, a voltage tracking module 208, and an overcurrent judging module 209 , an over-temperature judging module 210 and a power-off protection module 211. The required power is set by the power setting module 201, and the power sampling module 202 samples the output optical power through the photodiode (PD) integrated in the laser module 1 and converts it into a voltage, and then performs PID calculation with the voltage set by the power setting module 201 In the module 203, the difference is calculated and the PID operation is performed. The result of the operation is output to the LD drive module 205 and contro...

Embodiment 3

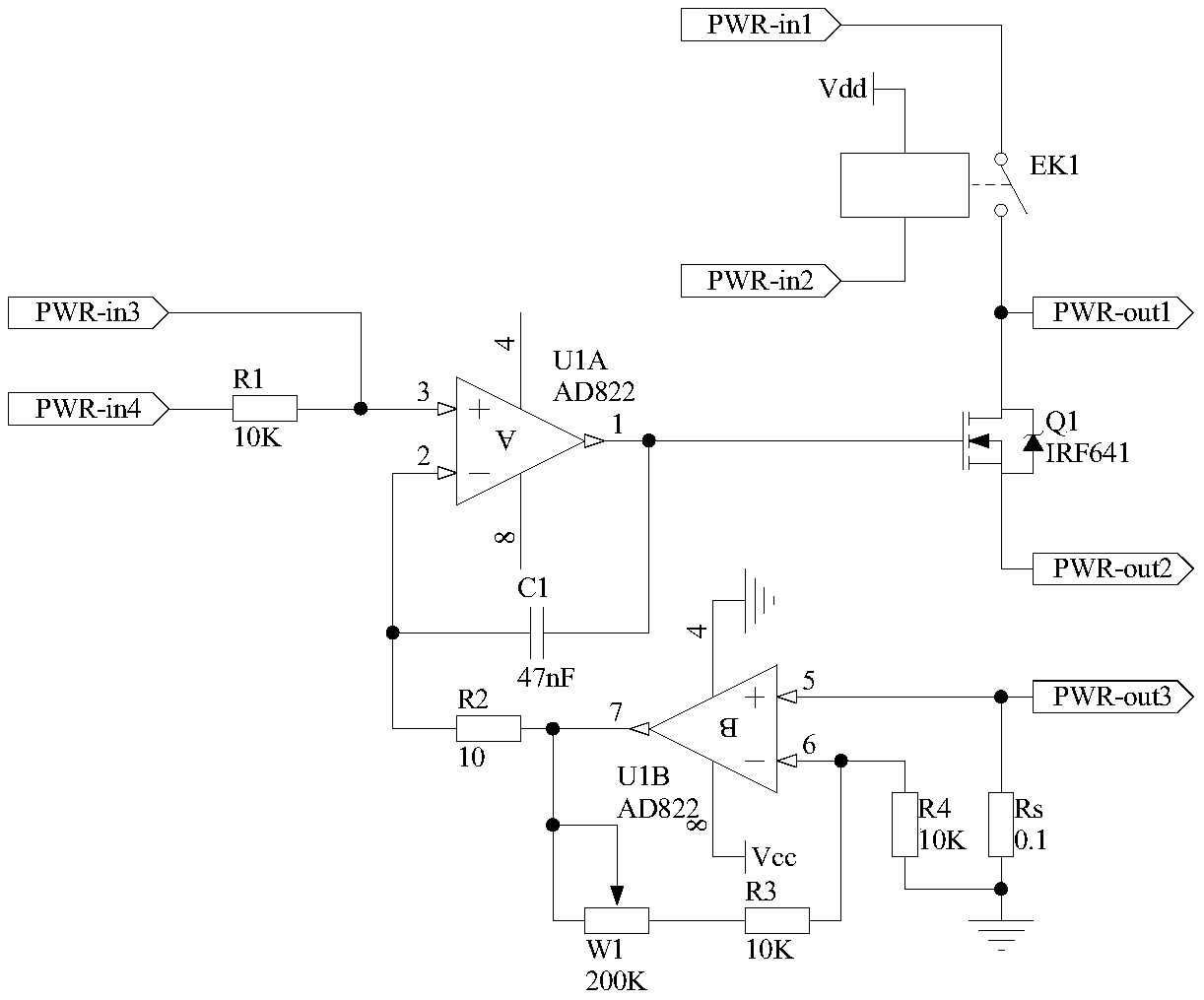

[0044] Embodiment 3 The load judging module of the present invention

[0045] The structure of the load judging module 206 of the present invention is as follows Figure 4As shown: the non-inverting input terminal of the operational amplifier U2A is used as the first input terminal of the load judgment module 206, which is denoted as port Vjdg-in1, and is connected to the port PWR-out1 of the LD driver module 205, and the inverting input terminal of the operational amplifier U2A is connected to the The output terminal of operational amplifier U2A is connected to one end of resistor R5, the other end of resistor R5 is connected to one end of resistor R6 and the same-inverting input terminal of operational amplifier U3A, the other end of resistor R6 is grounded, and the output terminal of operational amplifier U3A is connected to the in-phase input terminal of operational amplifier U3A. One end is connected to one end of the resistor R9, the other end of the resistor R8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com